Coal direct liquefying and circulating solvent and preparation method thereof

A technology of direct coal liquefaction and coal direct liquefaction of oil, which is applied in the field of coal chemical industry, can solve the problems of high hydrogen consumption and poor hydrogen supply performance, and achieve the effects of reducing volume, improving hydrogen supply performance and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

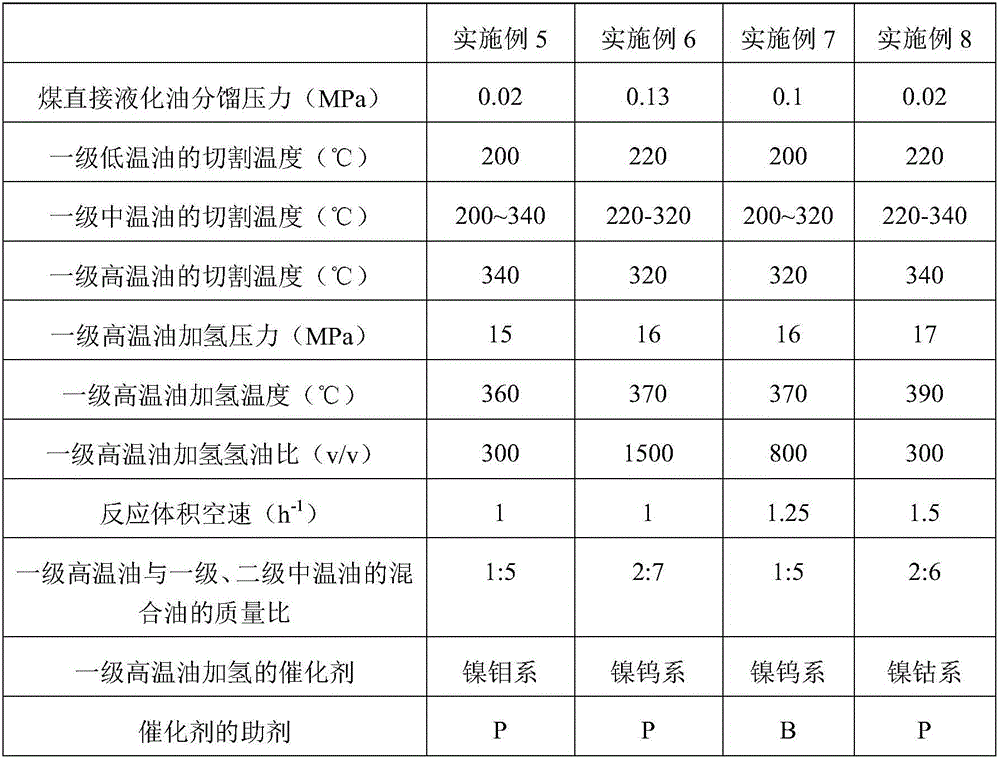

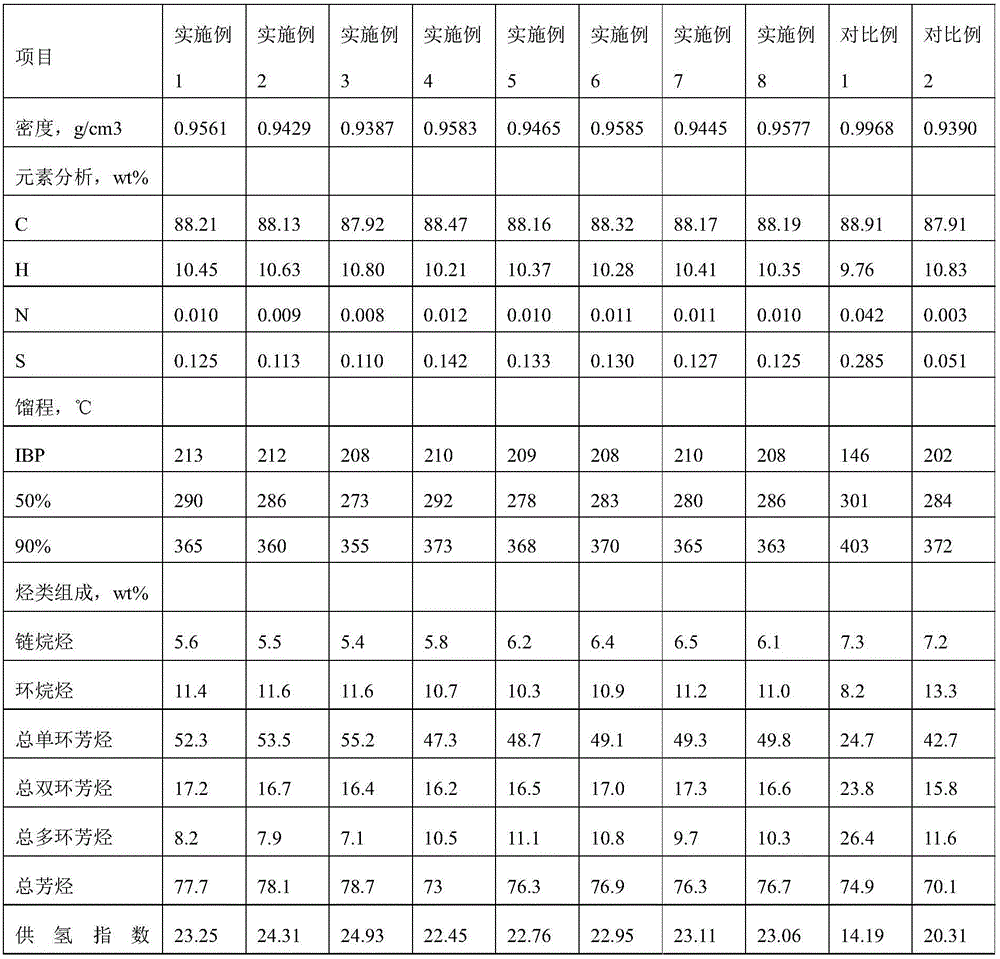

[0024] According to a typical embodiment of the present invention, a method for preparing a circulating solvent for direct coal liquefaction is provided. The preparation method comprises the following steps: S1, performing fractional distillation on the direct coal liquefaction oil under the condition of a pressure of 0.02-0.2 MPa to obtain the first-grade low-temperature oil, the first-grade medium-temperature oil and the first-grade high-temperature oil; S2, the first-grade high-temperature oil Perform hydrogenation and fractionation to obtain secondary low-temperature oil, secondary medium-temperature oil, and secondary high-temperature oil; S3, mix all secondary high-temperature oil with part of the first-level medium-temperature oil and secondary medium-temperature oil to obtain coal directly Liquefied circulating solvent, wherein, the distillation range of the first-grade low-temperature oil and the second-grade low-temperature oil is 320°C.

[0025] In the present inven...

Embodiment 1

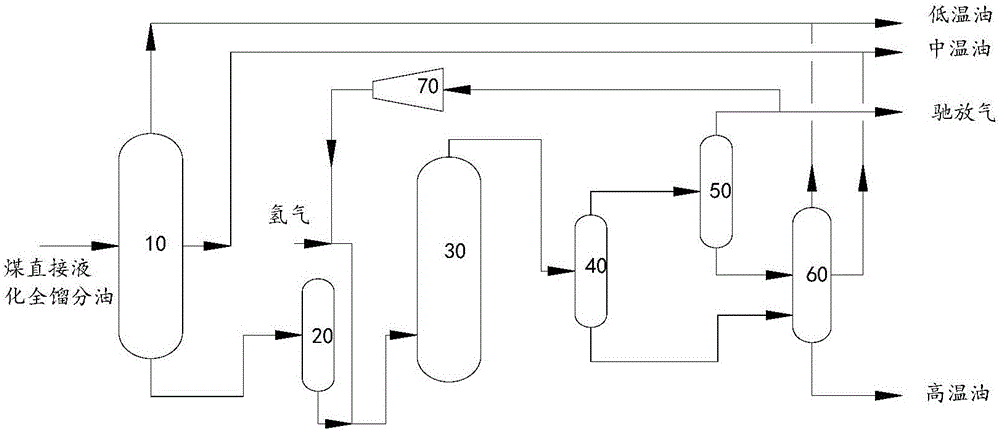

[0035] Such as figure 1 As shown, in this embodiment, the preparation device for direct coal liquefaction circulating solvent consists of a fractionation tower 10, a buffer tank 20, a hydrogenation reactor 30, a high temperature separator 40, a low temperature separator 50, a fractionation tower 60 and a hydrogen circulation compressor 70 composition.

[0036] The coal direct liquefaction full distillate oil from the coal direct liquefaction unit, that is, the coal direct liquefaction oil, enters the fractionation tower 10 and is cut into three fractions: first-grade low-temperature oil, first-grade medium-temperature oil and first-grade high-temperature oil. Among them, the primary high-temperature oil enters the buffer tank 20 as a raw material for subsequent hydrogenation. The secondary high-temperature oil from the bottom of the buffer tank 20 is mixed with hydrogen and enters the hydrogenation reactor 30 for hydrogenation reaction. The hydrogenated product from the hydr...

Embodiment 2

[0044] With other conditions unchanged, change the reaction temperature of the ebullated bed hydrogenation reactor to 400°C, and the reaction space velocity to 1h -1 Hydrogenation stabilization is carried out under certain conditions to obtain hydrogenation-stabilized oil. The obtained high-temperature oil and part of the medium-temperature oil are prepared according to the ratio of 2:7 to make the coal direct liquefaction circulating solvent.

[0045] The hydrogenation catalyst used in the present invention is the same as embodiment 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com