Carbon supported nickel nitride catalyst and preparation method and application thereof

A nickel nitride and catalyst technology, applied in the field of catalysis, can solve the problem of poor selectivity for carbon dioxide reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

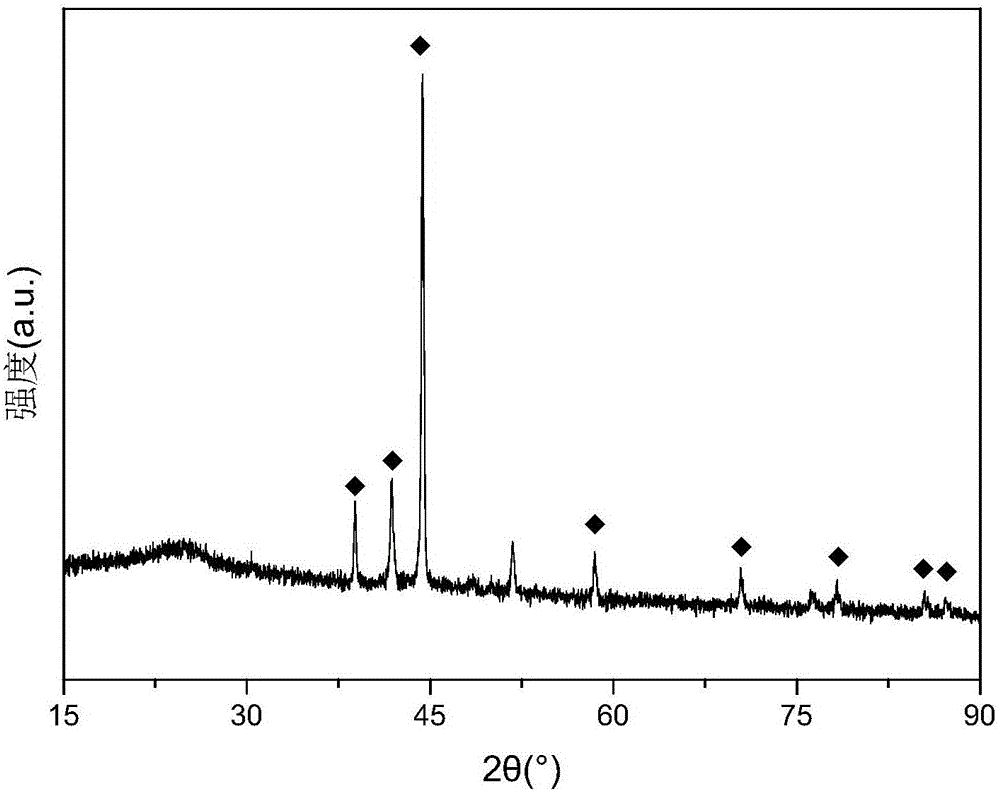

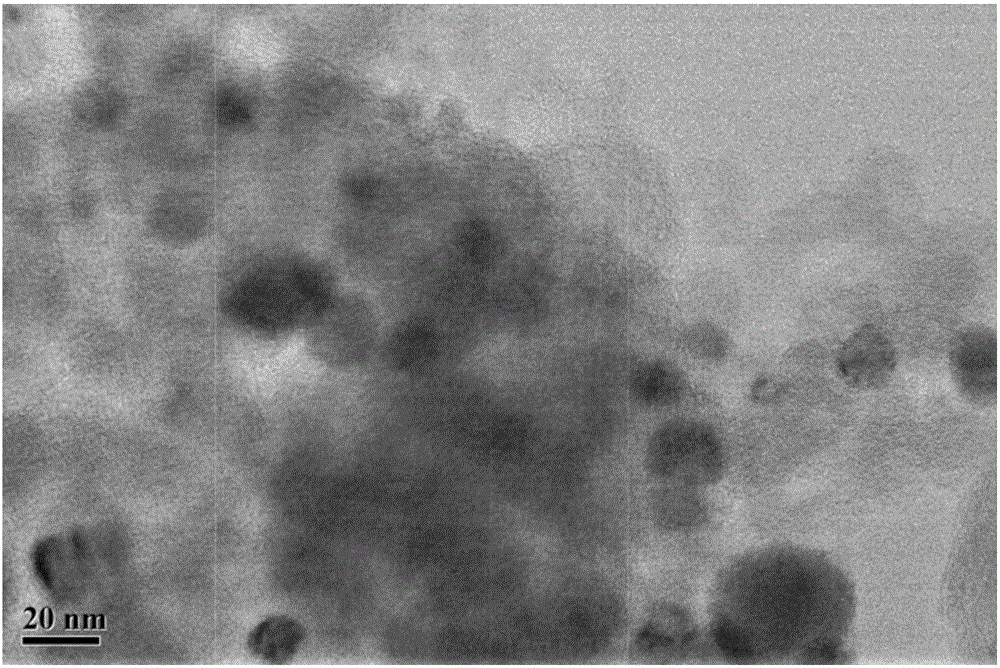

[0051]The preparation method of carbon supported nickel nitride catalyst, the steps are as follows:

[0052] 1) Weigh 1g of nickel nitrate hexahydrate and 1g of VXC-72R conductive carbon black according to the mass ratio of 1:1, add them into 100mL of deionized water, and stir them thoroughly for 12 hours to obtain a uniformly mixed solution;

[0053] 2) Under the condition of 363K oil bath, the above solution was evaporated to dryness to obtain the nickel metal salt precursor Ni / VXC-72R supported by VXC-72R conductive carbon black;

[0054] 3) Dry the obtained Ni / VXC-72R precursor at 423K for 12 hours, and collect it for later use;

[0055] 4) Spread the dried Ni / VXC-72R precursor in a porcelain boat and place it in a tube furnace;

[0056] 5) Introduce ammonia gas for 20 minutes into the tube furnace at a flow rate of 120 mL / min;

[0057] 6) heating up to 973K at a heating rate of 5K / min, and reacting for 3h;

[0058] 7) The temperature was lowered to 573K at a cooling ra...

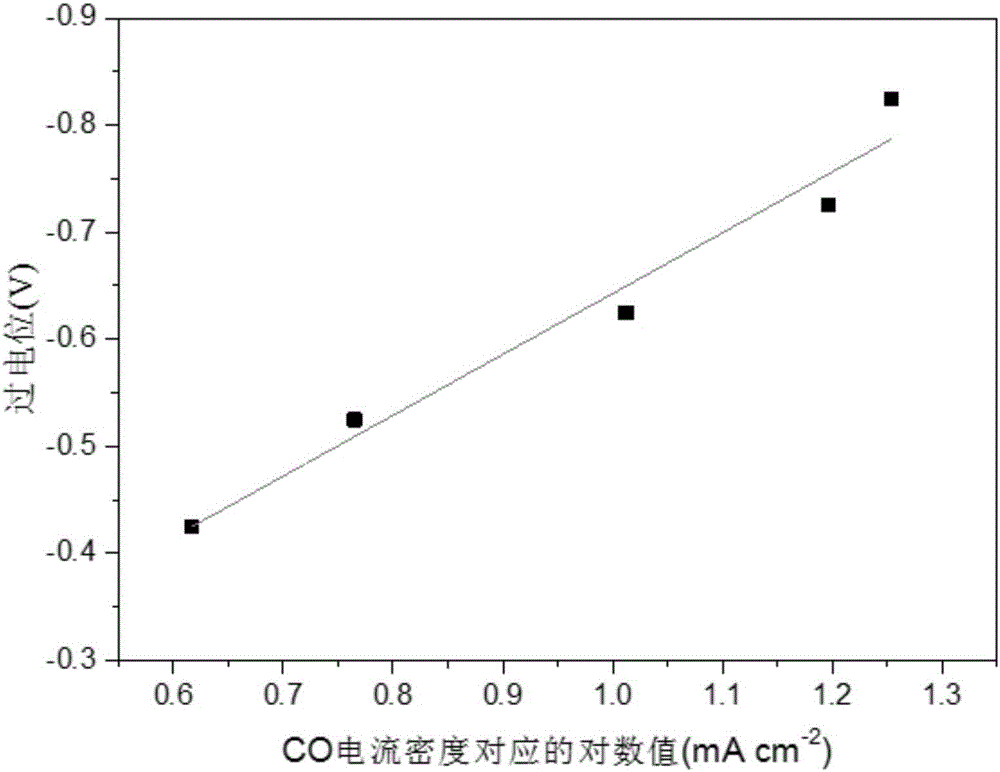

Embodiment 2

[0063] Repeat Example 1, the difference is that the temperature in step 6) is changed from 973K to 673K, and other conditions remain unchanged, and a carbon-supported nickel nitride catalyst is prepared, which is similar in form to Example 1.

Embodiment 3

[0065] Repeat Example 1, the difference is that the temperature in step 6) is changed from 973K to 773K, and other conditions remain unchanged, and a carbon-supported nickel nitride catalyst is prepared, which is similar in form to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com