Surrounding rock consolidation system for reducing rock burst hazards

A surrounding rock and rockburst technology, which is applied in the field of surrounding rock reinforcement in deep underground rock mass engineering, can solve the problems of high density, high reinforcement cost, and difficult on-site operation, so as to achieve easy suspension, increase the strength of surrounding rock, and reduce rockburst The effect of the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

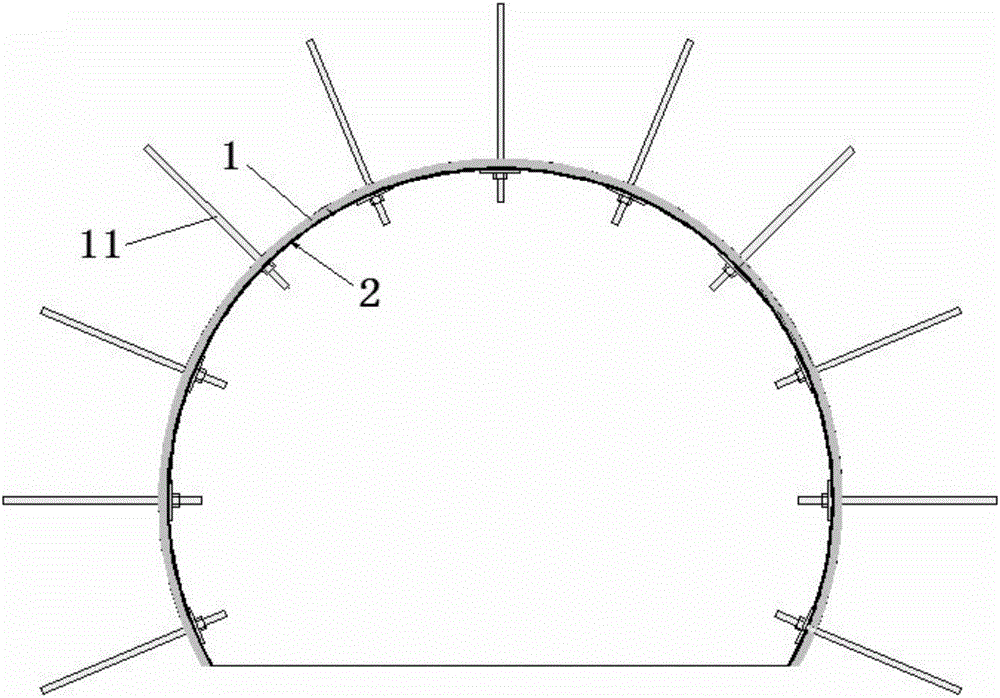

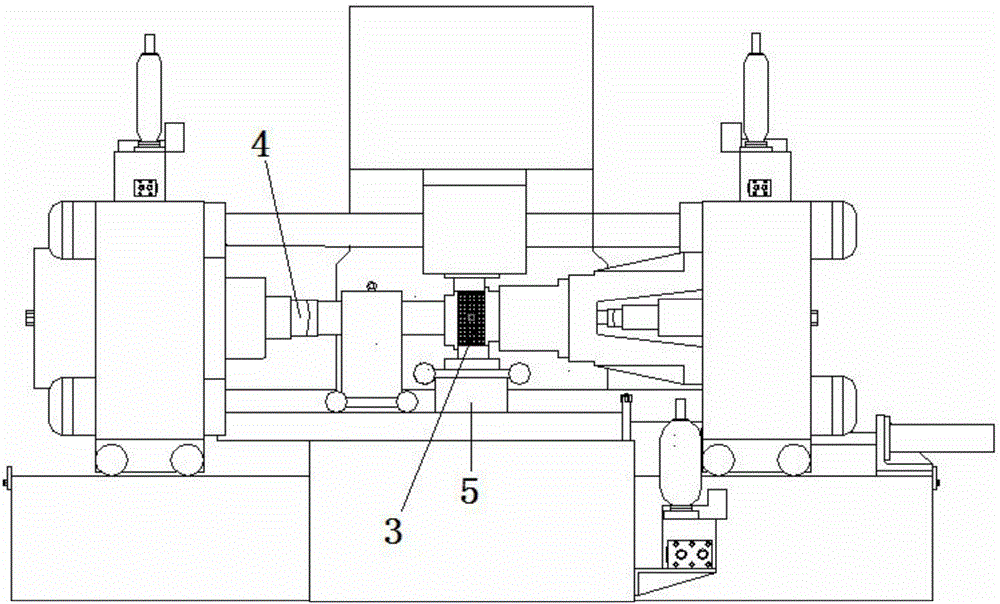

[0031] In order to make the purpose of the present invention and the technical solution clearer, the technical solution of the present invention will be clearly and clearly described below in conjunction with an implementation example in the accompanying drawings of the description and an indoor rockburst test of a basalt fiber cloth and a rock bolt jointly supporting a rock sample. Describe it completely.

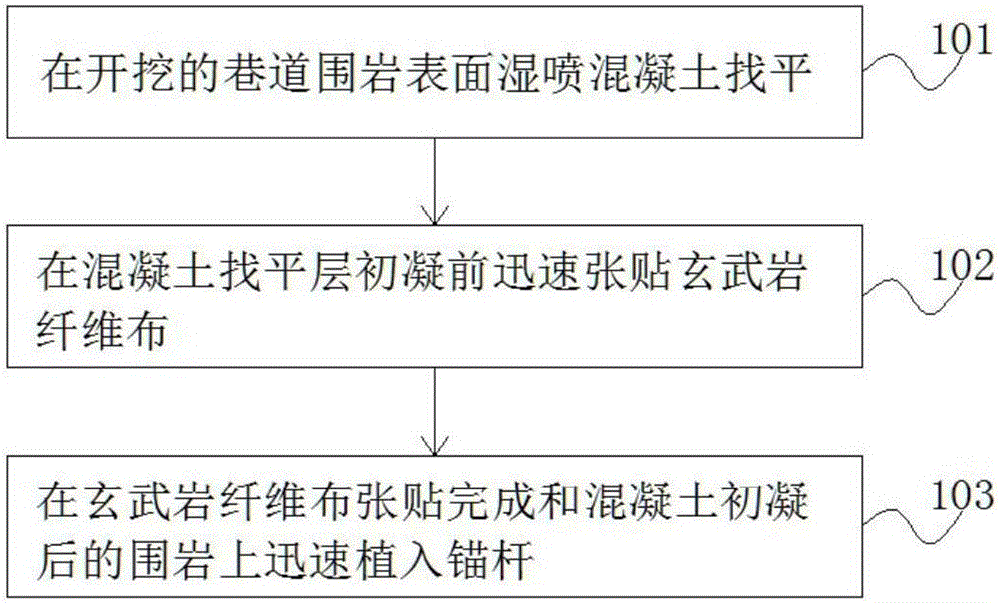

[0032] The construction steps of embodiment are as follows:

[0033] In step 101, a leveling layer of wet sprayed concrete is applied on the surface of the surrounding rock of the excavated tunnel.

[0034] Specifically, the tunnel is excavated according to the designed cross-sectional shape, and after the excavation is completed, a concrete leveling layer (30 mm thick can be used) is sprayed on the surface of the surrounding rock of the tunnel using wet spraying technology. The spraying operation is first sprayed upward from the arch foot or the corner of the wall. The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com