Synthetic method of aldehyde dextran, aldehyde dextran-based coating method, and preparation method of microsphere composition

An aldehyde-based glucan and a synthesis method technology are applied in the preparation of microsphere compositions and the synthesis field of aldehyde-based glucan, and can solve the problems of difficult control of conditions, interference with detection results and the like, and achieve controllable aldehyde-based density, The effect of simple coating process and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

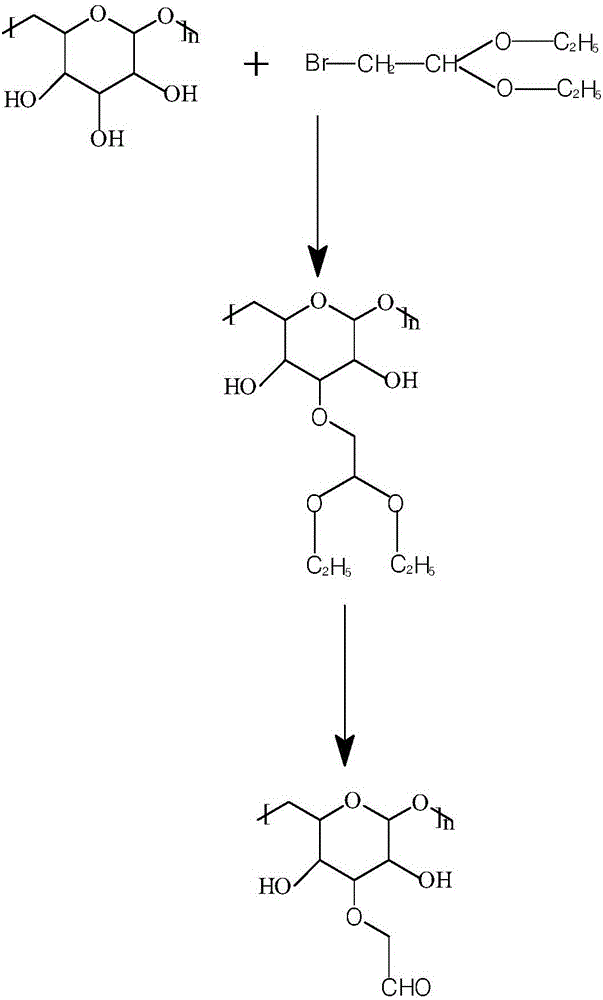

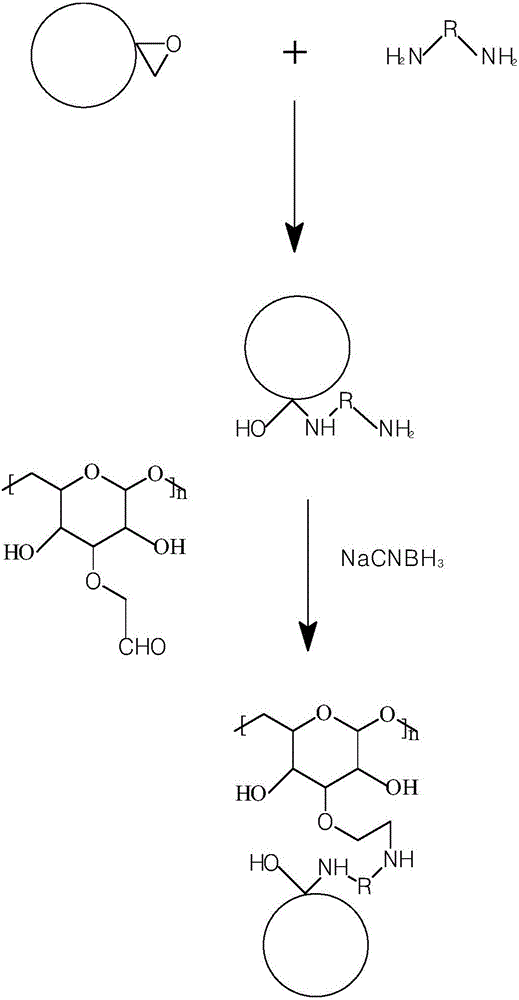

[0093] A synthetic method of aldehyde dextran, comprising the following steps:

[0094] A. After dissolving 30g of dextran in 90ml of water, under nitrogen protection, add 10mg of EDTA, 10mg of 1,4-benzenediol, 10mg of sodium borohydride, 6g of NaOH and 60ml of toluene, and stir and reflux for 2 hours;

[0095] B. Slowly add the toluene solution of 2-bromo-1,1-diethoxyethane dropwise to the system, and the dropping time is not less than 1 hour, the 2-bromo-1,1-diethoxyethane The toluene solution is prepared by dissolving 50ml of 2-bromo-1,1-diethoxyethane in 200ml of toluene solution; after the dropwise addition, stir and reflux for 15 hours;

[0096] C, after being cooled to room temperature, wash the organic phase in the system with water three times, the volume of each water used is 150ml, merge the aqueous phase to obtain an aqueous solution, the aqueous solution is added in the methanol of 2000ml, wash three times with ethanol after suction filtration, each The volume of...

Embodiment 2

[0099] A synthetic method of aldehyde dextran, comprising the following steps:

[0100] A. After dissolving 20g of dextran in 130ml of water, under nitrogen protection, add 5mg of EDTA, 15mg of 1,4-benzenediol, 5mg of sodium borohydride, 8g of NaOH and 40ml of toluene, and stir and reflux for 3 hours;

[0101]B. Slowly add the toluene solution of 2-bromo-1,1-diethoxyethane dropwise to the system, and the dropping time is not less than 1 hour, the 2-bromo-1,1-diethoxyethane The toluene solution is prepared by dissolving 40ml of 2-bromo-1,1-diethoxyethane in 200ml of toluene solution; after the dropwise addition is completed, stir and reflux for 12 hours;

[0102] C, after being cooled to room temperature, wash the organic phase in the system with water three times, the volume of each water used is 180ml, merge the aqueous phase to obtain an aqueous solution, the aqueous solution is added in the methanol of 1500ml, wash three times with ethanol after suction filtration, each Th...

Embodiment 3

[0105] A synthetic method of aldehyde dextran, comprising the following steps:

[0106] A. After dissolving 40g of dextran in 50ml of water, under nitrogen protection, add 15mg of EDTA, 5mg of 1,4-benzenediol, 15mg of sodium borohydride, 4g of NaOH and 80ml of toluene, and stir and reflux for 1 hour;

[0107] B. Slowly add the toluene solution of 2-bromo-1,1-diethoxyethane dropwise to the system, and the dropping time is not less than 1 hour, the 2-bromo-1,1-diethoxyethane The toluene solution is prepared by dissolving 45ml of 2-bromo-1,1-diethoxyethane in 200ml of toluene solution; after the dropwise addition is completed, stir and reflux for 18 hours;

[0108] C, after being cooled to room temperature, wash the organic phase in the system with water three times, the volume of each water used is 120ml, merge the aqueous phase to obtain an aqueous solution, the aqueous solution is added in the methanol of 2500ml, wash three times with ethanol after suction filtration, each Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com