Plating assistant agent for zinc-aluminum-nickel-rare earth-alloy hot-dip plating and technological method

A rare-earth alloy and hot-dip galvanizing technology, which is applied in hot-dip galvanizing process, metal material coating process, coating, etc., can solve the problem of missing plating on the surface of steel parts and the restriction of hot-dip galvanized aluminum-nickel rare earth alloy layer, etc. problems, to achieve the effect of reducing the generation of zinc slag, preventing splashing of plating solution, and improving activity and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

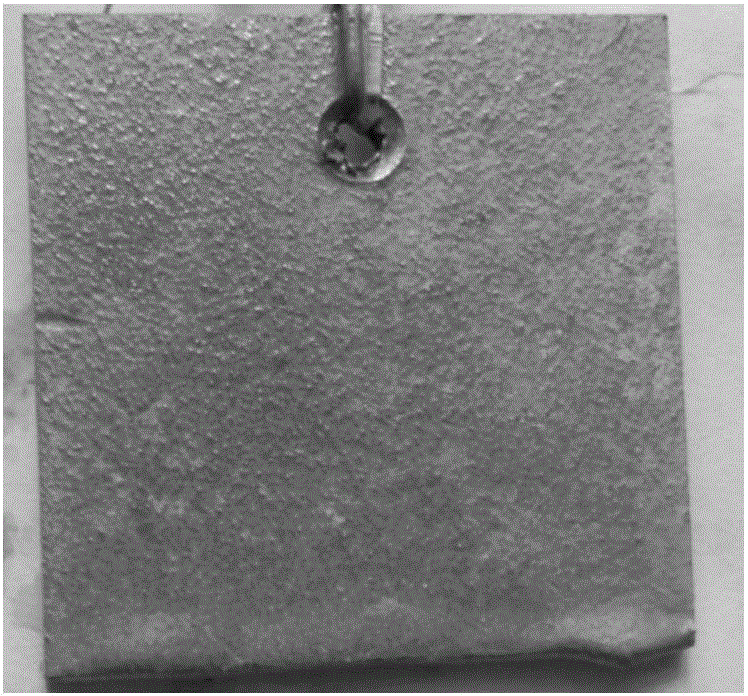

Image

Examples

experiment example 1

[0035] Get 20g of zinc chloride, 15g of ammonium chloride, 6g of stannous chloride, and 0.1g of urotropine; strictly make A solution according to the above-mentioned step one; get ethanol 25g, nonionic surfactant (NP-10) 0.80 G, cationic surfactant (tetradecyl dimethyl benzyl ammonium chloride) 1g; Strictly make B solution (compound active agent) by above-mentioned steps 2;

[0036] Get compound active agent 200mL and add in the 500mL beaker that 200mL A solution is housed, fully stir and make experimental plating flux; This flux formula is: the zinc chloride of 10g / L, the chlorine of 7.5g / L Ammonium chloride, stannous chloride of 3g / L, urotropine of 0.05g / L, ethanol of 12.5g / L, nonionic surfactant of 0.40g / L, cationic surfactant of 0.50g / L, The rest is deionized water.

[0037] According to the hot-dip plating experiment, after using the plating flux, the plating layer on the surface of the steel sheet has the phenomenon of missing plating, and the surface of the plating lay...

experiment example 2

[0039] Get 30g of zinc chloride, 25g of ammonium chloride, 15g of stannous chloride, and 0.1g of urotropine; strictly make A solution according to the above step 1; get 50g of ethanol and 1g of nonionic surfactant (NP-10) respectively , cationic surfactant (tetradecyldimethylbenzyl ammonium chloride) 1.50g; Strictly make B solution (compound active agent) by above-mentioned steps 2;

[0040] Get compound active agent 200mL and add in the 500mL beaker that 200mL A solution is housed, fully stir and make experimental plating flux; This flux formula is: the zinc chloride of 15g / L, the chlorine of 12.5g / L Ammonium chloride, stannous chloride of 7.5g / L, urotropine of 0.05g / L, ethanol of 25g / L, nonionic surfactant of 0.50g / L, cationic surfactant of 0.75g / L, The rest is deionized water.

[0041] According to the hot-dip plating experiment, the quality of the coating on the surface of the steel sheet is good after using the flux, and there is no missing plating phenomenon, and the co...

experiment example 3

[0043]Get 45g of zinc chloride, 30g of ammonium chloride, 20g of stannous chloride, and 0.2g of urotropine; strictly make A solution according to the above-mentioned step one; get ethanol 80g, nonionic surfactant (NP-10) 1.40 G, cationic surfactant (tetradecyl dimethyl benzyl ammonium chloride) 2g; Strictly make B solution (compound active agent) by above-mentioned steps 2;

[0044] Get compound active agent 200mL and add in the 500mL beaker that 200mL A solution is housed, fully stir and make experimental plating flux; This flux formula is: the zinc chloride of 22.5g / L, the chlorine of 15g / L Ammonium chloride, stannous chloride of 10g / L, urotropine of 0.1g / L, ethanol of 40g / L, nonionic surfactant of 0.70g / L, cationic surfactant of 1g / L, and the rest are Deionized water.

[0045] According to the hot-dip plating experiment, the quality of the coating on the surface of the steel sheet is good after using the flux, and there is no missing plating phenomenon, and the coating sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com