Chromate-free passivation agent for tin-plated steel plate and preparation method of chromate-free passivation agent

A technology of chromium-free passivating agent and tin-plated steel plate, which is applied in the coating process of metal materials, etc., can solve the problems of high cost of passivating agent, unsatisfactory passivating effect, and no chromium-free passivating agent. The effect of low equipment requirements, excellent appearance and quality, and excellent oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

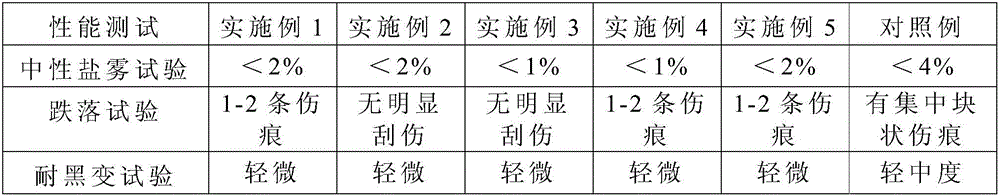

Examples

Embodiment 1

[0022] A chromium-free passivator for tin-plated steel sheets, including the following raw materials in parts by mass: 22 parts of sodium phytate, 6 parts of benzotriazole, 5 parts of sodium carboxymethylcellulose, and 13 parts of rosin-modified phenolic resin 15 parts of concentrated polytetrafluoroethylene dispersion, 4 parts of sodium dodecylbenzenesulfonate, 15 parts of ethanol, and 18 parts of water, wherein the solid content of the concentrated polytetrafluoroethylene dispersion is 58%.

[0023] The preparation method of the chromium-free passivating agent for tin-plated steel sheet described above may further comprise the steps:

[0024] (1) Add carboxymethyl cellulose sodium into water earlier, stir evenly, obtain transparent colloidal solution;

[0025] (2) Add benzotriazole into ethanol, stir evenly, continue to add sodium phytate, rosin-modified phenolic resin and sodium dodecylbenzenesulfonate, and stir at 90r / min for 1-2h to obtain mixture A;

[0026] (3) Add the...

Embodiment 2

[0028] A chromium-free passivator for tin-plated steel sheets, including the following raw materials in parts by mass: 26 parts of sodium phytate, 9 parts of benzotriazole, 7 parts of sodium carboxymethylcellulose, and 15 parts of rosin-modified phenolic resin 18 parts of concentrated polytetrafluoroethylene dispersion, 6 parts of sodium dodecylbenzenesulfonate, 18 parts of ethanol, and 21 parts of water, wherein the solid content of the concentrated polytetrafluoroethylene dispersion is 59%.

[0029] The preparation method of the chromium-free passivating agent for tin-plated steel sheet described above may further comprise the steps:

[0030] (1) Add carboxymethyl cellulose sodium into water earlier, stir evenly, obtain transparent colloidal solution;

[0031] (2) Add benzotriazole into ethanol, stir evenly, continue to add sodium phytate, rosin-modified phenolic resin and sodium dodecylbenzenesulfonate, stir at 95r / min for 1-2h, and obtain mixture A;

[0032] (3) Add the t...

Embodiment 3

[0034] A chromium-free passivator for tin-plated steel sheets, including the following raw materials in parts by mass: 30 parts of sodium phytate, 11 parts of benzotriazole, 8 parts of sodium carboxymethylcellulose, and 17 parts of rosin-modified phenolic resin , 20 parts of polytetrafluoroethylene concentrated dispersion, 9 parts of sodium dodecylbenzenesulfonate, 21 parts of ethanol, and 25 parts of water, wherein the solid content of the polytetrafluoroethylene concentrated dispersion is 60%.

[0035] The preparation method of the chromium-free passivating agent for tin-plated steel sheet described above may further comprise the steps:

[0036] (1) Add carboxymethyl cellulose sodium into water earlier, stir evenly, obtain transparent colloidal solution;

[0037] (2) Add benzotriazole into ethanol, stir evenly, continue to add sodium phytate, rosin-modified phenolic resin and sodium dodecylbenzenesulfonate, and stir at 100r / min for 1-2h to obtain mixture A;

[0038] (3) Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com