Heat-preservation and sound-insulation wall

A sound insulation and wall technology, applied to walls, buildings, building components, etc., can solve the problems of thermal insulation and sound insulation wall weight, difficult construction, inconvenient construction, etc., to achieve convenient construction and transportation, easy operation, and easy construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

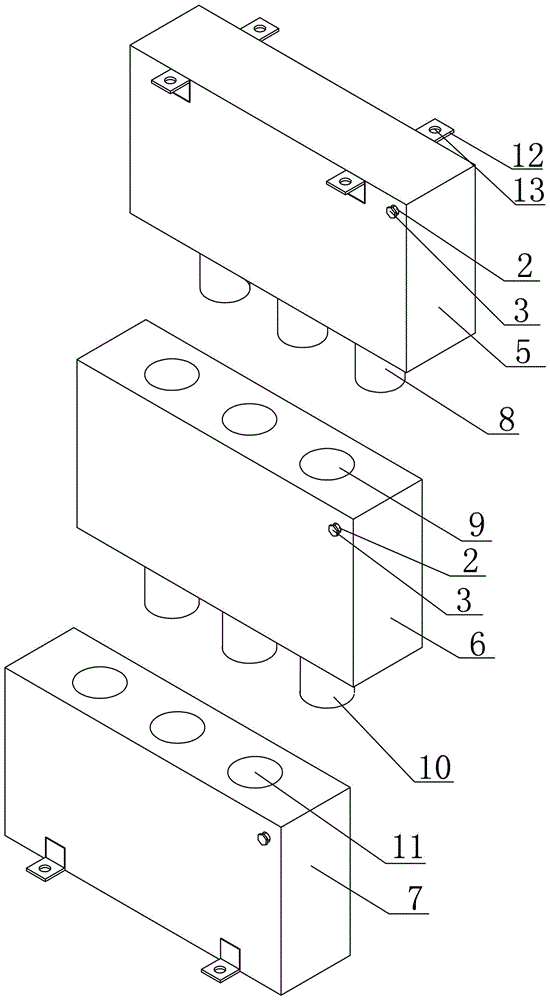

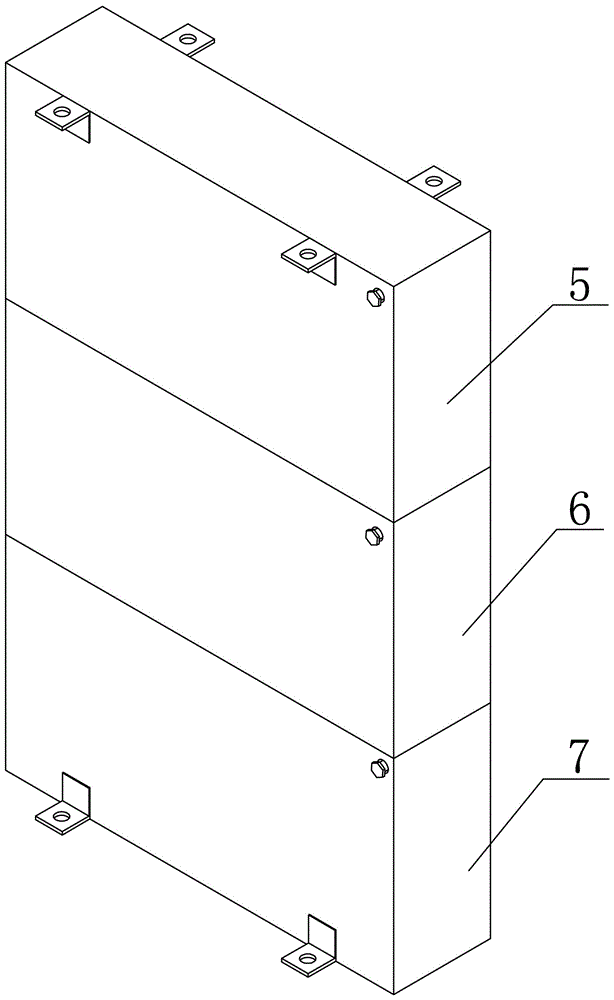

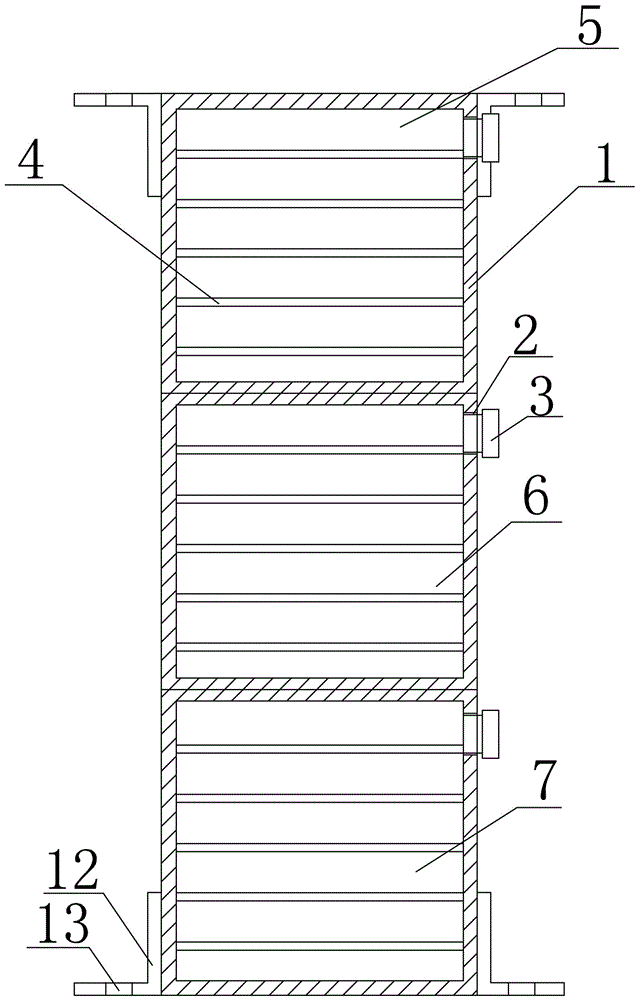

[0030] Such as figure 1 , figure 2 and image 3 As shown, a thermal insulation and sound insulation wall includes a wall body, and the wall body is composed of 3 interconnected hollow cube structures. The 3 hollow cube structures are stacked horizontally. The middle wall 6 and the lower wall 7, the upper wall 5, the middle wall 6 and the lower wall 7 are all hollow cubic structures formed by interconnecting panels 1, wherein the panels 1 are made of high-carbon steel plates. The thickness of the middle panel 1 is 6mm, which can be 7mm, 7.5mm or 8mm in actual use. The valve 2 is set on the upper wall 5, the middle wall 6 and the lower wall 7, and the valve 2 is set to match the valve 2. The valve cap 3, the bottom of the upper wall 5 is evenly provided with a plurality of first protrusions 8, the number of the first protrusions 8 in this embodiment is 3, and the middle wall 6 is provided with a matching first protrusion 8 The first groove 9, the bottom of the middle wall bo...

Embodiment 2

[0035] The structure of the wall body in embodiment 2 is basically the same as that in embodiment 1, the difference is that the wall body is made up of a plurality of interconnected hollow cube structures 14, and the structure of each hollow cube body is the same as that of the upper wall body and the middle wall body in embodiment 1. Similar to the lower wall structure, each hollow cubic structure 14 is formed by connecting multiple panels, wherein the panel is a high-carbon steel plate, and the thickness of the panel in this embodiment is 7mm; each hollow cubic structure 14 is provided with a valve , each valve is provided with a valve cap 3 that matches the valve, and each hollow cubic structure 14 is provided with the same structure and the same distribution of support columns as in Embodiment 1, wherein the diameter of the support columns in this embodiment is 5mm, and the support columns The distance between them is 11mm, and the thickness of the wall is 100mm. The conne...

Embodiment 3

[0040] This embodiment has the same structure as the thermal insulation and sound insulation wall in Example 1, and the formula of the thermal insulation and sound insulation coating has been adjusted. The difference is that the thermal insulation and sound insulation coating includes the following raw materials in parts by weight: 34 parts of styrene-acrylic emulsion, 8 parts of nitrile rubber, 7.5 parts of silica sol, nano-SiO 2 3 parts, 5 parts of vermiculite powder, 3 parts of zinc borate, Al(OH) 3 2 parts, 1.2 parts of ethylene glycol, 1.2 parts of emulsifier, 7 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com