Graphene macroscopic material photocatalytic reduction of CO 2 Equipment and method for preparing methanol

A graphene and CO2 technology, applied in the field of photocatalysis, can solve the problems that the catalyst cannot be reused multiple times, the service life of the catalyst is shortened, and it cannot be reused multiple times, so as to achieve clean utilization, long service life, novel and unique structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

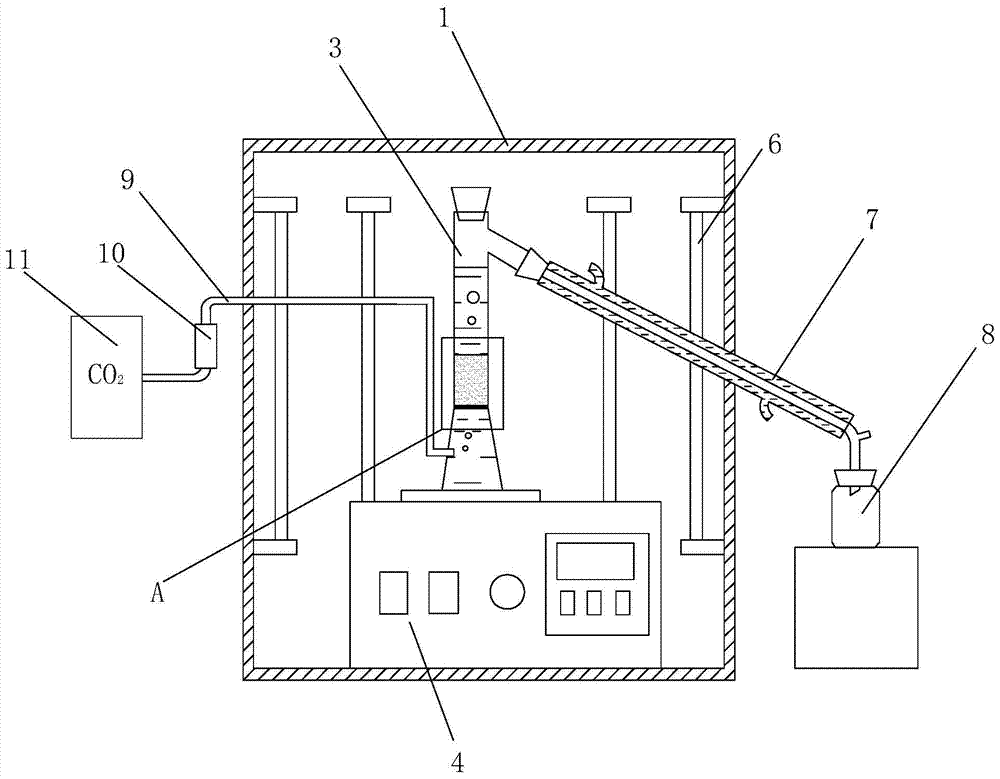

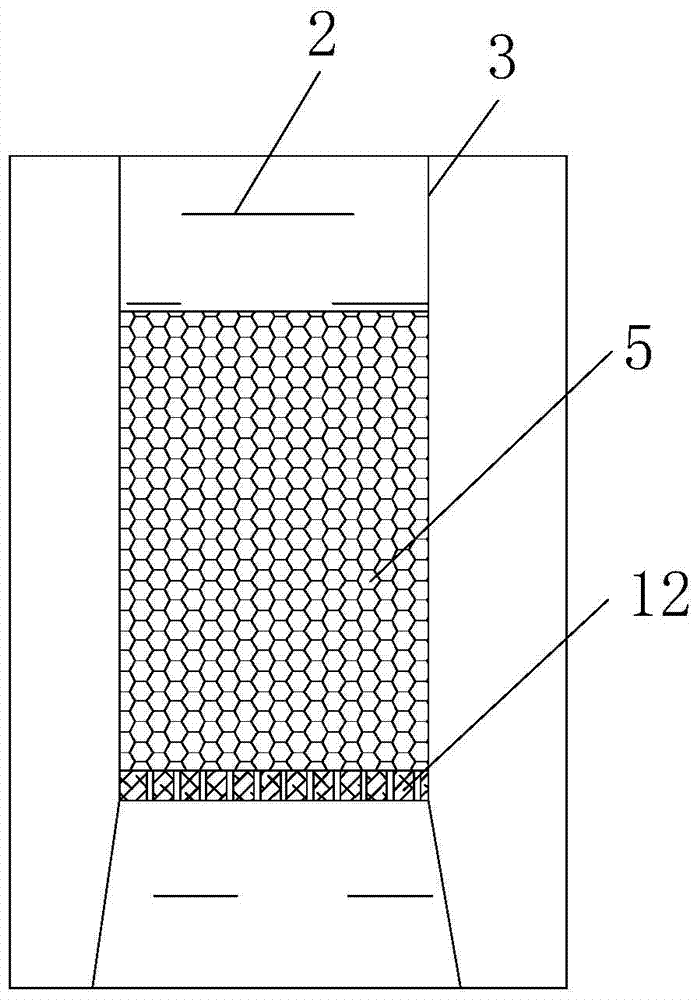

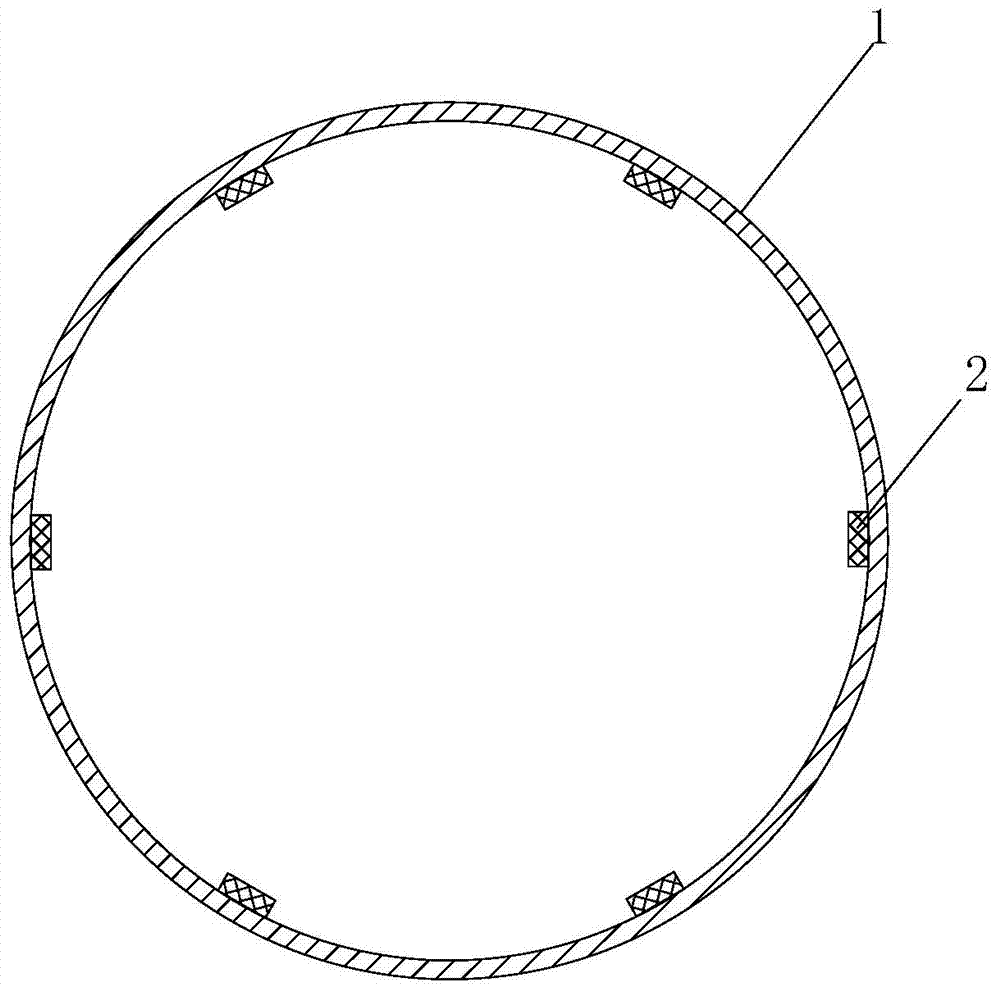

[0049] like Figure 1-2 As shown, the graphene macroscopic material of the present invention photocatalytically reduces CO 2 The equipment for preparing methanol comprises a reaction box 1, the inner wall of the reaction box 1 is provided with a plurality of ultraviolet lamps 6, the reaction box 1 is provided with a reaction bottle 3 for containing the solution medium 2, and the bottom of the reaction bottle 3 A heater 4 for heating the solution medium 2 is provided, the upper part of the reaction bottle 3 communicates with the condensation pipe 7, the condensation pipe 7 communicates with the condensate collection tank 8, and the lower part of the reaction flask 3 passes through CO 2 Pipeline 9 and CO located outside reaction box 1 2 The gas cylinder 11 is connected, and the reaction bottle 3 is provided with a porous partition 12, and the porous partition 12 is provided with a catalyst packing 5, and the CO 2 A flow regulating valve 10 is provided on the pipeline 9 .

[...

Embodiment 2

[0055] combine Figures 1 to 3 , the present embodiment utilizes the equipment described in embodiment 1 to carry out photocatalytic reduction of CO by graphene macroscopic material 2 The method for preparing methanol comprises the following steps:

[0056] Step 1, using anthracite as a raw material to prepare graphene macroscopic materials, the specific process is:

[0057] Step 101, crushing, sieving and ball milling the anthracite successively to obtain particle size D 90 ≤20μm ultra-fine coal powder, then place the ultra-fine coal powder in a graphite crucible and keep it warm for 3 hours at a temperature of 2500°C to obtain graphitized carbon;

[0058] Step 102, using the graphitized carbon described in step 101 as a precursor, adopting the modified Hummers method to prepare coal-based graphene oxide, the specific process is: graphitized carbon, sodium nitrate, potassium permanganate and 98% mass concentration Concentrated sulfuric acid was mixed evenly at a mass ratio...

Embodiment 3

[0071] combine Figures 1 to 3 , the present embodiment utilizes the equipment described in embodiment 1 to carry out photocatalytic reduction of CO by graphene macroscopic material 2 The method for preparing methanol comprises the following steps:

[0072] Step 1, using anthracite as a raw material to prepare graphene macroscopic materials, the specific process is:

[0073] Step 101, crushing, sieving and ball milling the anthracite successively to obtain particle size D 90 ≤20μm ultra-fine coal powder, then place the ultra-fine coal powder in a graphite crucible and keep it warm for 3.5 hours at a temperature of 2500°C to obtain graphitized carbon;

[0074] Step 102, using the graphitized carbon described in step 101 as a precursor, adopting the modified Hummers method to prepare coal-based graphene oxide, the specific process is: graphitized carbon, sodium nitrate, potassium permanganate and 98% mass concentration Concentrated sulfuric acid is mixed evenly at a mass rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com