A steel cylinder method for processing high-purity arsine

A pure arsine and steel cylinder technology, applied in the method of container discharge, gas treatment/storage purpose, fluid treatment, etc., can solve the problems of small output and no high-purity arsine steel cylinder treatment system, and achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

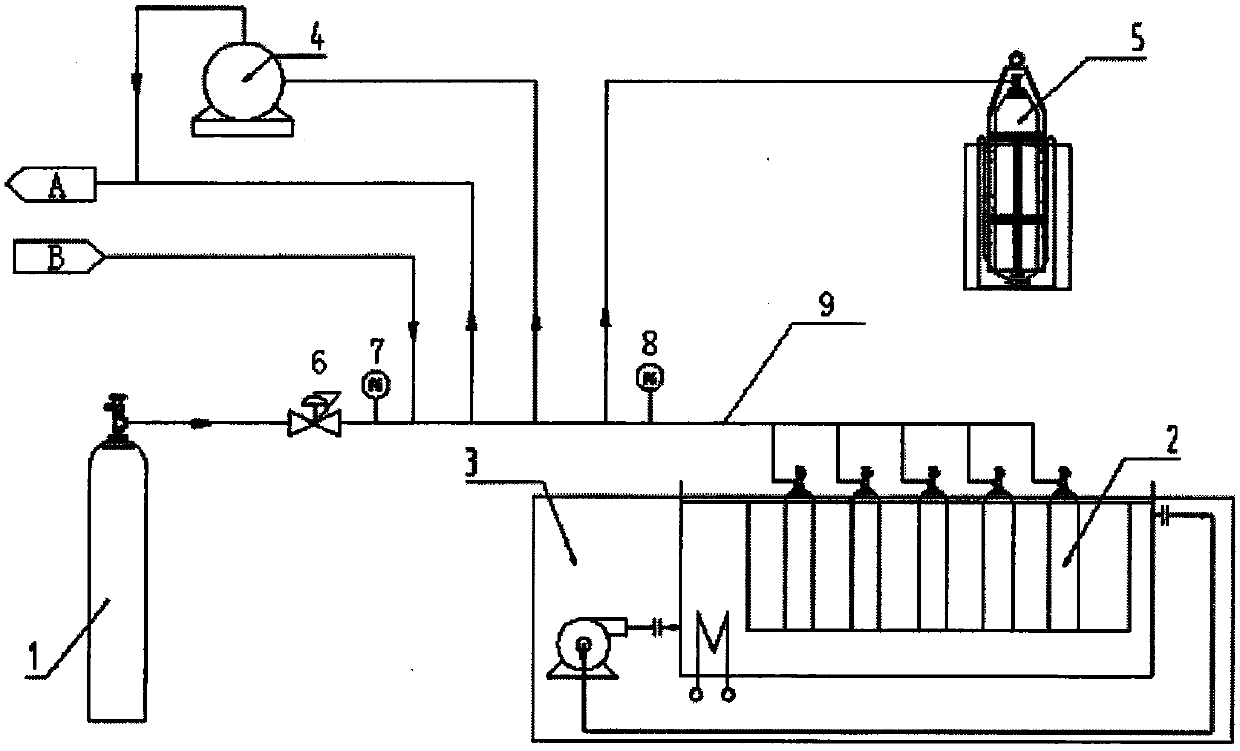

[0022] A method for processing high-purity arsine cylinders:

[0023] Step 1: Use high-purity helium A to replace the entire main pipe 9 to ensure that the pipeline is not polluted, and then use the vacuum pump 4 to vacuum the main pipe 9;

[0024] Step 2: Set the temperature of the oven 3 at 60°C, and keep the vacuum pump 4 running, after the steel cylinder 2 to be treated is vacuum-baked for 8 hours, the steel cylinder 2 to be treated will always be kept at 60-100°C; Fill the cylinder 2 with helium until the pressure gauge 7 displays 1 bar, and then pump the helium gas through the vacuum pump 4 until the vacuum gauge 8 displays 0;

[0025] Step 3: Open the cylinder valve of the source gas cylinder 1, set the pressure of the pressure regulating valve 6 at 1 bar, fill the cylinder 2 to be treated with arsine gas until the pressure gauge 7 shows 0.1 bar, and pass the cylinder 2 to be treated with arsine Baking for 24 hours;

[0026] Step 4: Open the cylinder valve of the cold trap col...

Embodiment 2

[0030] A method for processing high-purity arsine cylinders:

[0031] Step 1: Use high-purity helium A to replace the entire main pipe 9 to ensure that the pipeline is not polluted, and then use the vacuum pump 4 to vacuum the main pipe 9;

[0032] Step 2: Set the temperature of the oven 3 at 100°C, and keep the vacuum pump 4 running, after the steel cylinder 2 to be treated is vacuum-baked for 4 hours, the steel cylinder 2 to be treated is always maintained at 60~100°C; Fill the cylinder 2 with helium until the pressure gauge 7 displays 1.5 bar, and then pump the helium gas through the vacuum pump 4 until the vacuum gauge 8 displays 0;

[0033] Step 3: Open the cylinder valve of the source gas cylinder 1, set the pressure of the pressure regulating valve 6 at 3 bar, fill the cylinder 2 to be treated with arsine gas until the pressure gauge 7 shows 0.5 bar, and pass the cylinder 2 to be treated with arsine Baking for 12 hours;

[0034] Step 4: Open the cylinder valve of the cold trap...

Embodiment 3

[0038] A method for processing high-purity arsine cylinders:

[0039] Step 1: Use high-purity helium A to replace the entire main pipe 9 to ensure that the pipeline is not polluted, and then use the vacuum pump 4 to vacuum the main pipe 9;

[0040] Step 2: Set the temperature of the oven 3 at 80°C, and keep the vacuum pump 4 running, after the steel cylinder 2 to be treated is vacuum-baked for 6 hours, the steel cylinder 2 to be treated is always maintained at 60-100°C; Fill the cylinder 2 with helium until the pressure gauge 7 displays 1.3 bar, and then pump the helium gas through the vacuum pump 4 until the vacuum gauge 8 displays 0;

[0041] Step 3: Open the cylinder valve of the source gas cylinder 1, set the pressure of the pressure regulating valve 6 to 2 bar, fill the cylinder 2 to be treated with arsine gas until the pressure gauge 7 shows 0.3 bar, and pass the cylinder 2 to be treated with arsine Baking for 18 hours;

[0042] Step 4: Open the cylinder valve of the cold trap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com