A kind of preparation method and application of β-galactosidase

A technology of galactosidase and galactose, applied in the field of preparation of β-galactosidase, which can solve the problems of long fermentation period of β-galactosidase, inability to use genetically modified strains, restrictions on the use of cross-linking agents, etc. , to achieve the effect of increasing personnel burden and equipment investment, shortening production cycle, and high specific vitality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1: Preparation of β-galactosidase

[0066] A preparation method of β-galactosidase, comprising the following steps:

[0067] (1) Inoculate 1 loop of Bacillus circulans (purchased from the American Type Culture Collection (ATCC), No. 31382) into 50 mL of LB medium, and culture it at 37°C for 18 hours to activate it. Bacillus spp. was added to an Erlenmeyer flask containing 500mL of LB medium, shaken and cultivated at 37°C and 180rpm for 6 hours, and then inoculated into a seed tank for cultivation to obtain a seed culture solution;

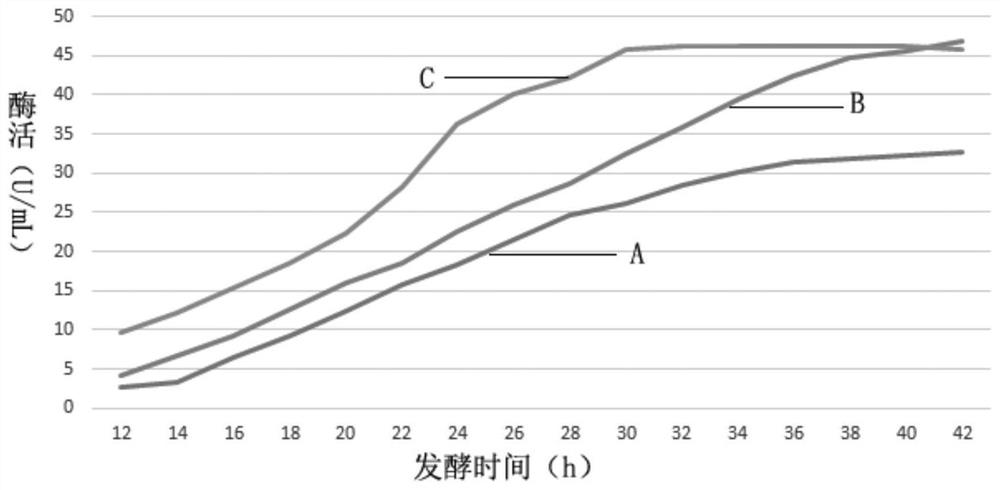

[0068] (2) the seed culture liquid that step (1) is made adds in the fermentor of 200L that contains 120L fermentation medium and ferments, and the pH in the fermentor is adjusted to be 6.64 with 10% (mass fraction) sodium hydroxide solution, at 37 At ±0.5°C, stirring speed 180rpm, ventilation rate 120L / min, ferment for 8 hours, after 8 hours, adjust the pH value to 7.45±0.5 with hydrochloric acid, after 12 hours, take samples at...

Embodiment 2

[0071] Embodiment 2: Preparation of β-galactosidase

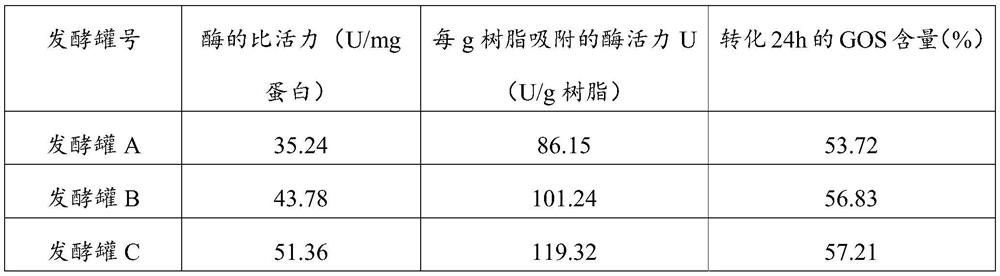

[0072] The difference between Example 2 and Example 1 is that in step (1) Bacillus circulans CCTCC NO: M2015424 was used instead of Bacillus circulans (purchased from the American Type Culture Collection (ATCC), No. 31382), and fermented for 30 h 115L of Bacillus circulans fermentation broth with an enzyme activity of 46.3U / mL was obtained; 46.0L of enzyme fluid with an enzyme activity of 107.6U / mL was obtained after microfiltration to remove bacteria and 50KD membrane concentration.

Embodiment 3

[0073] Embodiment 3: the preparation of the immobilized enzyme of β-galactosidase

[0074] 1. Refining of crude enzyme

[0075] Take 46L of the enzyme solution obtained by concentrating in Example 2, slowly add 6.9kg of ammonium sulfate to it, and after the ammonium sulfate is completely dissolved, let it stand at 6°C for 1 hour, then use a 50KD membrane to clean the enzyme solution to obtain 46.8L of enzyme solution Refined β-galactosidase solution with an activity of 102.1U / mL and a conductivity of 7.84ms / cm (that is, in every 1mL of β-galactosidase solution, the enzyme activity of β-galactosidase is 102.1U).

[0076] 2. Preparation of immobilized enzyme of β-galactosidase

[0077] A method for preparing an immobilized enzyme of β-galactosidase, comprising the following steps:

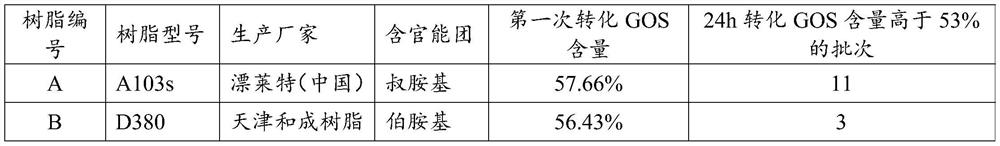

[0078] Soak 42Kg of macroporous styrene series weakly basic anion exchange resin A103s (this resin is provided by Brilliant (China) Co., Ltd., and the resin aperture is 30-50nm) in deionized water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com