Nitric acid-free acid washing method of hot-rolled 409L ferrite stainless steel

A nitric acid and stainless steel technology, applied in the field of stainless steel pickling, can solve the problems of high acid consumption, high nitrogen oxide purification cost, high nitrate-containing wastewater treatment cost, nitrogen oxide waste gas and nitrogen-containing wastewater treatment cost, and the like. achieve the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

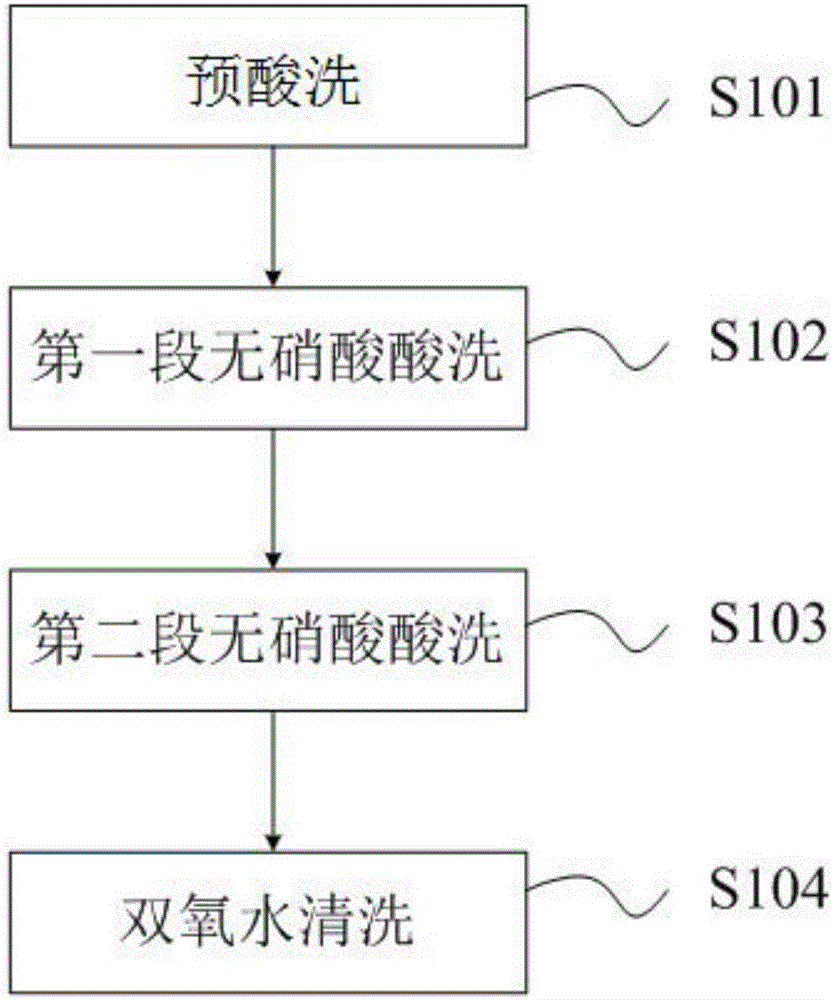

[0028] Such as figure 1 , The embodiment of the present invention relates to a nitric acid-free pickling method for hot-rolled 409L ferritic stainless steel, comprising the following steps:

[0029] (1) S101, pre-pickling step: dipping the steel strip into a pre-pickling solution for pickling. Among them, the pre-pickling liquid is preferably sulfuric acid pickling liquid, of course, other acid solutions, such as nitric acid, or a mixed acid solution of sulfuric acid and nitric acid, etc. can also be used. Taking sulfuric acid pickling as an example, in the sulfuric acid pickling solution, H 2 SO 4 The concentration is 150-170g / L, and the metal ion concentration is 30-40g / L. Among them, the temperature of the sulfuric acid pickling solution is preferably controlled within the range of 75-85° C., so that better sulfuric acid pickling effect can be obtained. The pickling time is preferably controlled within the range of 25-50s, which can control the steel strip from being pi...

Embodiment 2

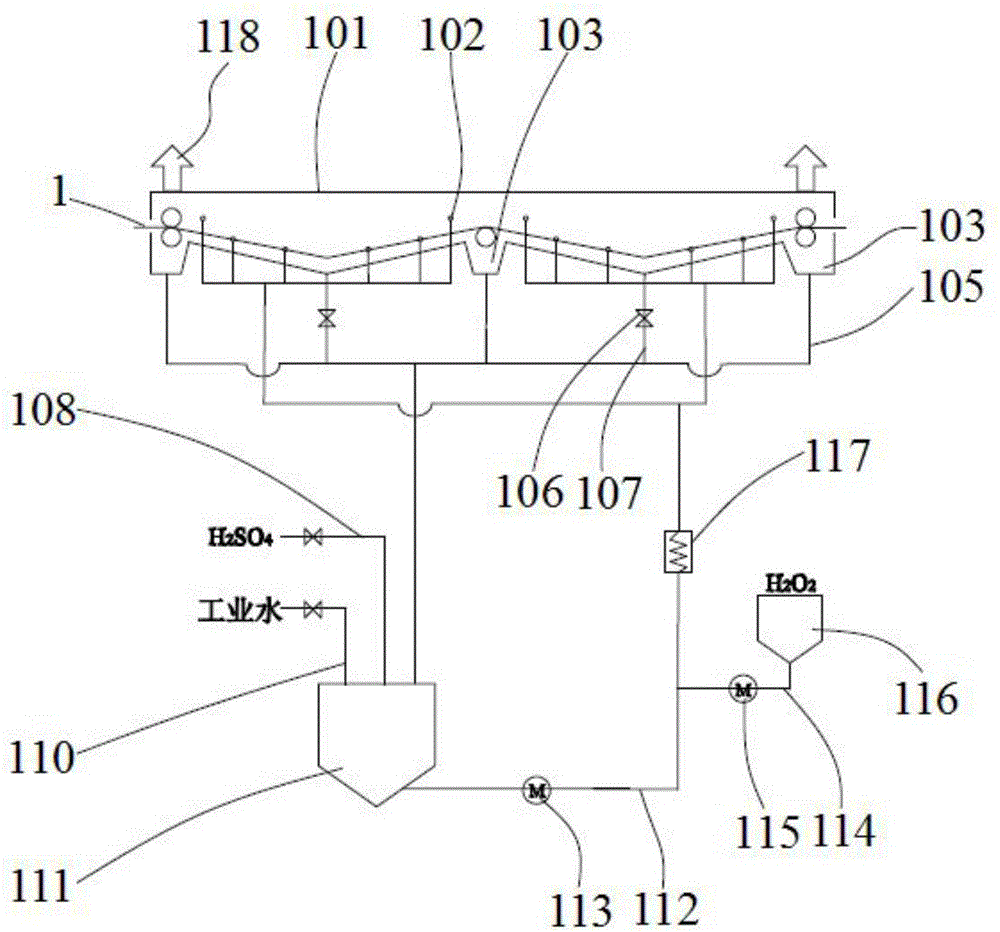

[0044] Such as figure 2 , the embodiment of the present invention provides a stainless steel pickling liquid supply mechanism for supplying pickling liquid to the nozzle 102 in the stainless steel strip pickling section, which includes an acid liquid supply pipeline 112, and the acid liquid supply pipeline 112 A pickling solution preparation structure is connected, and the pickling solution preparation structure includes a concentrated sulfuric acid distribution pipe 108, a water distribution pipe 110 and a hydrogen peroxide distribution pipeline 114; the above-mentioned concentrated sulfuric acid distribution pipe 108 is used to supply concentrated sulfuric acid, and the water distribution pipe 110 is used to supply Industrial water, hydrogen peroxide distribution pipeline 114 is used to supply hydrogen peroxide. The inlet end of the acid supply pipeline 112 is connected with an acid distribution tank 111, the concentrated sulfuric acid distribution pipe 108 and the water di...

Embodiment 3

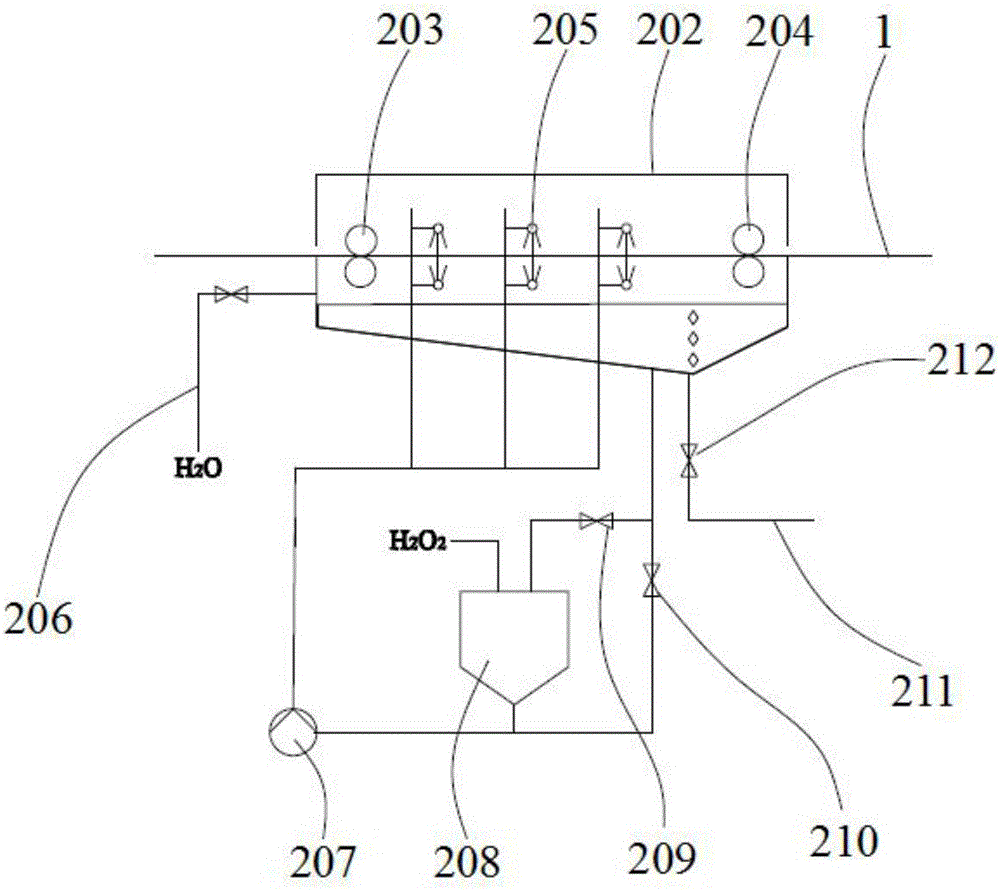

[0050] Such as image 3 , the embodiment of the present invention provides a cleaning device for nitric acid-free pickling of steel strip 1, the cleaning device is installed at the outlet of the pickling section, and is used for cleaning the steel strip 1 that has been pickled without nitric acid. The cleaning device comprises a cleaning tank 202, the inlet of the cleaning tank 202 is arranged near the outlet of the pickling section, and a backup roller 203 and a squeeze roller 204 are arranged in the cleaning tank 202, and the backup roller 203 is arranged near the inlet of the cleaning tank 202, and the squeeze roller The roller 204 is disposed near the outlet end of the cleaning tank 202 . The cleaning device also includes a blowing mechanism for blowing the cleaning medium, and the blowing mechanism is located in the cleaning tank 202; as image 3, the above-mentioned blowing mechanism includes multiple groups of nozzle groups, and multiple groups of nozzle groups are seq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com