Instant black tea processing method

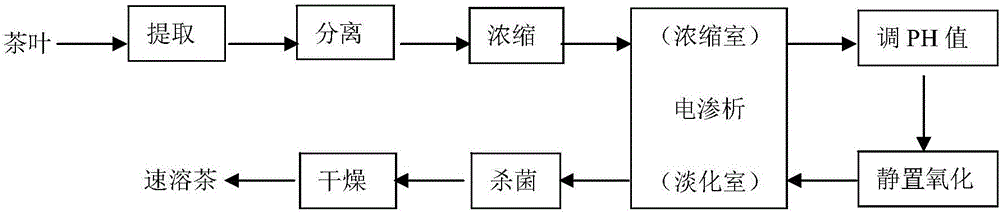

A processing method, instant black tea technology, applied in the direction of tea extraction, etc., can solve the problems of reduced purity of instant tea products, high production costs, affecting quality, etc., to achieve the effect of reducing the production of macromolecular substances, good quality, and improving clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take 1,000kg of green crushed tea, add 13,000kg of water, extract at 90°C for 30 minutes to obtain a green tea extract, and filter it through a disc separator and a ceramic membrane with a pore size of 500nm to obtain a clear and translucent filtrate. Concentrate the above filtrate in a vacuum The equipment is concentrated to obtain 1300kg of tea concentrate with a Brix sugar content of 20°. The above-mentioned green tea concentrate is equally divided into two parts for comparative experiments, each part of 650kg:

[0033] The first part directly added potassium hydroxide to adjust the pH value to 10. After standing for oxidation reaction at 70° C. for 45 minutes, added citric acid monohydrate to adjust the pH value to 5.5. After high-temperature sterilization and spray drying, 169.74 kg of instant black tea was obtained.

[0034] The second batch is divided into 5 batches, each batch is 130kg: the first batch is directly added potassium hydroxide to adjust the pH value ...

Embodiment 2

[0038] Take 400kg of crushed oolong tea, add 6000kg of water, extract at 93°C for 45 minutes to obtain the oolong tea extract, and filter it through a disc separator and a ceramic membrane with a pore size of 500nm to obtain a clear and translucent filtrate, and pass the above filtrate through a vacuum concentration equipment Concentrate to obtain 620kg of tea concentrate with a Brix sugar content of 18°, and divide the above-mentioned oolong tea concentrate into two parts for comparative experiments, each part of 310kg:

[0039] The first part directly added sodium hydroxide to adjust the pH value to 11. After standing for oxidation reaction at 80° C. for 60 minutes, added citric acid monohydrate to adjust the pH value to 5.8. After high-temperature sterilization and spray drying, 71.83 kg of instant black tea was obtained.

[0040] The second batch is divided into 5 batches, each batch is 62kg: the first batch is directly added with sodium hydroxide to adjust the pH value to ...

Embodiment 3

[0044] Take 400 kg of crushed black tea, add 8000 kg of water, and extract at 85°C for 60 minutes to obtain a black tea extract. After filtering through a disc separator and a ceramic membrane with a pore size of 500 nm, a clear and translucent filtrate is obtained. Concentrate through the osmotic membrane to obtain 1040kg of tea concentrate with a Brix sugar content of 10°. The above-mentioned black tea concentrate is equally divided into two parts for comparative experiments, each part of 520kg:

[0045] The first part directly added potassium hydroxide to adjust the pH value to 9.5, and after standing for oxidation reaction at 60° C. for 30 minutes, added citric acid monohydrate to adjust the pH value to 5.3. After high-temperature sterilization and freeze-drying, 67.5 kg of instant black tea was obtained.

[0046] The second batch is divided into 5 batches, each batch is 104kg: the first batch is directly added potassium hydroxide to adjust the pH value to 9.5, and the oxidat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com