Zirconium-modified composite adsorbent and its preparation method and use

A compound adsorption and modification technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve problems such as narrow pH range, low adsorption capacity of fluorine-removing materials, and small mechanical properties. Good mechanical properties, great popularization and application value, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

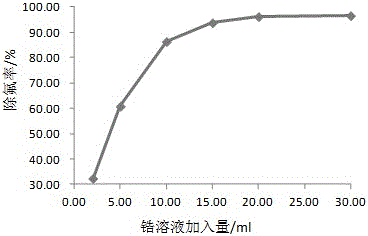

[0039] Example 1 The effect of zirconium oxychloride addition on the defluoridation effect of zirconium modified composite adsorbent

[0040] (1) Take 0.60g chitosan, dissolve in 36ml of 5% acetic acid solution, add different amounts of 0.15mol / L zirconium oxychloride solution (2.00, 5.00, 10.00, 15.00, 20.00, 30.00ml), and use 5% ammonia water Adjusted to pH 5.0 and stirred for 60 minutes;

[0041] (2) Add 1.40g artificial zeolite and 0.50g kaolin and continue to stir for 60min, then adjust to pH 7.5 with 5% ammonia water, let stand for 60min, separate out zirconium-chitosan-zeolite-kaolin (Zr-CZK) composite adsorbent, filter , washed, and dried at 70°C for later use.

[0042] Investigate the defluoridation effect of Zr-CZK composite adsorbents prepared with different additions of zirconium oxychloride. figure 1 . Zr(Ⅳ) ions loaded in composite adsorbent and F in water - F - of adsorption. Therefore, the most important factor affecting the defluoridation performance of ...

Embodiment 2

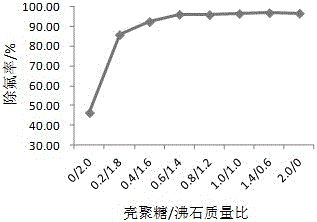

[0043] Example 2 Influence of Chitosan / Zeolite Mass Ratio on Fluoride Removal Effect of Zirconium Modified Composite Adsorbent

[0044] (1) Take different quality chitosan (0.2, 0.4, 0.6, 0.8, 1.0, 1.4g), add 60ml5% acetic acid solution per gram of chitosan, dissolve in 5% acetic acid solution, 0.15mol / L oxygen The zirconium chloride solution add-on is 20ml, and all the other preparation steps are with embodiment 1 (1).

[0045] (2) Add different quality artificial zeolites (1.8, 1.6, 1.4, 1.2, 1.0, 0.6g) and 0.50g kaolin and continue stirring for 60min, and the rest of the preparation steps are the same as in Example 1(2).

[0046] The total mass of fixed chitosan and zeolite is 2.00g, investigate the mass ratio of chitosan / zeolite (0.2 / 1.8,0.4 / 1.6,0.6 / 1.4,0.8 / 1.2,1.0 / 1.0,1.4 / 0.6, i.e. 1: 9, 1:4, 3:7, 2:3, 1:1, 7:3) The influence of the preparation conditions on the defluoridation effect of the composite adsorbent, the results are shown in the attached figure 2 .

[0047]...

Embodiment 3

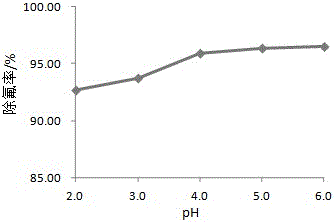

[0048] Example 3 Effect of pH value on composite adsorbent loading zirconium and fluorine removal effect

[0049] (1) Get 0.60g chitosan, be dissolved in 5% acetic acid solution of 36ml, parallel 5 parts, add 20.00ml of 0.15mol / L zirconium oxychloride solution respectively, the first part does not adjust pH (pH is about 2.0), The rest were adjusted to pH=3.0, 4.0, 5.0, and 6.0 with 5% ammonia water, respectively, and stirred for 60 minutes;

[0050] (2) The preparation steps are the same as in Example 1 (2).

[0051] Investigate the modification reaction of zirconium and chitosan to prepare composite adsorbents at different pH values, and the defluoridation effect of the obtained adsorbents. The results are shown in the attached manual. image 3 .

[0052] Depend on image 3 It can be seen that the pH value has a certain influence on the loading of zirconium on the composite adsorbent. In the range of pH 4-6, the loading effect of zirconium is good and the fluorine removal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com