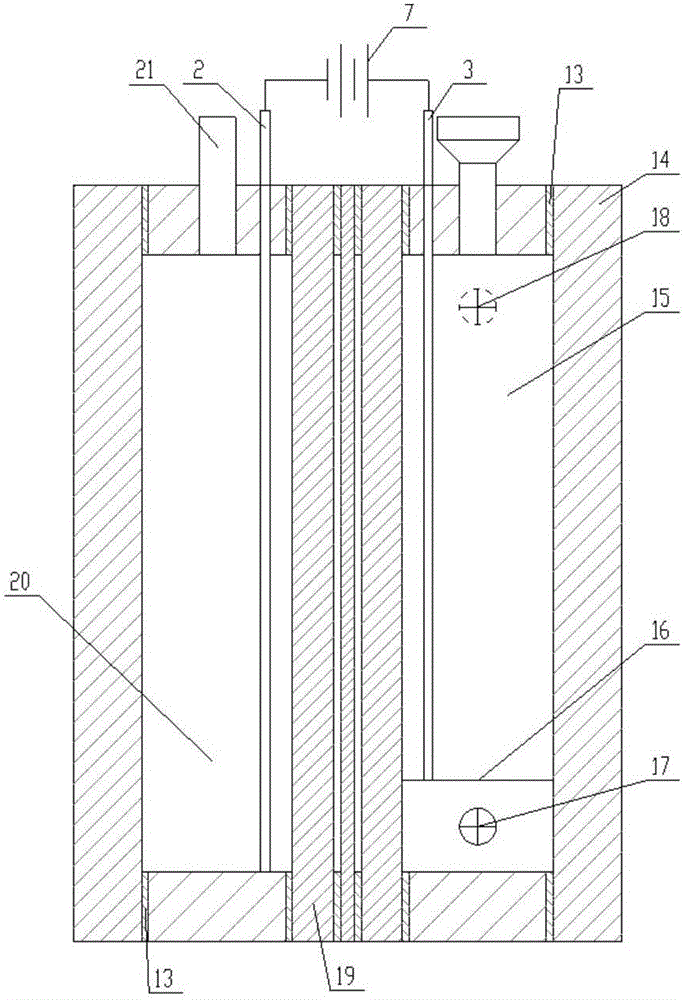

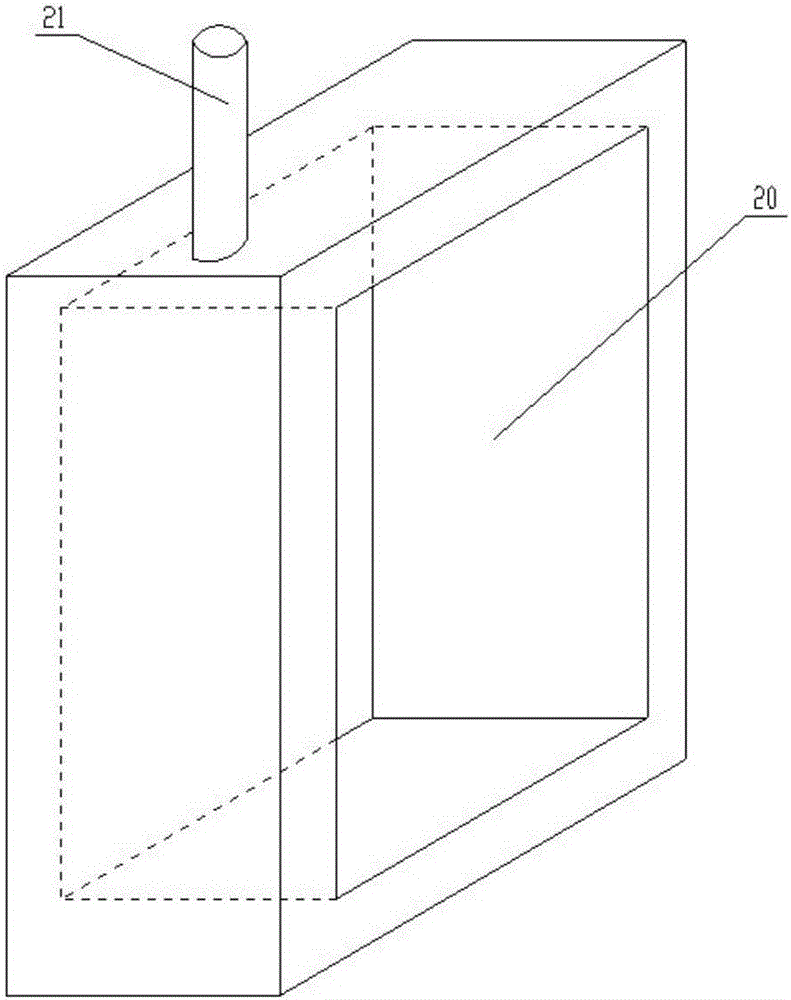

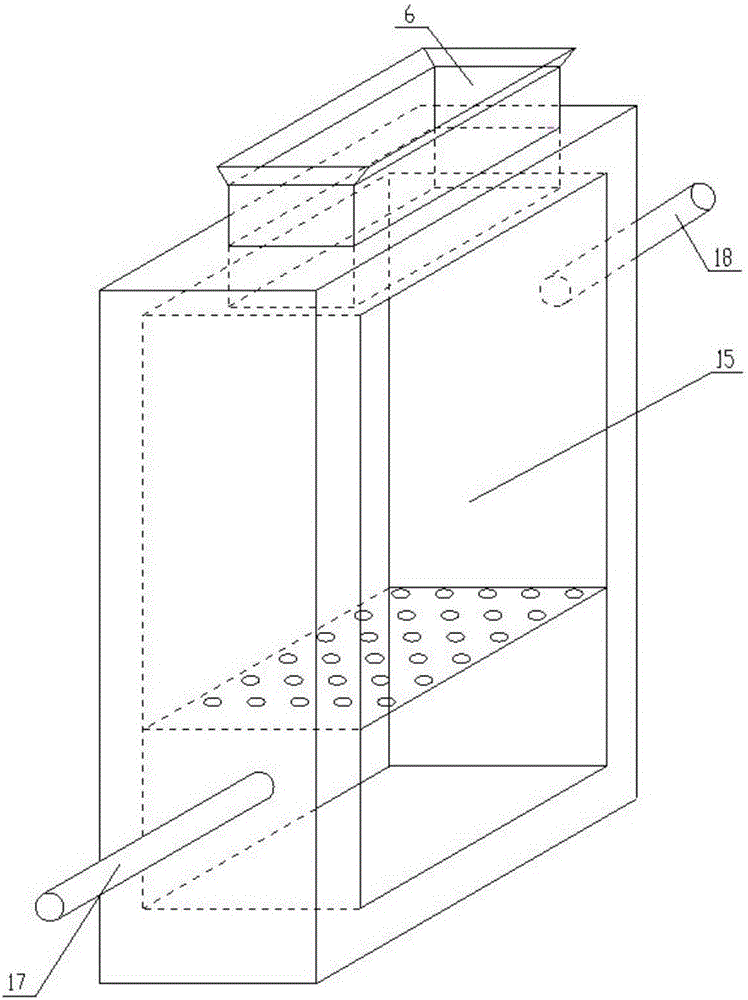

Electrolysis tin dissolving device, system and method for supplementing stannous ions in electrotinning solution

A technology of divalent tin ions and electroplating tin, applied in the field of metallurgy, can solve the problems of troublesome fixation of ion exchange membrane, unsuitable combination of multiple sets of cylindrical electrolytic cells, increase in cost, etc. The effect of reducing the loss of tin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] Adopt the electrolytic dissolving tin device of the present invention and technology thereof to carry out electrolytic dissolving tin, adopt U.S. DuPont N117CS type ion-exchange membrane, at 2A / dm 2 The data obtained from the experiment under the electrolytic current are shown in Table 1:

[0100] Table 1: The content of each component of electrolytic tin

[0101]

Embodiment 2

[0103] Adopt the electrolytic tin dissolving device of the present invention and its technique to carry out electrolytic tin dissolving, adopt Japanese Asahi Glass HSF type hydrogen ion selective permeation membrane, at 2A / dm 2 The data obtained from the experiment under the electrolytic current are shown in Table 2:

[0104] Table 2: The content of each component of electrolytic tin

[0105]

Embodiment 3

[0107] Adopt the electrolytic dissolving tin device of the present invention and technology thereof to carry out electrolytic dissolving tin, adopt the domestic Kerun membrane Nepem4110 type ion exchange membrane, at 2A / dm 2 The data obtained from the experiment under the electrolytic current are shown in Table 3:

[0108] Table 3: The content of each component of electrolytic tin

[0109]

[0110] It can be known from Examples 1, 2, and 3: at 2A / dm 2 When the three kinds of ion exchange membranes are used for electrolysis under the current density, the loss rate of tin is lower than 10%, which reduces the loss of tin and further reduces the production cost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com