Thermally-expandable solid epoxy resin microcellular foam material and preparation method thereof

A technology of microcellular foaming material and solid epoxy resin, which is applied in the field of solid epoxy resin microcellular foaming material and its preparation, and epoxy resin microcellular foaming material, and can solve the problem of large cell size of solid thermally expandable material. , difficult to form processing, inconvenient storage and other problems, to achieve the effect of good physical and mechanical properties, easy processing, convenient storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take solid powder epoxy composition (40 parts of solid bisphenol A epoxy resin, 20 parts of melamine epoxy resin, 40 parts of anhydride curing agent, 10 parts of nano-montmorillonite, 10 parts of nano-carboxy nitrile glue, N, N' -Dinitrosopentamethylenetetramine 0.6 parts) 35g, compacted at 15MPa, put into a mold with 25% of the foaming space and foam at 110°C, after 4h, raise the oven temperature to 180°C , after 3 hours of heat preservation, naturally cool to room temperature and release the mold to obtain a thermally expandable solid microporous foam material; put the thermally expandable solid material into a 90-degree oven to expand by itself. Setting the mold to have different foaming spaces can prepare thermally expandable solid microcellular foaming materials of different densities, and can also adjust the thermal expansion rate of the material.

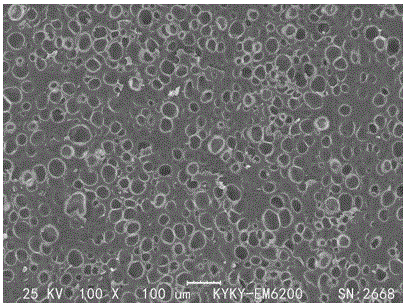

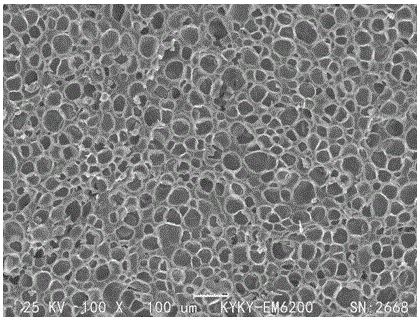

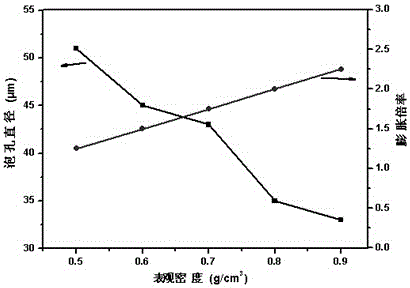

[0022] Experimental results: if Figure 1~Figure 2 As shown, after thermal expansion of the heat-expandable solid m...

Embodiment 2

[0025] Get the solid powder epoxy composition (40 parts of solid bisphenol A epoxy resin, 20 parts of solid novolak epoxy resin, 40 parts of anhydride curing agent, 7 parts of nano calcium carbonate, 8 parts of micron nitrile glue, 5 parts of carbon fiber, even Nitrogendiformamide 1.2 parts) 35g, compacted at 15MPa, put into a mold with 10% of the foaming space and foam at 150°C, after 1h, raise the oven temperature to 180°C, keep warm for 3h and then cool naturally to The heat-expandable solid microporous foam material is obtained by demoulding at room temperature; the heat-expandable solid material can be self-expanded in an oven at 110 degrees.

[0026] After testing, the cell diameter and apparent density of the microcellular foamed material prepared in this example before expansion are 30 μm and 1.1 g / cm 3 , the cell diameter and apparent density of the expanded material are 48 μm and 0.3 g / cm respectively 3 .

Embodiment 3

[0028] Get the solid powder epoxy composition (50 parts of solid bisphenol A epoxy resin, 10 parts of solid aliphatic epoxy resin, 40 parts of p-phenylenediamine, 3 parts of zinc oxide, 10 parts of nano carboxylated nitrile glue, short glass fiber 7 parts, sodium bicarbonate 2.4 parts) 35g, compacted at 15MPa, placed in a mold with a foaming space of 10% and foamed at 150°C, after 1h, raise the oven temperature to 180°C, keep warm for 3h and then naturally Cool to room temperature and demould to obtain a heat-expandable solid microporous foam material; put the heat-expandable solid material into a 90-degree oven to expand by itself.

[0029] After testing, the cell diameter and apparent density of the microcellular foamed material prepared in this example before expansion are 30 μm and 1.1 g / cm 3 , the cell diameter and apparent density of the expanded material are 82 μm and 0.16 g / cm respectively 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Cell diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com