Heteroatom-containing Pi-ligand metallocene complex, preparation method thereof, catalyst system thereof and application of catalyst system

A metallocene complex and heteroatom technology, applied in the field of catalysts, can solve the problem of inability to achieve controllability of polyolefin materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

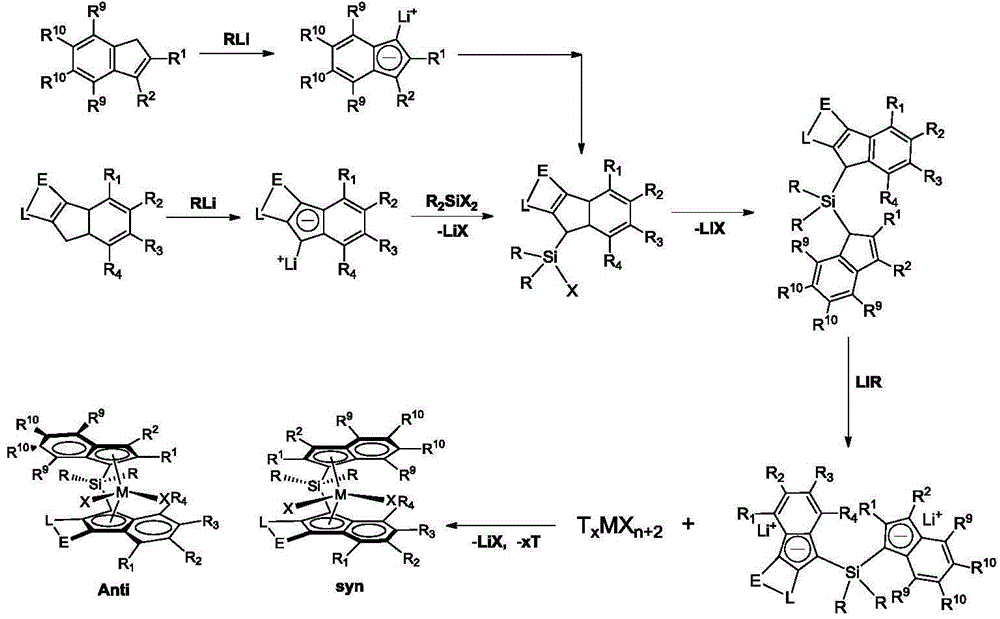

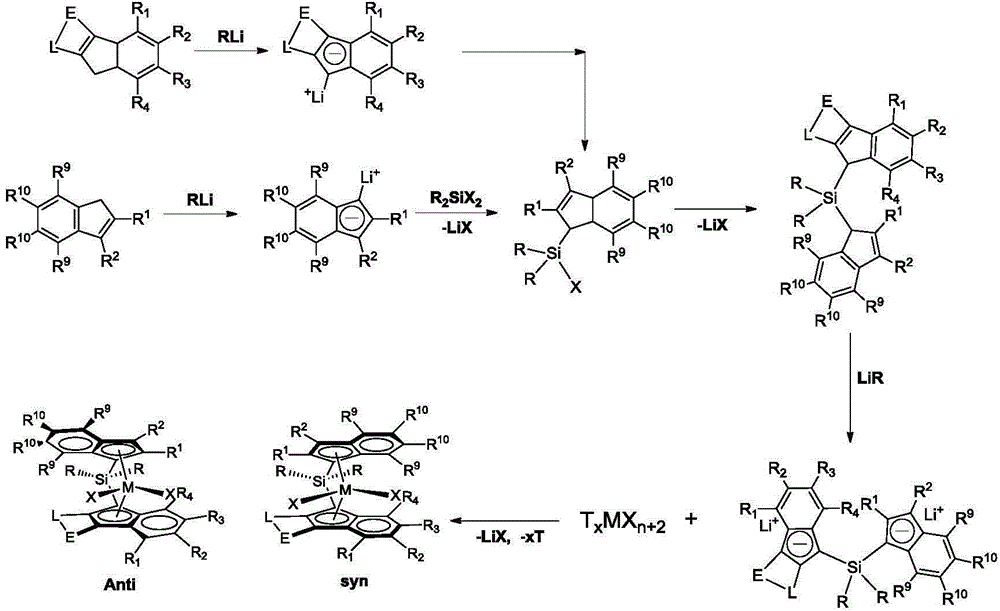

Method used

Image

Examples

Embodiment 1

[0188] Intermediate product a 1 Synthesis:

[0189]

[0190] The intermediate product a in the reaction formula 1 Synthesis:

[0191] Using phenylboronic acid as a substrate, the catalyst, tetrabutylammonium bromide (TBAB) and ethylene glycol are separated from the product by 3:1 PE / EA (petroleum ether / ethyl acetate), and reused (TBAB and ethylene glycol) Alcohol), the third reaction can obtain 82.2% separation yield.

[0192]

[0193] Intermediate product b 1 Synthesis:

[0194] Weigh the intermediate product a 1 Put 5mmol into a 100ml two-necked reaction flask, add 40ml of THF (tetrahydrofuran), put it in an ice-water bath to fully cool; add Red-Al dihydrobis(2-methoxyethoxy)sodium aluminate) dropwise, and use 15min After adding all the drops, react for 2 hours, warm up to room temperature, and react overnight at room temperature; prepare 10% HCl solution and add it dropwise to the reaction system, a white solid precipitates out, making the system acidic; filter ...

Embodiment 2

[0213] Z 2 The synthesis of is as follows, and other conditions are as in Example 1.

[0214]

[0215] product intermediate a 2 Synthesis:

[0216] Calculate the amount of raw materials according to the amount of 1mol product, and put it in a 2500ml two-necked reaction flask; stir for 20min under ice-water bath conditions; weigh dibromo-2-methylpropionyl bromide and anhydrous dichloromethane into the separatory funnel Slowly add dropwise in the reaction bottle; Weigh naphthalene and anhydrous dichloromethane and join in the separatory funnel, slowly dissolve in the reaction system after quickly dissolving, the color of the solution in the reaction bottle becomes yellow rapidly, and gradually becomes brownish red, Finally, add anhydrous dichloromethane to rinse the separating funnel; after reacting for 30min, take out the ice, and slowly warm the water bath to room temperature; The raw materials for the reaction, the organic phase is collected after liquid separation; the...

Embodiment 3- Embodiment 24

[0223] According to the conditions of Example 1, the structure and synthetic method of intermediate product a are as follows:

[0224]

[0225] Sequentially weigh 4-bromo-2-methyl-1-indanone (0.056g, 0.25mmol), phenylboronic acid Ar-B(OH) 2 (0.3mmol), potassium carbonate K 2 CO 3 (0.069g, 0.5mmol), PEG-400 (polyethylene glycol-400) (2g), tetrabutylammonium bromide TBAB (0.08g, 0.25mmol), plus catalyst palladium acetate Pd (OAc) 2 , heated and stirred at 110°C, the results obtained are shown in the following table.

[0226]

[0227]

[0228]

[0229]

[0230]

[0231] Synthesis of intermediate product b in the reaction formula:

[0232] Weigh 3mmol of the intermediate product a and put it into a 100ml two-necked reaction flask, add 40ml of tetrahydrofuran THF, and put it in an ice-water bath to cool fully; add red aluminum Red-Al dropwise, and add it all dropwise in 15min, react for 2h, warm up to room temperature, room temperature React overnight; prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com