Self-adhesive PSA (polysulfonamide)/silicone rubber composite nanofiber porous membrane

A composite nanofiber and polysulfone aramid fiber technology, which is applied in adhesives, dispersed particle filtration, electrical components, etc., can solve problems such as increasing process difficulty, poor adhesion, and affecting product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

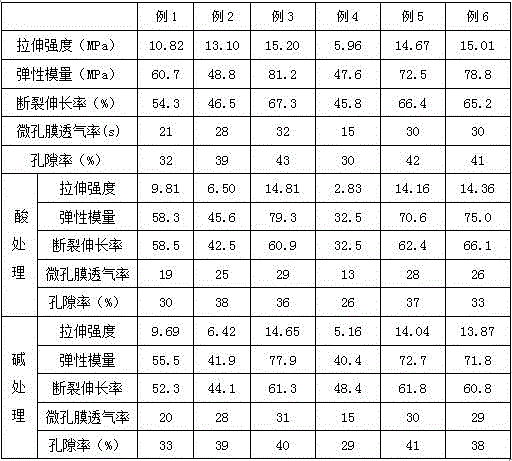

Examples

preparation example Construction

[0055] Another aspect of the present invention provides a kind of preparation method of self-adhesive polysulfone aramid fiber / silicone rubber composite nanofiber porous membrane, at least comprises the following steps:

[0056] Sample dissolution: dissolve silica gel in 3 times the volume of organic solvent A, and dissolve polysulfone aramid in 5 times the volume of organic solvent B by weight;

[0057] Electrospinning: Pour the solution in step (1) obliquely into an electrospinning machine for electrospinning to form an electrospun polysulfone aramid / silicone rubber composite nanofiber porous membrane;

[0058] Thermal bonding: Thermal bonding of polysulfone aramid fiber and silicone rubber at 80-180°C to form a self-adhesive nanofiber porous membrane between fibers;

[0059] Wherein, A solvent is at least one of ethyl acetate, toluene, xylene, and acetone; B solvent is at least one of DMAC, DMF, and DMSO.

[0060] In one embodiment, the thermal bonding temperature is 90-16...

Embodiment 1

[0081] A self-adhesive polysulfone aramid fiber / silicone rubber composite nanofiber porous membrane, the mass ratio of polysulfone aramid fiber to silicon rubber is 1.25:1, and its preparation method comprises the following steps:

[0082] (1) Sample dissolution: Dissolve 1g of 703 silicone rubber B1 in 30ml of organic solvent ethyl acetate, 10g of polysulfone aramid fiber A1 in 70ml of organic solvent DMAC, after mixing, stir evenly;

[0083] (2) Electrospinning: Pour the solution in step (1) obliquely into the electrospinning machine for electrospinning. The voltage during the electrospinning is 25kV, and the distance from the spinning nozzle to the opposite electrode collecting substrate is 20cm, spinning flow rate is 0.003mm / s; form electrospun polysulfone aramid fiber / 703 silicone rubber composite nanofiber porous membrane;

[0084] (3) Thermal bonding: Polysulfone aramid fiber and 703 silicone rubber were thermally bonded at 80°C for 15 minutes, and the solvent was remov...

Embodiment 2

[0086] A self-adhesive polysulfone aramid fiber / silicone rubber composite nanofiber porous membrane, the mass ratio of polysulfone aramid fiber to silicon rubber is 9:1, and its preparation method comprises the following steps:

[0087] (1) Sample dissolution: Dissolve 1g of 705 silicone rubber B3 in 30ml of organic solvent toluene, and 9g of polysulfone aramid fiber A2 in 70ml of organic solvent DMF. After mixing, stir evenly;

[0088] (2) Electrospinning: Pour the solution in step (1) obliquely into the electrospinning machine for electrospinning. The voltage during the electrospinning is 25kV, and the distance from the spinning nozzle to the opposite electrode collecting substrate is 20cm, spinning flow rate is 0.003mm / s; form electrospun polysulfone aramid fiber / 705 silicone rubber composite nanofiber porous membrane;

[0089] (3) Thermal bonding: Polysulfone aramid fiber and 705 silicone rubber were thermally bonded at 180°C for 15 minutes, and the solvent was removed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com