Composite sponge and preparation method thereof

A composite sponge and solution technology, applied in medical science, absorbent pads, bandages, etc., can solve problems such as poor absorption of exudate, weak anti-infection performance, poor wet strength, etc., to achieve enhanced repair, obvious antibacterial effect, The effect of high water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

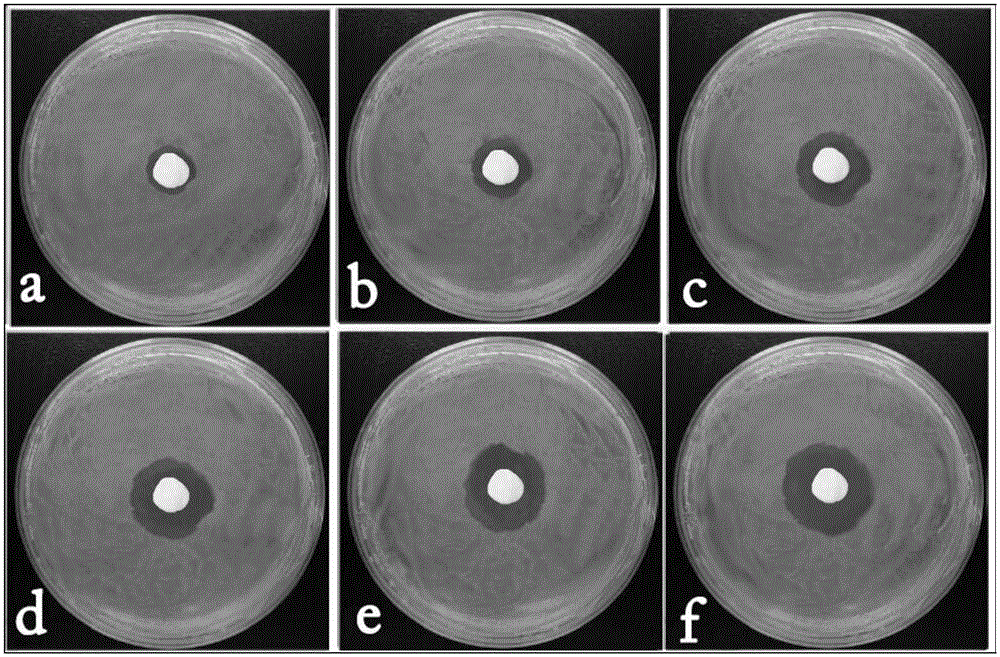

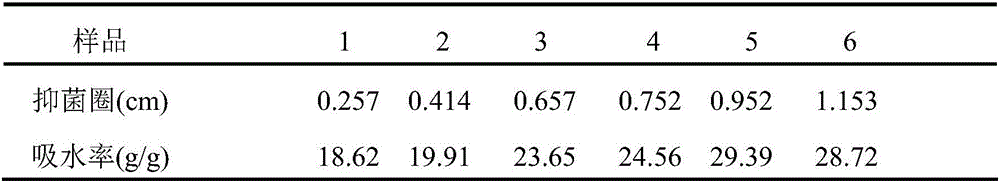

Image

Examples

preparation example Construction

[0021] The preparation method of chitosan quaternary ammonium salt of the present invention is:

[0022] 1) dissolving chitosan powder in glacial acetic acid solution, and then adding sodium hydroxide to the above solution to obtain chitosan precipitation; the precipitation is washed to pH=7.0;

[0023] 2) Disperse the above-mentioned treated chitosan in the isopropanol solution, and after the dispersion is complete, stir, heat and reflux to raise the temperature to 80°C;

[0024] 3) the Virahol solution that will contain 2,3-epoxypropyltrimethylammonium chloride is added dropwise in the above-mentioned solution; Control chitosan and 2,3-epoxypropyltrimethylammonium chloride The molar ratio is 1:4;

[0025] 4) The mixed solution was reacted at 80° C. for 24 hours, cooled, filtered, the filter cake was washed with absolute ethanol and ether in sequence, and vacuum-dried to obtain chitosan quaternary ammonium salt.

[0026] The preparation method of hyaluronic acid-RGD peptide...

Embodiment 1

[0029] Weigh 0.2g of chitosan quaternary ammonium salt, 0.8g of hyaluronic acid-RGD peptide, 1.2g of gelatin, and 1.0g of PVA to make 1%, 4%, 3%, and 5% concentration solutions respectively, and put them in a 250mL flask. Stir evenly, add 0.5g glycerin to the above solution, speed up the stirring rate, stir for 2 hours, and foam, quickly pour the mixture into a petri dish with a radius of 3cm, put it in a refrigerator at about -20°C, and pre-freeze for 24 hours , moved into a freeze-vacuum dryer, and vacuum-dried for 24-48 hours to obtain a composite sponge.

Embodiment 2

[0031] Weigh 0.4g of chitosan quaternary ammonium salt, 1.0g of hyaluronic acid-RGD peptide, 1.6g of gelatin, and 1.5g of PVA to make 2%, 5%, 4%, and 7.5% concentration solutions respectively, and put them in a 250mL flask. Stir evenly, add 1.0g glycerin to the above solution, speed up the stirring rate, stir for 4 hours, and foam, quickly pour the mixture into a petri dish with a radius of 3cm, put it in a refrigerator at about -20°C, and pre-freeze for 24 hours , moved into a freeze dryer, and vacuum-dried for 24-48 hours to obtain a composite sponge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com