Antibacterial plastic material and preparation method thereof

A technology of antibacterial plastics and raw materials, applied in the field of antibacterial plastics and its preparation, can solve the problems of high human toxicity, environmental pollution, poor temperature resistance, etc., and achieve the effect of small particle size, wide application and strong antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

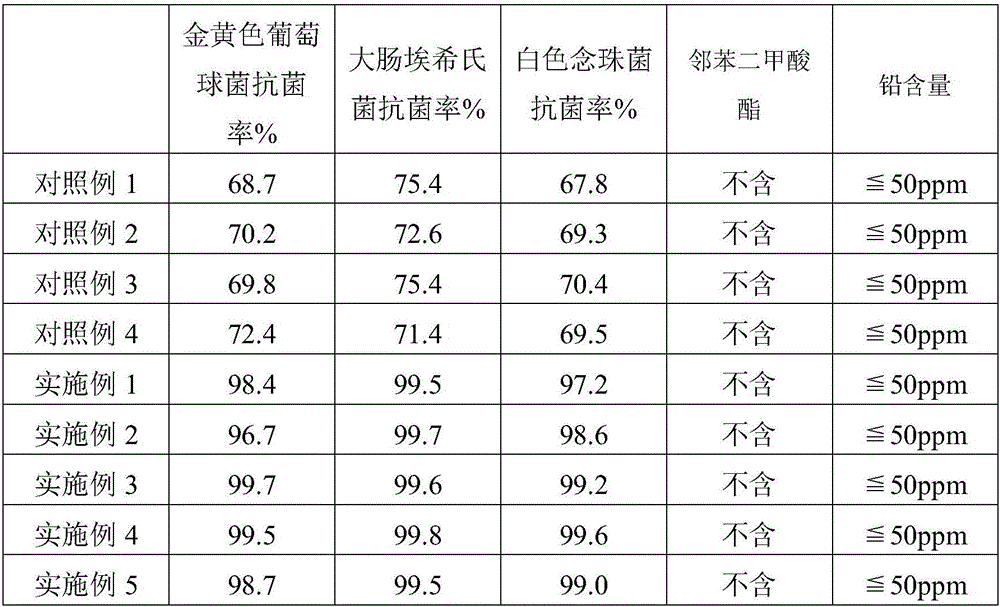

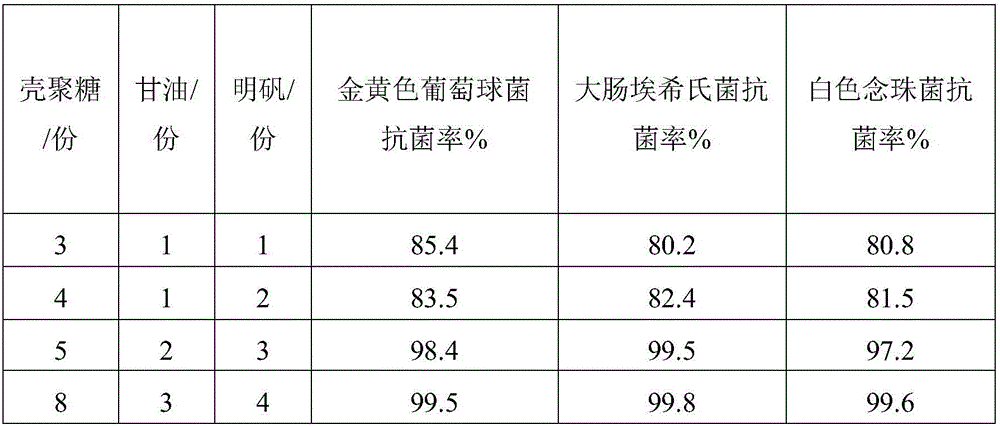

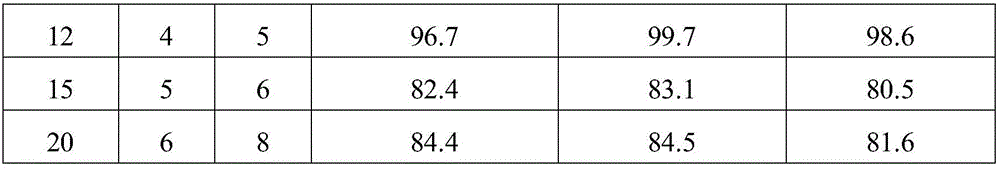

Examples

Embodiment 1

[0016] An antibacterial plastic with the following components:

[0017] 25 parts of high-density polyethylene, 10 parts of hydroxyapatite, 5 parts of chitosan, 4 parts of ammonium dihydrogen phosphate, 20 parts of ABS resin, 1681 parts of antioxidant, 2 parts of glycerin, 3 parts of alum.

[0018] Preparation:

[0019] (1) Weigh high-density polyethylene, hydroxycrystalline apatite, ammonium dihydrogen phosphate, ABS resin, and alum according to parts by weight, mix them evenly, and pass through a 100-mesh sieve;

[0020] (2) Stir the mixed material in a high-speed mixer at 120°C for 15 minutes, add chitosan, antioxidant, glycerin and water 1.5 times the weight of the mixed material during stirring;

[0021] (3) The agitated material is passed through a 150-mesh sieve and then sent to a twin-screw extruder to be extruded, pelletized and cooled to make antibacterial plastic.

Embodiment 2

[0023] An antibacterial plastic with the following components:

[0024] 38 parts of high-density polyethylene, 15 parts of hydroxycrystalline apatite, 12 parts of chitosan, 7 parts of ammonium dihydrogen phosphate, 32 parts of ABS resin, 164 parts of antioxidant, 4 parts of glycerin, 5 parts of alum.

[0025] Preparation:

[0026] (1) Weigh high-density polyethylene, hydroxycrystalline apatite, ammonium dihydrogen phosphate, ABS resin, and alum according to parts by weight, mix them evenly, and pass through a 150-mesh sieve;

[0027] (2) Stir the mixed material in a high-speed mixer at 150°C for 10 minutes, and add chitosan, antioxidant, glycerin and water twice the weight of the mixed material during stirring;

[0028] (3) The agitated material is passed through a 200-mesh sieve and then sent to a twin-screw extruder for extrusion, pelletized and cooled to make antibacterial plastic.

Embodiment 3

[0030] An antibacterial plastic with the following components:

[0031] 32 parts of high density polyethylene, 13 parts of hydroxyapatite, 9 parts of chitosan, 5 parts of ammonium dihydrogen phosphate, 26 parts of ABS resin, 1682 parts of antioxidant, 3 parts of glycerin, 4 parts of alum.

[0032] Preparation:

[0033] (1) Weigh high-density polyethylene, hydroxycrystalline apatite, ammonium dihydrogen phosphate, ABS resin, and alum in parts by weight, mix them evenly, and pass through a 125 mesh sieve;

[0034] (2) Stir the mixed material in a high-speed mixer at 135°C for 13 minutes, add chitosan, antioxidant, glycerin and an appropriate amount of water 1.8 times the weight of the mixed material during stirring;

[0035] (3) The agitated material is passed through a 175-mesh sieve and then sent to a twin-screw extruder for extrusion, pelletized and cooled to make antibacterial plastic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com