System and method for producing activated carbon and cogenerating power by using Arundo donax Linn

A reed bamboo, superheated steam technology, applied in chemical instruments and methods, climate sustainability, machines/engines, etc., can solve the problem of adding more surface negative charges, the adsorption capacity of activated carbon is far away, and it is impossible to prepare activated carbon from biomass. Cogeneration power generation and other issues to achieve the effect of improving adsorption performance and reducing demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

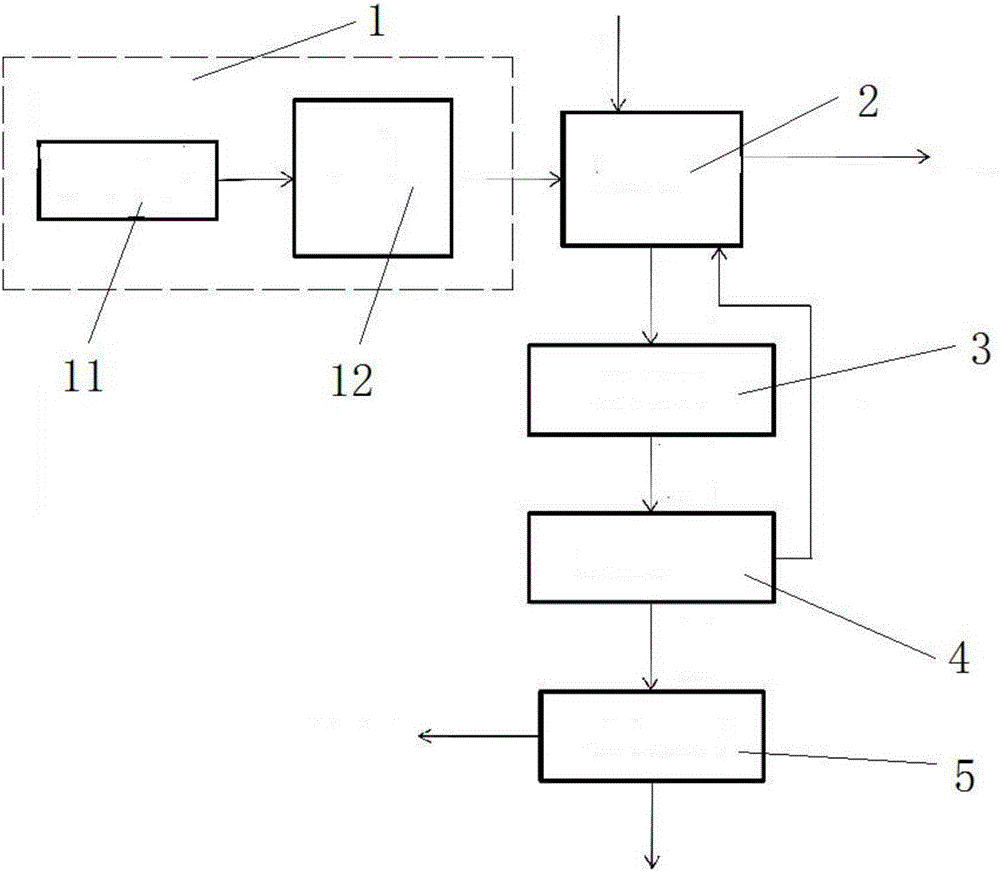

Method used

Image

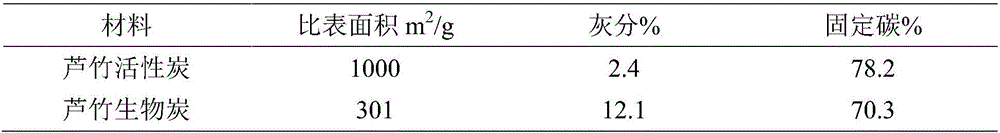

Examples

Embodiment

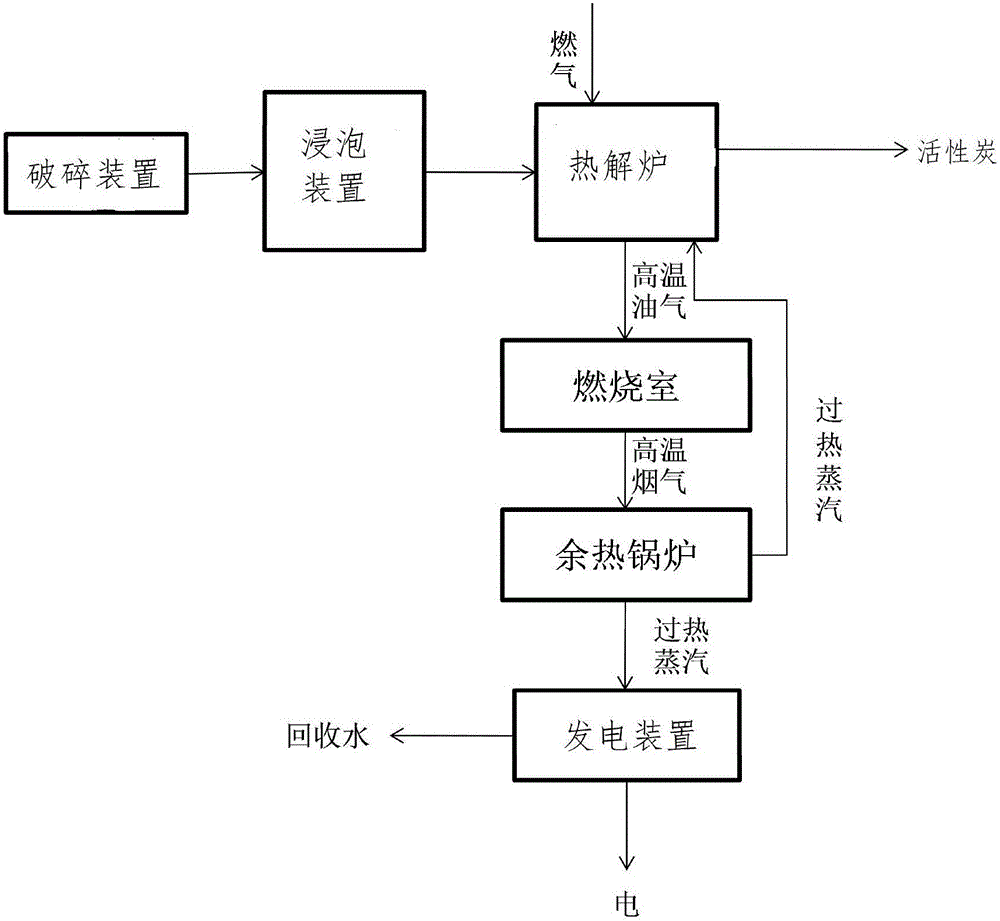

[0063] The raw material of reed bamboo in this embodiment comes from Guangxi Guilin Xingtai Company, and the moisture content of the raw material of reed bamboo is 40.3%. The method for preparing activated carbon cogeneration power generation from Arundis arundis of the present invention, its steps are:

[0064] (1) Raw material preparation: pulverize the raw bamboo bamboo with a water content of 40.3% to about 4-5 cm.

[0065] (2) Pretreatment of reed bamboo stalks: put the reed bamboo stalks obtained in step (1) into the reaction solution for soaking and pretreatment, and the reaction solution is NaOH and H 2 o 2 A mixed aqueous solution composed of 1.5% NaOH, H 2 o 2 The mass fraction is 0.5%; the pretreatment parameters are: solid-to-liquid ratio (g / ml) 1:30, the treatment time is 8 hours, and the pretreated reed bamboo stalks are washed with water.

[0066] (3) Reed bamboo drying and pyrolysis: send the reed bamboo straw washed in step (2) into the regenerative radian...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com