Method for adjusting three-dimensional photonic crystal band gap through lithiation method

A photonic crystal and three-dimensional technology, which is applied in the field of adjusting the band gap of three-dimensional photonic crystals, can solve the problems of narrow adjustment range and low precision, and achieve the effect of large adjustment range, high precision and safe operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

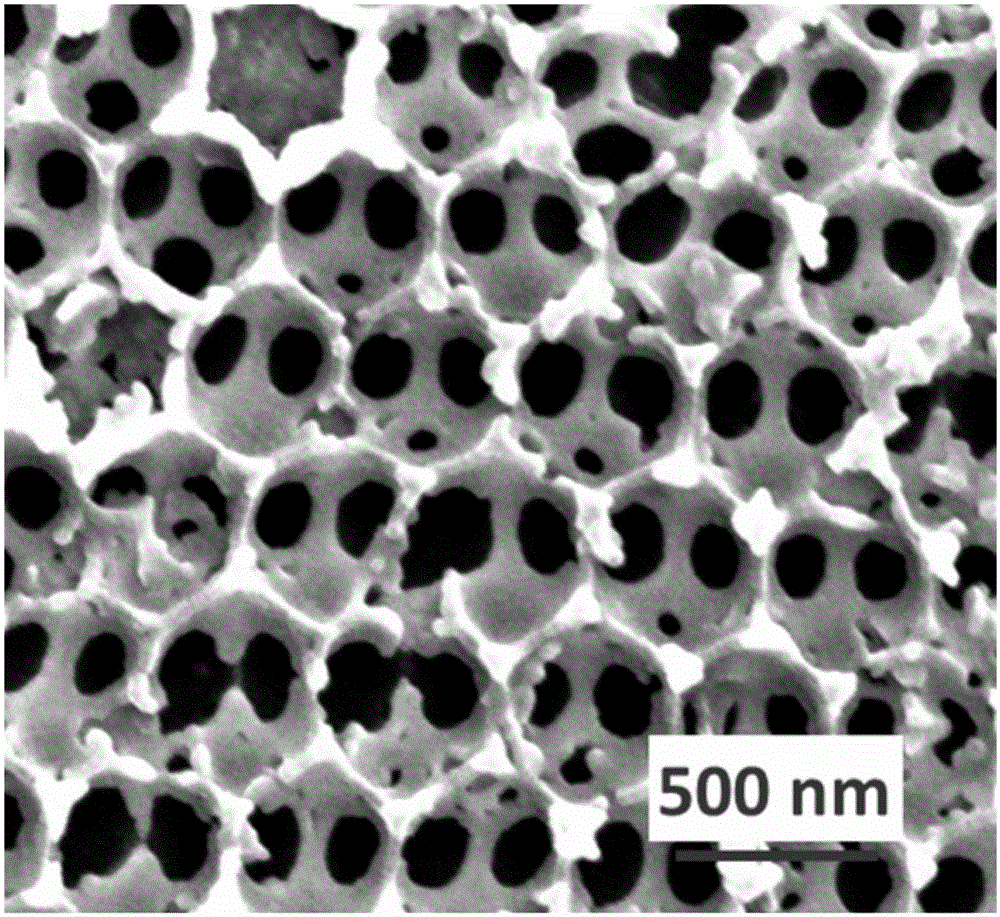

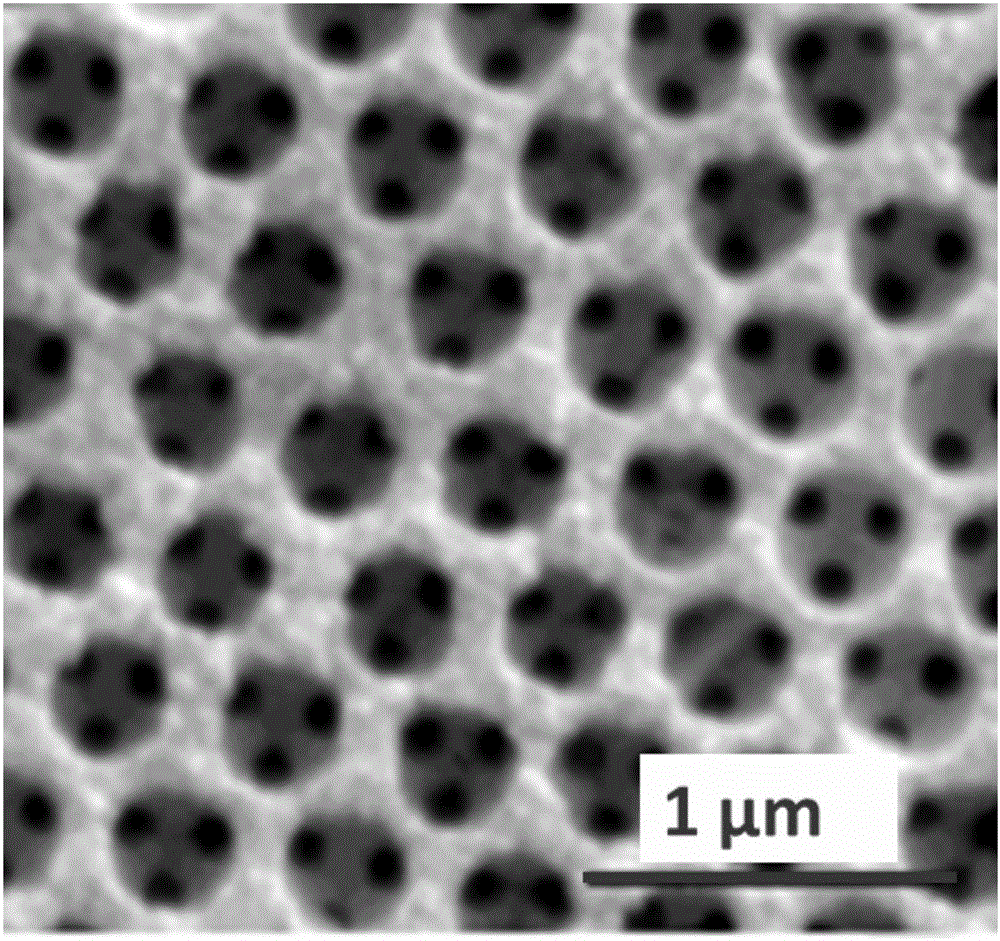

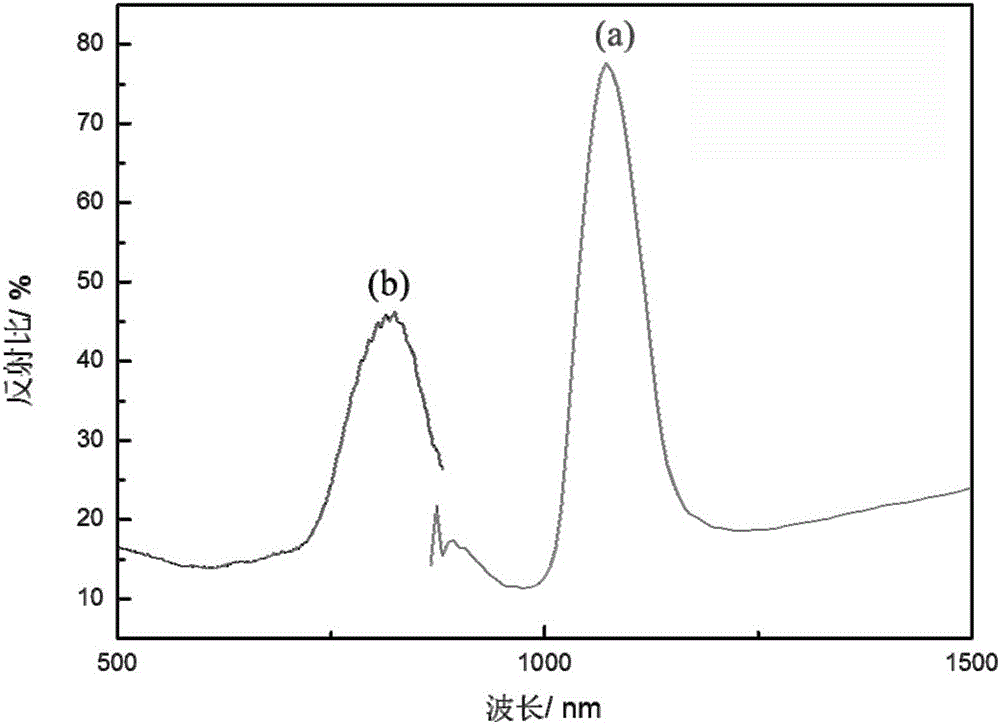

[0014] Specific implementation mode 1: In this implementation mode, the method for adjusting the bandgap of a three-dimensional photonic crystal by the lithiation method is implemented according to the following steps:

[0015] 1. Soak the copper foil in hydrochloric acid solution, then ultrasonically clean it with acetone, methanol and ultrapure water for 5 to 20 minutes to obtain the cleaned copper foil, and then use water as a solvent to configure a volume fraction of 0.1% to 0.3% Put the cleaned copper foil vertically into the PS microsphere emulsion, and incubate at a constant temperature of 50-70°C for 48-120 hours to obtain copper foil with PS colloidal templates;

[0016] Second, the ionic liquid (EMIM) TF 2 N (1-methyl-3-ethylimidazole bistrifluorosulfonic acid amine salt solvent) is put into glove box and carry out secondary distillation, in H 2 O and O 2 Under the condition that the content is less than 1ppm, the GeCl 4 Join (EMIM) TF 2 In N, dissolve and shake ...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment differs from Embodiment 1 in that in step 1, the copper foil is soaked in a hydrochloric acid solution with a volume concentration of 10% to 30% for 5 to 10 seconds. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that step three is in H 2 O and O 2 Under the condition that the contents are all less than 1ppm, germanium is electrodeposited in the electrolytic solution obtained in step 2 by a constant potential method. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com