Composite wall adopting fixed-form latent heat storage phase-change material

A composite wall and phase change material technology, applied to walls, climate change adaptation, building components, etc., can solve problems such as waste of manpower and land resources, insufficient wall thickness, and increased wall thickness, so as to improve solar energy utilization efficiency, reducing solar heat loss, and reducing land use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the present invention will be described in detail below in conjunction with preferred embodiments.

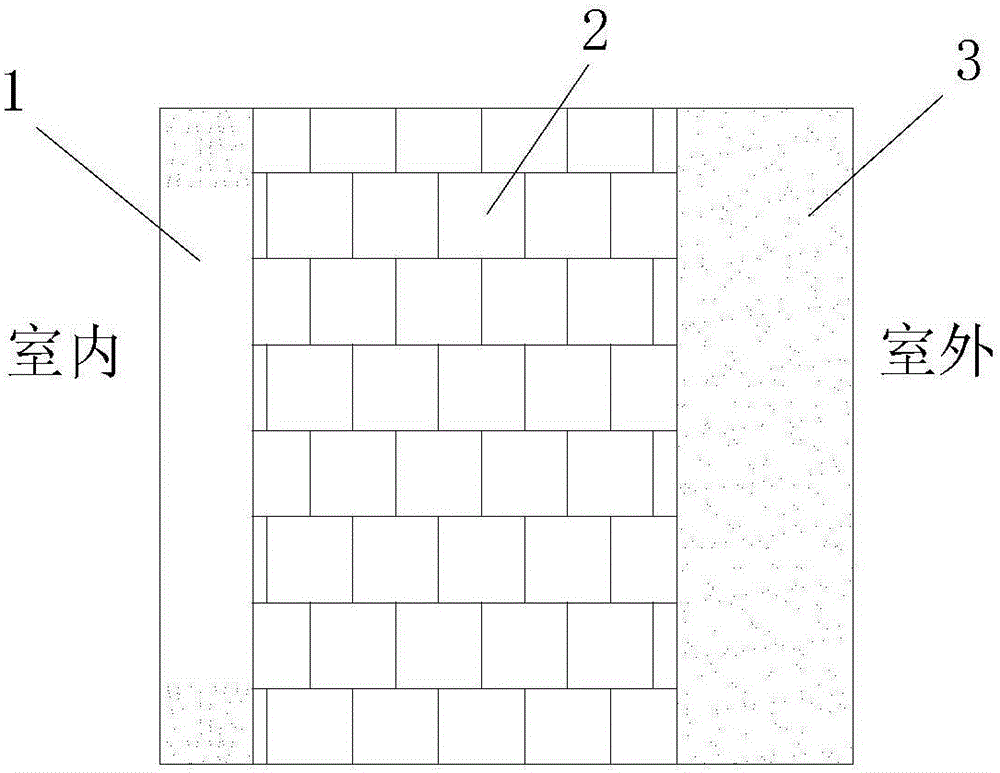

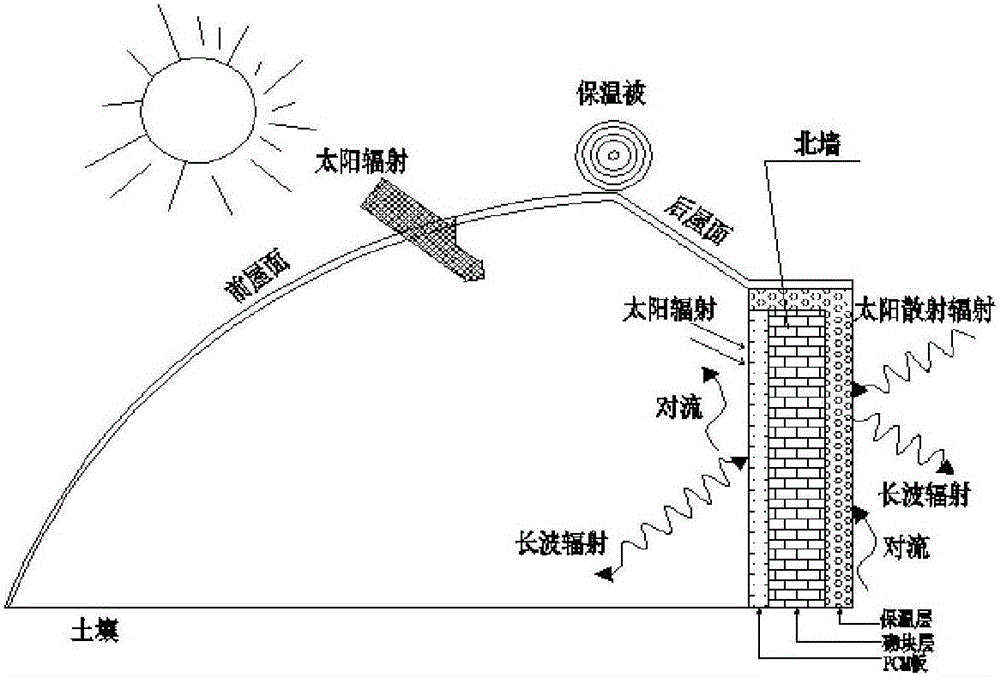

[0018] see attached figure 1 , 2 , this example provides a composite wall using a shaped latent heat storage phase change material, including a wall, the wall includes a phase change heat storage layer, a block layer and an insulation layer connected in sequence from the inside to the outside to form three layers In the structural phase change composite wall, the phase change heat storage layer is placed on the inner side of the north wall, the insulation layer is placed on the outermost side of the north wall, and the block layer is placed between the phase change heat storage layer and the heat preservation layer. The thickness of the phase change thermal storage layer is 10-100mm; the thickness of the block layer is 250-500mm; the thickness of the heat preservation layer is 40-60mm.

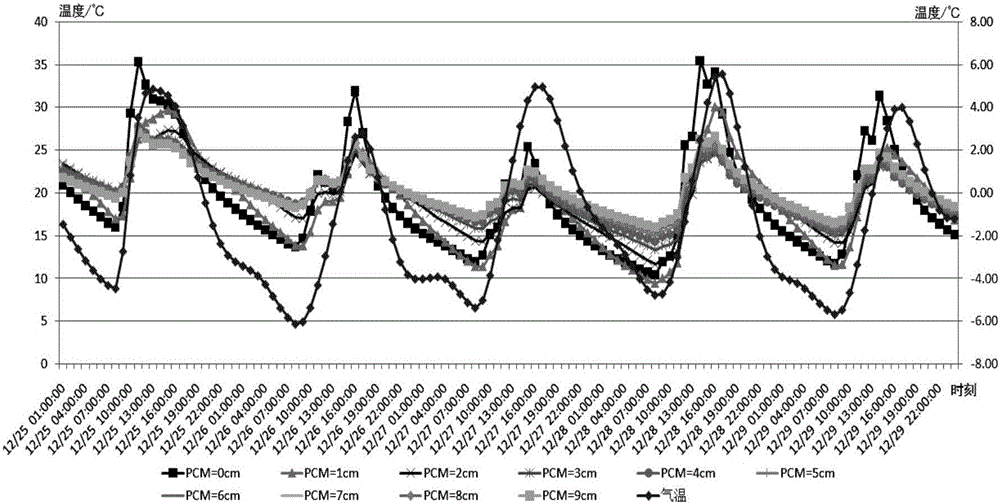

[0019] The optimal thickness of the three-layer str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com