Staged air supplying and heating device and method for combustion chamber of coke furnace

A heating device and combustion chamber technology, used in the heating of coke ovens, coke ovens, combustible gas heating coke ovens, etc., can solve the problem of high concentration of nitrogen oxides, and achieve the effects of optimizing combustion conditions, reducing concentration and improving combustion state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

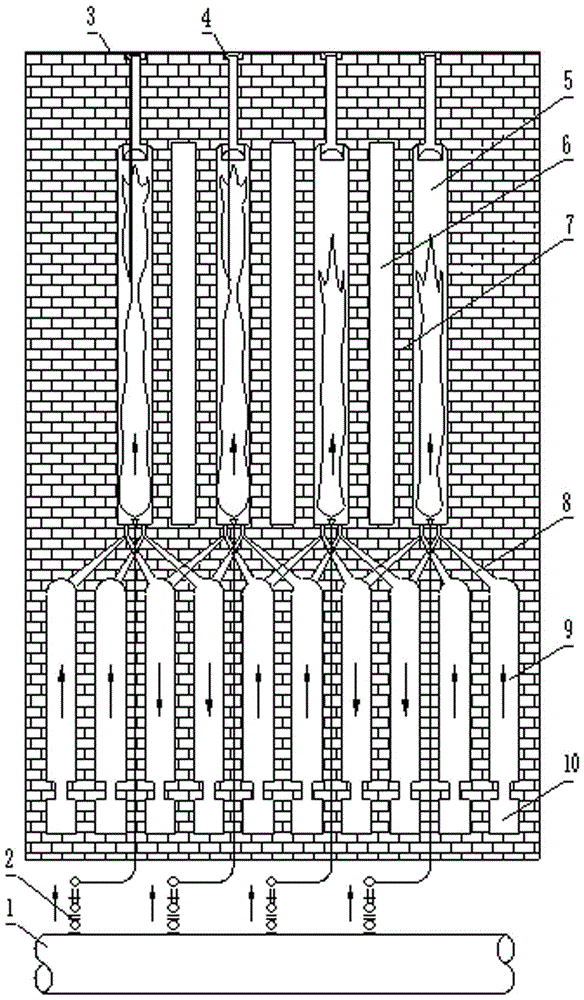

[0026] Such as figure 1 A coke oven combustion chamber sectional air supply heating device shown, including an automatic heating and temperature adjustment system, an oxygen-enriched air secondary air supply air distribution system, and an oxygen-enriched air air supply pipeline system;

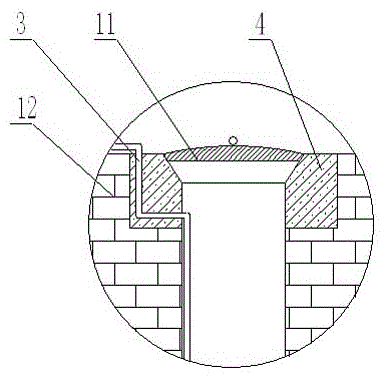

[0027] The oxygen-enriched air secondary air supply air distribution system described therein includes a secondary air pipeline 3 communicated with the oxygen-enriched production equipment through a blower, and the secondary air pipeline 3 passes through the combustion chamber from the top of the combustion chamber 5 5, the end is located at the middle and upper part of the combustion chamber 5;

[0028] The oxygen-enriched air supply pipeline system is an oblique air pipe 8 connecting the bottom of the combustion chamber 5 and the top of the regenerator 9, and the bottom of the regenerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com