A method for recovering the solvent in the solid residue in the heavy oil solvent extraction process

A technology for solid residue and heavy oil, which is used in solid separation, petroleum industry, processing of hydrocarbon oil, etc., can solve the problem of inability to discharge directly, and achieve the effect of reducing sewage discharge, simple operation and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

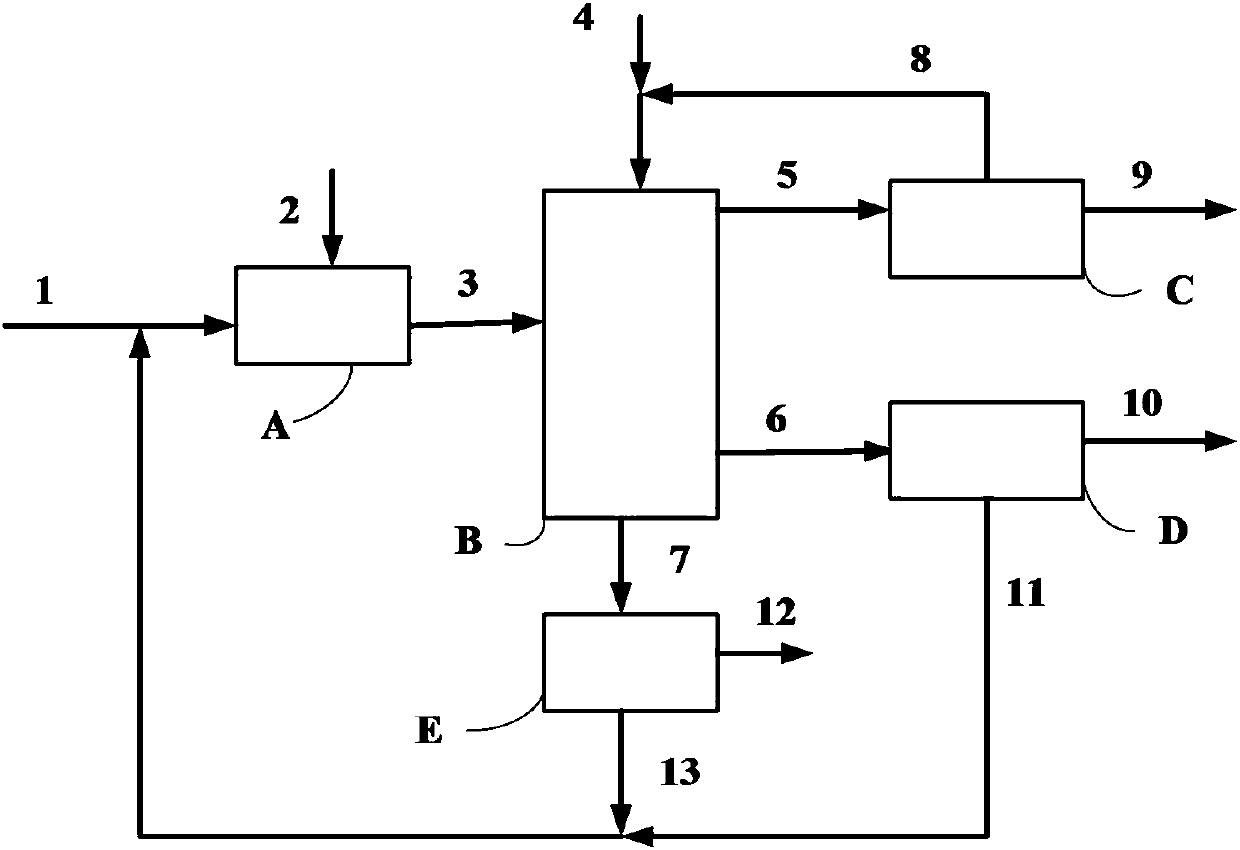

[0048] A method for reclaiming the solvent in the solid residue in the heavy oil solvent extraction process, the steps are as follows:

[0049] ⑴Using 20g of solid residue obtained by extracting oil sand with toluene (the solvent content is 10.2%, and the residual oil content is 2%), mix it with 20mL aqueous solution to make a slurry, put it in the pulping device A and mix it, and transport the mixed slurry to the flotation device In device B, carbon dioxide gas is passed into the mixed slurry at a speed of 1.5 L / min, and the diameter of the bubbles is less than 2 mm under the condition of stirring, and flotation is carried out for 1 hour.

[0050] (2) The gas mixture obtained by flotation is exported to the solvent recovery device C for cooling and desolvation treatment at 0°C, and the solvent is recovered, and the obtained desolvated gas is recycled to the flotation device B for use.

[0051] (3) The oil-water foam floating on the upper layer of the flotation device B is rec...

Embodiment 2

[0055] A method for reclaiming the solvent in the solid residue in the heavy oil solvent extraction process, the steps are as follows:

[0056] (1) Use n-heptane to extract 20g of the solid residue obtained from the oil sand (the solvent content is 10.2%, and the residual oil content is 5%), mix it with 20ml of aqueous solution to make a slurry, put it in the pulping device A for mixing, and transport the mixed slurry to the buoy In the filter device B, feed carbon dioxide gas into the mixed slurry at a speed of 1.5L / min, and the bubble diameter is less than 2mm under the situation of stirring, and carry out flotation for 1 hour (stirring speed 180r / min).

[0057] (2) The gas mixture obtained by flotation is exported to the solvent recovery device C for cooling and desolvation treatment at 0°C, and the solvent is recovered, and the obtained desolvated gas is recycled to the flotation device B for use.

[0058] (3) The oil-water foam floating on the upper layer of the flotation...

Embodiment 3

[0062] A method for reclaiming the solvent in the solid residue in the heavy oil solvent extraction process, the steps are as follows:

[0063] (1) 20g of solid residue obtained by extracting oil sands with naphtha (the solvent content is 12.6%, and the residual oil content is 4.9%) is mixed with 20ml of aqueous solution to make a slurry, which is placed in the pulping device A for mixing, and the mixed slurry is transported to the buoy In the filter device B, carbon dioxide gas is passed into the mixed slurry at a speed of 5 L / min, and the diameter of the bubbles is less than 1 mm under the condition of stirring, and the flotation is carried out for 1 hour.

[0064] (2) The gas mixture obtained by flotation is exported to the solvent recovery device C for cooling and desolvation treatment at 0°C, and the solvent is recovered, and the obtained desolvated gas is recycled to the flotation device B for use.

[0065] (3) The oil-water foam floating on the upper layer of the flotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com