Enzyme immobilization method and application

A technology for immobilizing enzymes and enzyme liquids, applied to biochemical equipment and methods, and enzymes immobilized on/in organic carriers, etc., can solve problems such as difficulty in ensuring repeatability, limited application range, and complicated processes, and achieve Improve the space-time yield, good repeatability, easy to obtain the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

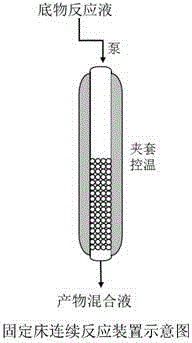

Image

Examples

Embodiment 1

[0027] Embodiment 1 Preparation of carbonyl reductase ChKRED20 immobilized enzyme

[0028] The construction method, heterologous expression, enzyme purification, etc. of the recombinant bacteria of carbonyl reductase ChKRED20 (NCBI accession number: KC342020) are conventional methods in the art. Restriction sites EcoR I and Sal I were added to the two ends of the enzyme gene, and the pET 28a (+) carrier fragment after the same double digestion was connected to obtain the recombinant plasmid pET28a-ChKRED20, which was then transformed into Escherichia coli BL21 ( DE3) to construct recombinant bacteria. The enzyme after heterologous expression of the gene in Escherichia coli has 6 histidines at the N-terminal, which constitutes a histidine tag and can be combined with metal affinity resin.

[0029] Induced expression of carbonyl reductase ChKRED20: Pick a single clone of the recombinant bacteria into LB (containing 50 μg / ml kanamycin) medium, culture at 37°C and 200 rpm for 16 ...

Embodiment 2

[0039] Embodiment 2 Carbonyl reductase ChKRED20 immobilized enzyme and the comparison of pure enzyme biocatalytic efficiency

[0040] (1) Reaction system of pure enzyme: Potassium phosphate buffer (100mM, pH 7.0) contains the following components, 10% (v / v) isopropanol, 0.2g / l NAD + , 2g / l ChKRED20 pure enzyme and substrate 2-chloro-1-(3,4-difluorophenyl)ethanone, concentration 100g / l. 40°C, 200rpm.

[0041] (2) Reaction system of immobilized enzyme: the preparation method of immobilized enzyme is the same as in Example 1. The immobilized enzyme is 2g / l (the concentration refers to the amount of target enzyme contained in the immobilized enzyme), and the rest of the conditions are the same as the pure enzyme reaction system.

[0042]There is no significant difference between the two in the catalytic efficiency at the initial stage of the reaction (the reaction time is 1 hour, and the conversion rate is about 45%). As time goes on, the catalytic efficiency of the immobilized ...

Embodiment 3

[0044] Example 3 Carbonyl reductase ChKRED20 immobilized enzyme catalyzes different concentrations of substrates

[0045] When preparing the immobilized enzyme, the crude enzyme solution was used instead of the pure enzyme solution, and the rest were the same as in Example 1.

[0046] Reaction system: Potassium phosphate buffer (100mM, pH 7.0), 10% (v / v) isopropanol, 0.2g / lNAD + , 5 g / l ChKRED20 immobilized enzyme (the amount of the target enzyme contained), and the substrate 2-chloro-1-(3,4-difluorophenyl)ethanone. The reaction conditions were 40 °C, 200 rpm.

[0047] When the substrate concentration is 50g / l, the time required for complete conversion (conversion rate>99%) is 6h; when the concentration is 100g / l, the time required for complete conversion is 10h; when the substrate concentration is 150g / l, the time required for complete conversion is 24h. Space time yield (Space time yield) is the highest when the substrate concentration is 100g / l, which is 10g / (l.h). When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com