Physical vapor deposition technology applied to communication system assembly for replacing water electroplating

A technology of physical vapor deposition and communication system, which is applied in the field of physical vapor deposition (PVD for short), can solve problems such as no breakthroughs, and achieve the effects of less harmful substances, standardized process flow, and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

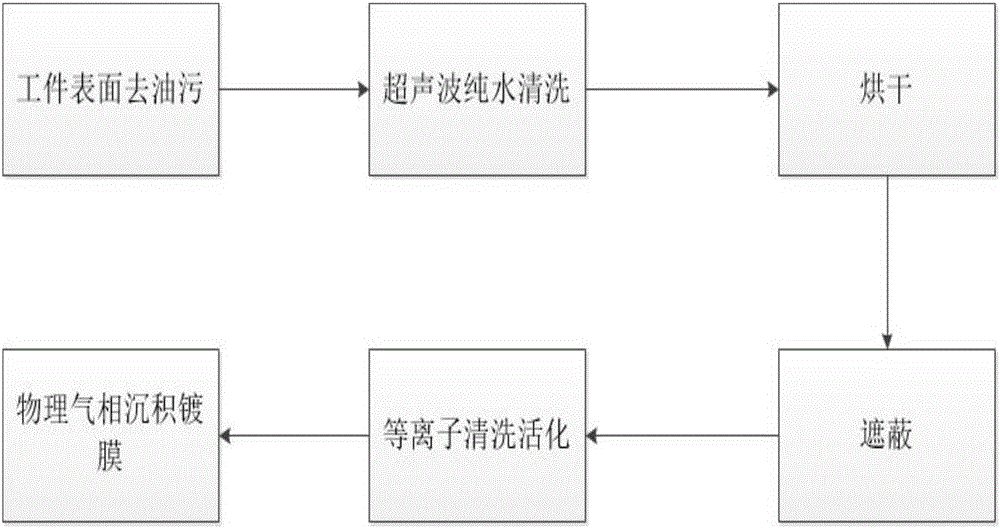

Image

Examples

Embodiment 1

[0036] Embodiment 1: In this embodiment, copper film and silver film are sequentially plated on the filter base material of cast aluminum as an example, and the physical vapor deposition process applied to communication system components instead of water electroplating provided by the present invention is explained as follows:

[0037] Concrete process steps are as follows:

[0038] 1) Degreasing the surface of the workpiece

[0039] Environmentally friendly degreasing liquid degreasing treatment, the temperature of the degreasing liquid is 60°C, and the treatment time is 20 minutes. After degreasing, rinse with tap water;

[0040] 2) Ultrasonic pure water washing

[0041] Contains the following two steps in sequence:

[0042] 1) Ultrasonic cleaning with pure water for 15 minutes at room temperature;

[0043] 2) Ultrasonic cleaning with pure water for 15 minutes at 50°C.

[0044] 3) drying

[0045] The workpiece is dried in an oven at a temperature of 110°C for 30 minutes...

Embodiment 2

[0055] Embodiment 2: In this embodiment, taking copper film and silver film sequentially plated on a machined filter cover plate as an example, the physical vapor deposition coating process applied to communication system components that replaces water electroplating provided by the present invention is explained as follows :

[0056] Concrete process steps are as follows:

[0057] 1) Degreasing the surface of the workpiece

[0058] Sandblasting or brushing treatment first, blown with compressed air, and then rinsed with tap water;

[0059] Then use environment-friendly degreasing liquid to degrease. The temperature of the degreasing liquid is 70°C, and the processing time is 15 minutes. After degreasing, rinse with tap water;

[0060] 2) Ultrasonic pure water washing

[0061] Contains the following two steps in sequence:

[0062] 1) Ultrasonic cleaning with pure water for 20 minutes at room temperature;

[0063] 2) Ultrasonic cleaning with pure water for 10 minutes at 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com