Gallium source automatic supply and recovery device

A recovery device and gallium source technology, applied in the field of gallium source automatic replenishment and recovery device, can solve the problems of unable to replenish crystal growth rate and quality recovery and reuse in time, achieve great practical value, improve stability and reliability, guarantee quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

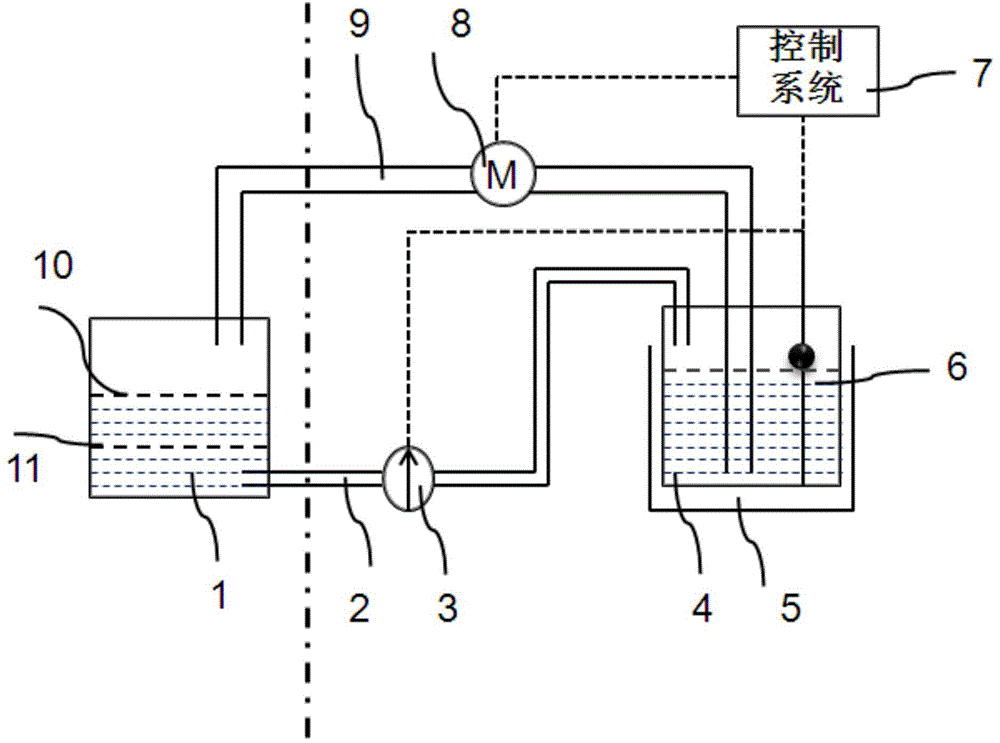

[0026] As shown in the attached figure, an automatic gallium source replenishment and recovery device consisting of a gallium-containing boat, a connector, a control valve, an additional gallium boat, a heater, a liquid level controller, a control system and an engine. When the metal gallium source in the connector is static, the force on both sides is balanced, that is, according to the working principle of the connector: P 1 +ρgH 1 =P 2 +ρgH 2 , where P 1 is the internal pressure of gallium boat 1, H 1 is the liquid level height of metal gallium in gallium boat 1, P 2 is the internal pressure of the additional gallium boat 4, H 2 is the liquid level height of the pipeline in the connector pipeline 2, ρ is the density of metal gallium, and g is the acceleration of gravity, that is, H can be obtained 2 -H 1 =(P 1 -P 2 ) / ρg, and due to static equilibrium, the pressure difference between the pressure in the gallium boat and the pressure in the additional gallium boat 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com