Low-VOC glass fiber reinforced polypropylene burning-slowing composite material and application

A composite material, polypropylene technology, applied in the field of low-VOC glass fiber reinforced polypropylene slow-burning composite materials, can solve the discount of adsorption and degradation ability, can not solve the problems of VOC substances, nano-inorganic powders are easy to agglomerate, etc., to reduce the density , no secondary pollution, less wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

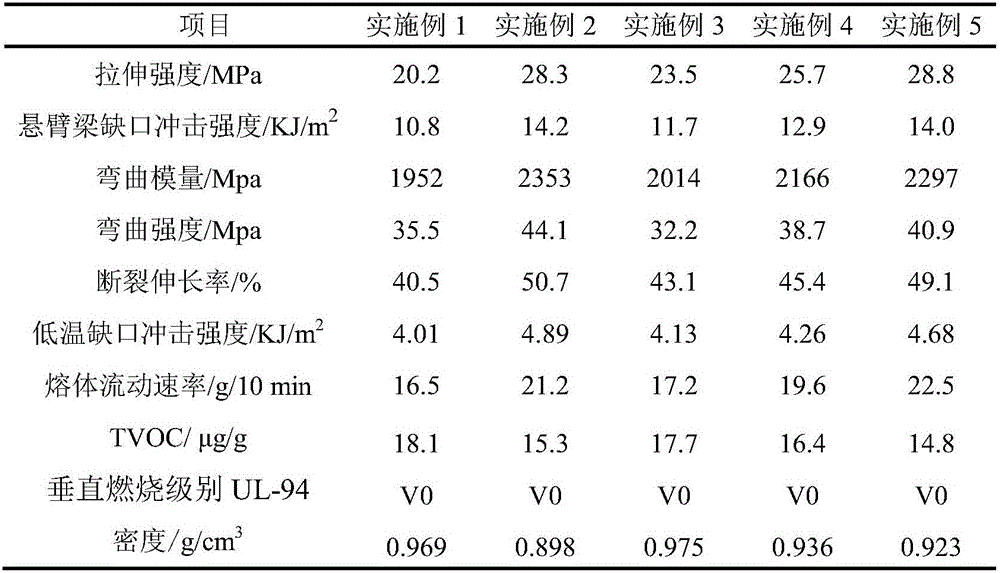

Examples

Embodiment 1

[0025] This embodiment provides a low-VOC glass fiber reinforced polypropylene flame retardant composite material, which comprises the following components in parts by weight:

[0026] 65 parts of polypropylene, 4.5 parts of hollow glass microspheres, wherein the particle diameter of the hollow glass microspheres is 1-3mm, and the surface of the hollow glass microspheres is repeatedly dipped and coated with PP-g-MAH (grafting ratio of 2.5-3.0wt %, melt index is 120-200g / 10min) 1 part, 5-25mm long glass fiber 21.5 parts, talcum powder 3.5 parts, antioxidant 1010 0.2 part, anti-ultraviolet additive CYASORB UV-V680 0.3 part, reactive low bromine 1 part of phosphorus nitrogen flame retardant, 3 parts of VOC inhibitor, wherein the VOC inhibitor includes titanium dioxide quantum dots, attapulgite, sepiolite, diatomaceous earth and tourmaline doped with silver nanoclusters on the surface of 10-20nm, The mass ratio of nano photocatalyst, attapulgite, sepiolite, diatomite and tourmalin...

Embodiment 2

[0029] A kind of low-VOC glass fiber reinforced polypropylene flame retardant composite material, this composite material comprises the components of following parts by weight:

[0030]35 parts of polypropylene, 5 parts of hollow glass microspheres, wherein the particle diameter of the hollow glass microspheres is 1-3mm, and the surface of the hollow glass microspheres is repeatedly dipped and coated with PP-g-MAH (grafting ratio of 2.5-3.0wt %, melt index is 120-200g / 10min) 3 parts, 5-25mm long glass fiber 45 parts, talcum powder 5 parts, antioxidant 0.5 part, this antioxidant is made of antioxidant 1010 and antioxidant 168 according to mass ratio 2 : 1 compound, 0.3 parts of anti-ultraviolet additive CYASORB UV-3808PP5, 2 parts of reactive low bromine phosphorus nitrogen flame retardant, 3 parts of VOC inhibitor, wherein the VOC inhibitor includes 10-20nm surface doped silver Nano clusters of titanium dioxide quantum dots, attapulgite, sepiolite and diatomite, tourmaline and...

Embodiment 3

[0033] A kind of low-VOC glass fiber reinforced polypropylene flame retardant composite material, this composite material comprises the components of following parts by weight:

[0034] 70 parts of polypropylene, 6 parts of hollow glass microspheres, wherein the particle diameter of the hollow glass microspheres is 1-3mm, and the surface of the hollow glass microspheres is repeatedly dipped and coated with PP-g-MAH (grafting ratio of 2.5-3.0wt %, melt index is 120-200g / 10min) 2.3 parts, 5-25mm long glass fiber 15 parts, antioxidant 168 0.2 part, anti-ultraviolet additive CYASORBUV-V680 0.5 part, reactive low bromine phosphorus nitrogen flame retardant 2 parts, 4 parts of VOC inhibitor, wherein the VOC inhibitor includes titanium dioxide quantum dots, attapulgite, sepiolite, and diatomite doped with silver nanoclusters on the surface of 10-20nm, wherein nano-photocatalyst, attapulgite, sea The mass ratio of foam stone and diatomite is 15:30:40:15.

[0035] Above-mentioned raw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com