Underground nuclear power station cooling vertical shaft

A technology for nuclear power plants and shafts, applied in the field of nuclear power, can solve the problems of wasting land resources in the site area of nuclear power plants, occupying a large area of natural ventilation cooling towers, increasing construction difficulties and engineering costs, etc., to enhance heat exchange capacity, reduce construction difficulties, The effect of saving engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

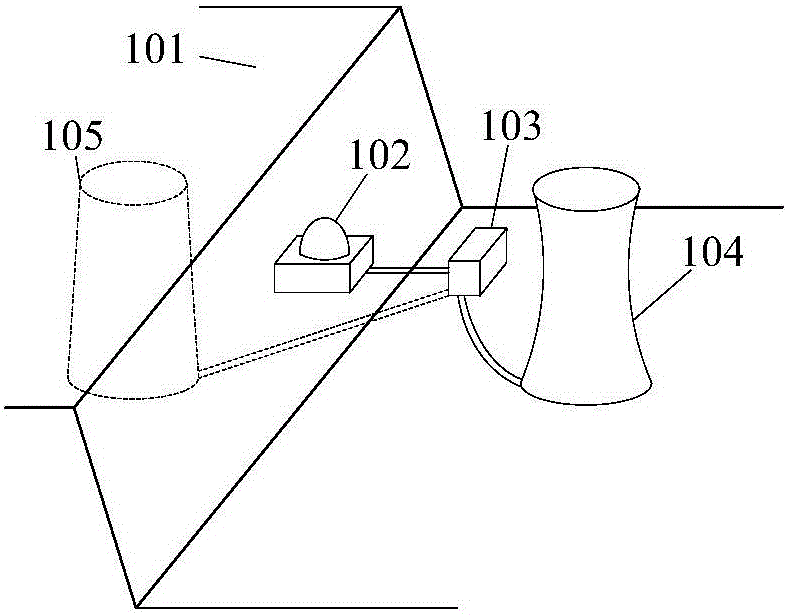

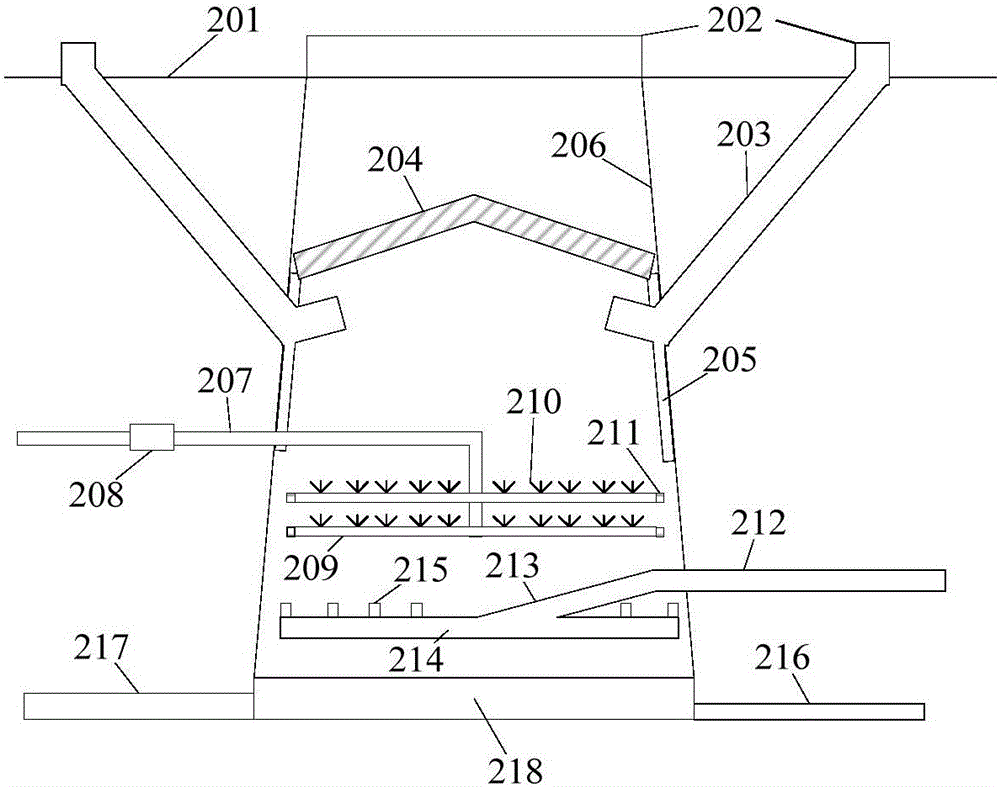

[0020] An underground nuclear power plant cooling shaft 105 of the present invention such as Figure 1 ~ Figure 3 As shown, it includes a frustum-shaped vertical shaft body 206 with an upper opening below the mountain ground 201. A sump 218 is provided at the bottom of the shaft body 206. The sump 218 is provided with a cooling water outlet pipe 217 and a sewage pipe 216. Below the inner cavity of the shaft body 206 There is an air supply system for conveying cold air.

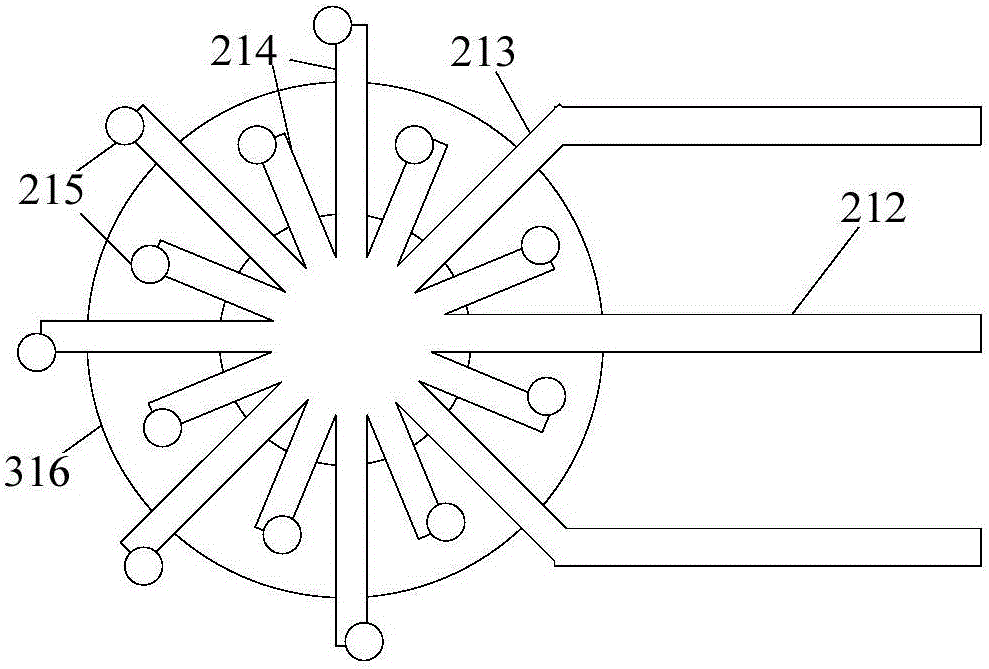

[0021] The air supply system includes an air inlet main pipe 212 , an air inlet distribution pipe 213 and several air inlet branch pipes 214 . One end of the air inlet dry pipe 212 communicates with the cold air source, and the other end communicates with the air inlet distribution pipe 213, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com