Method for strengthening flow conductivity of hydraulic fracture of soft coal bed

A technology of hydraulic fractures and flow conductivity, applied in the direction of microorganism-based methods, biochemical equipment and methods, and mining fluids, can solve problems such as poor drainage effects, loose coal quality, and low mechanical strength of coal bodies, and achieve improved Effects of mechanical strength, reduced clogging, and technical ease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

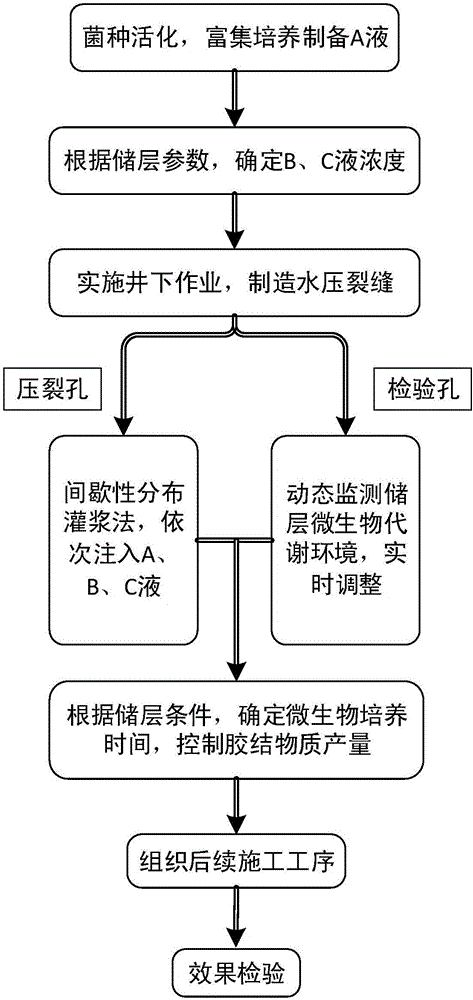

Method used

Image

Examples

Embodiment 1

[0030] Use distilled water to prepare the medium required for proliferation culture. The components and concentrations of the medium are peptone 5.0g / L, meat extract 3.0g / L, urea 20.0g / L, MnSO 4 ·H 2 O 10mg / L, the prepared culture medium was sterilized by high-temperature steam at 121°C for 20 minutes, and then placed in a sterile operating table to cool for later use. The purchased strains are in the state of freeze-dried powder, which are stored in vacuum in the ampoule, break the ampoule, inoculate the freeze-dried powder into a triangular flask containing 10mL medium for cultivation, place the triangular flask in the incubator, and transfer it to the triangular flask The formation of bacterial colonies in it indicates that the activation is successful. Inoculate the activated bacterial solution into a Erlenmeyer flask containing 100 mL of medium for proliferation and culture.

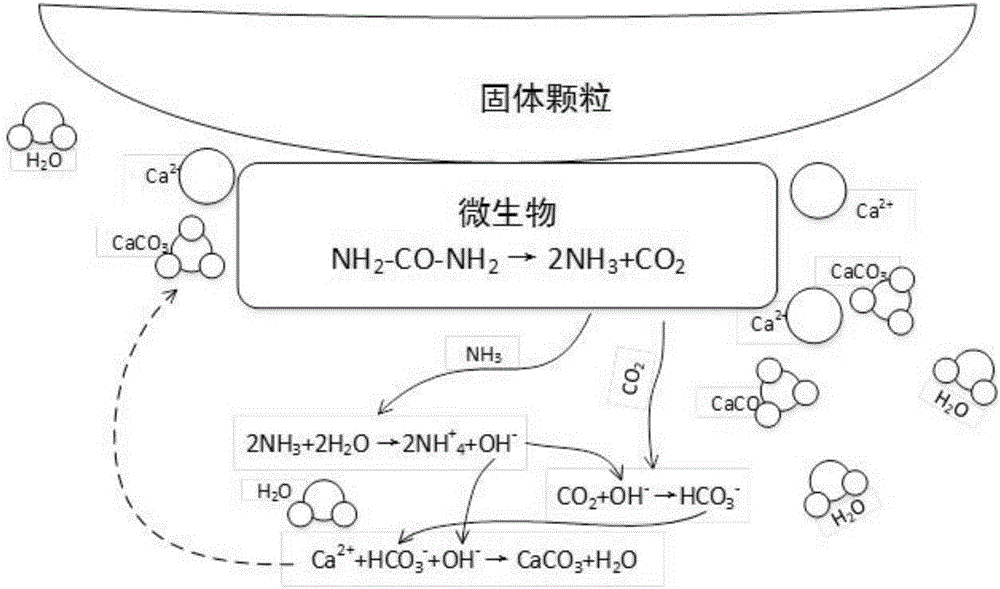

[0031] Prepare fixative and gelling solution, the fixative is 0.05mol / L CaCl 2 Solution, gel s...

Embodiment 2

[0037] Example 2 differs from Example 1 in that: (1) the concentration of the fixative solution is 0.06 mol / L, and the concentration of the gelling solution is 1.0 mol / L; (2) the pH of the reservoir mixed solution is 9.0, and the DO value is 3 mg / L , the reservoir temperature is 35°C; (3) The process of injecting the gelling solution is intermittent twice.

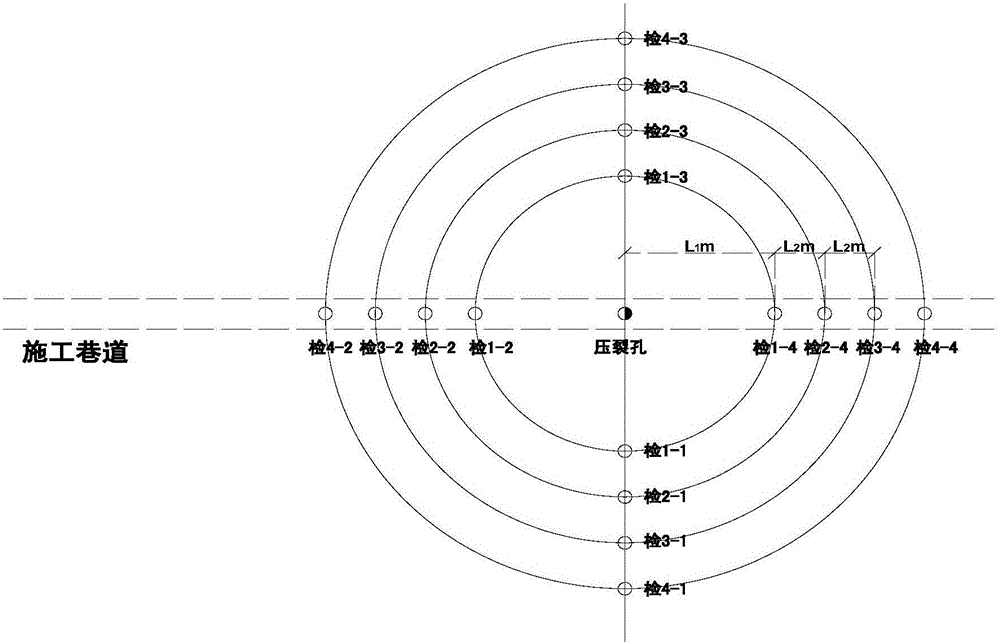

[0038] After the reservoir stimulation is completed, check the gas content, extraction concentration, flow rate and permeability coefficient through the inspection holes of the direction and tendency of the coalbed methane reservoir.

Embodiment 3

[0040] Embodiment 3 differs from Example 1 in that: (1) medium components and concentrations are respectively peptone 5.5g / L, meat extract 3.5g / L, urea 22g / L, MnSO 4 ·H 2 O 8~12mg / L; (2) The injection speed of the fixative was 18L / min, and the injection speed of the gelling solution was 1.5L / min. After the injection of the gelling solution, there was an interval of 24 hours. The whole injection process was intermittent for 6 times.

[0041] After the reservoir stimulation is completed, check the gas content, extraction concentration, flow rate and permeability coefficient through the inspection holes of the direction and tendency of the coalbed methane reservoir.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com