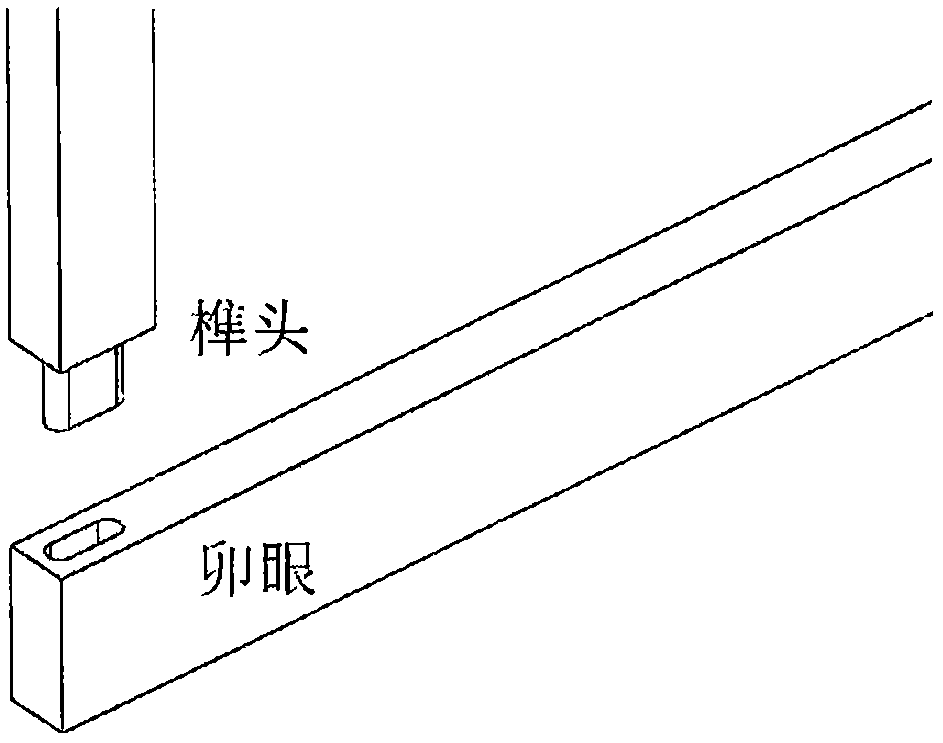

Tenon mortise cutter for solid wood furniture

A cutter and mortise technology, applied in mortising machines, wood processing equipment, mortising devices, etc., can solve the problems of high precision requirements, complex and cumbersome processing, and random adjustments, achieving versatility, flexibility, and simple adjustments The effect of fast and precise adjustment at will

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

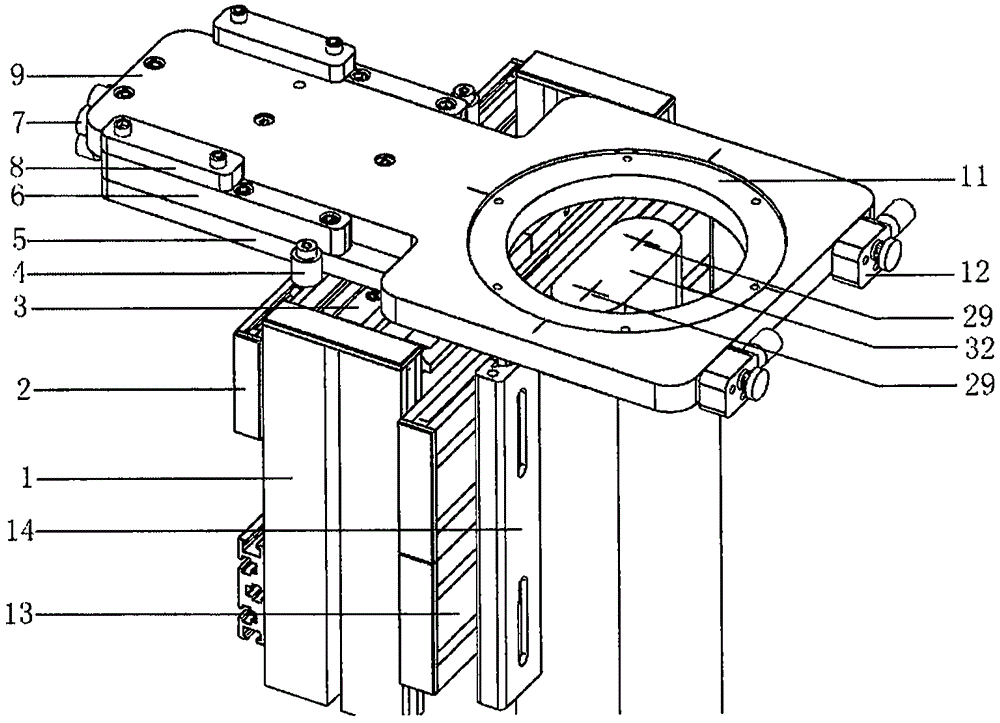

Embodiment 1

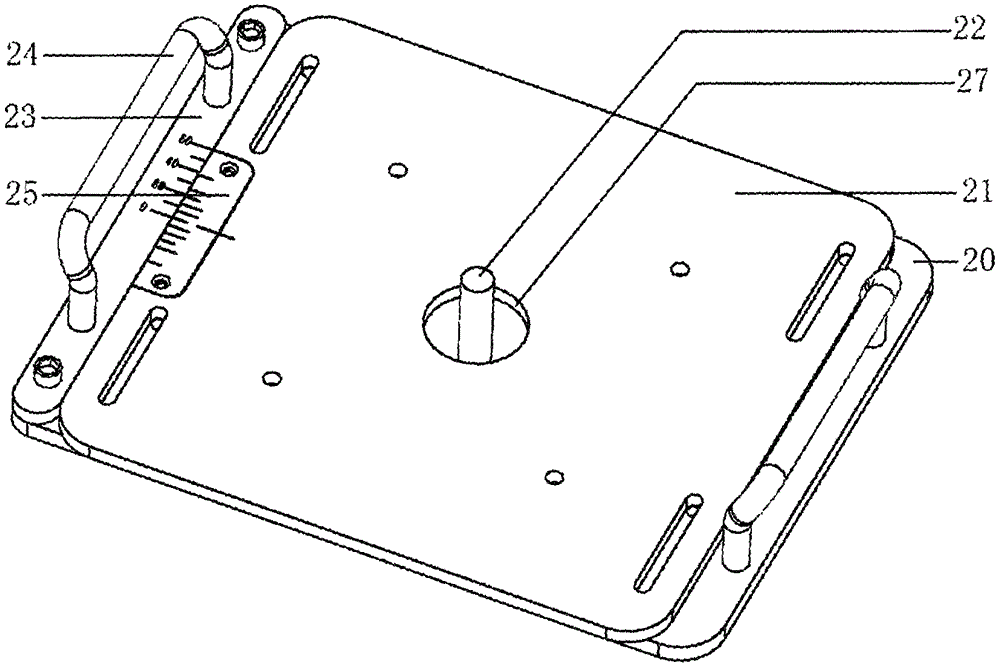

[0023] Example 1. There is a fixed support (1) in the present embodiment, the front of described fixed support (1) is fixed with workpiece backing plate (13), and the workpiece backing plate (13) is fixed with backing mountain (14), will be processed workpiece ( 32) Fix on the workpiece backing plate (13), the side of the workpiece (32) to be processed is close to the backing surface of the backing (14), and the upper plane of the workpiece (32) to be processed is aligned with the bottom surface of the rotating shaft bottom plate (9) , use the clamp to fix the workpiece (32) to complete the positioning of the workpiece. A linear guide rail (3) is fixed above the fixed bracket (1), and a supporting slide block (28) is installed on the linear guide rail (3), and the slide block (28) can slide freely on the linear guide rail (3), The above described slide block (28) is fixed with connection plate (5), is fixed with left and right 2 splints (6) above the connection plate (5), abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com