Efficient lithium-based oxygen generation molecular sieve and preparation method thereof

A molecular sieve and lithium-based technology, which is applied in the field of high-efficiency lithium-based oxygen-generating molecular sieves and its preparation, can solve problems such as poor comprehensive performance and affecting the separation effect of pressure swing adsorption oxygen-generating devices, and achieve excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

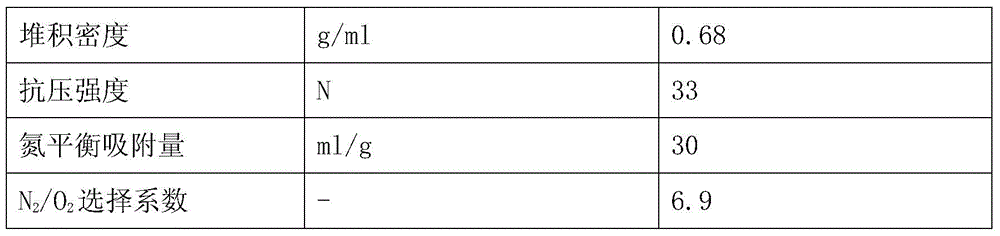

[0016] A high-efficiency lithium-based oxygen-producing molecular sieve, made of the following raw materials by weight (kg): bentonite 30, stilbite 16, laponite 12, palygorskite 13, pyrophyllite 10, pearlite 8, lithium magnesium silicate 4.5, Sodium hydroxide 41, sodium metaaluminate 33, sodium silicate nonahydrate 25, seed crystal directing agent 9;

[0017] The preparation method of described seed directing agent is as follows: a, get the raw material of following weight (kg): bentonite 13, stilbite 8, hectorite 7, sodium metasilicate nonahydrate 25, sodium hydroxide 20, metaaluminic acid Sodium 12; b. Mix bentonite, stilbite and laponite evenly, calcinate at 660°C for 1.5h, cool naturally to room temperature, and mix with sulfuric acid solution with a molar concentration of 1.5mol / L according to the ratio of solid to liquid ratio of 1:18 , heated in a water bath to 75°C, kept warm for 35min, filtered, washed, dried, calcined at 880°C for 2.5h, naturally cooled to room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com