Fine dried noodles capable of controlling blood sugar and containing tartary buckwheat and okra as well as preparation method

A technology of tartary buckwheat okra and dried noodles, which is applied in the field of sugar-controlled tartary buckwheat and okra noodles and its preparation, which can solve the problems of diabetics who are not full, high rate of broken noodles, rough taste of tartary buckwheat, etc., and achieve a good after-meal Blood sugar, slow release, high rate of broken bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

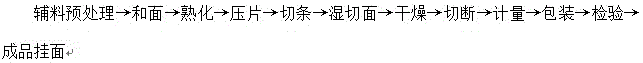

Method used

Image

Examples

Embodiment 1

[0064] A kind of tartary buckwheat and okra vermicelli with sugar control, including common wheat flour, tartary buckwheat fiber powder, high-gluten wheat flour, gluten powder, edible salt, sodium carbonate and water, wherein the mass ratio is wheat common flour: tartary buckwheat fiber powder: high-precision Wheat flour=7:4:1; the amount of other raw materials is calculated based on the total mass of wheat flour, buckwheat fiber powder and high-gluten wheat flour, adding 1% of okra powder, 2% of dietary fiber powder, 0.3-1.2% of gluten powder, yellow Raw gum 0.2%, edible salt 0.1%, sodium carbonate 0.1% and water 25%.

[0065] Tartary buckwheat fiber powder includes tartary buckwheat bark and tartary buckwheat core, the ratio of tartary buckwheat bark and tartary buckwheat core is 1:6.

[0066]Adding gluten (85% wheat gluten) and high-gluten wheat flour (gluten quality ≥ 30%) can increase the gluten content in the dough. The sodium and chloride ions in the salt act as mediato...

Embodiment 2

[0081] A kind of tartary buckwheat and okra vermicelli with sugar control, including common wheat flour, tartary buckwheat fiber powder, high-gluten wheat flour, gluten powder, edible salt, sodium carbonate and water, wherein the mass ratio is wheat common flour: tartary buckwheat fiber powder: high-precision Wheat flour=16:13:7; the amount of other raw materials is calculated based on the total mass of wheat flour, tartary buckwheat fiber powder and high-gluten wheat flour, adding 10% okra powder, 15% dietary fiber powder, 1.2% gluten powder, and xanthan gum 2.0%, edible salt 0.7%, sodium carbonate 0.8% and water 35%.

[0082] Tartary buckwheat fiber powder includes tartary buckwheat skin and buckwheat core, the ratio of tartary buckwheat skin and buckwheat core is 4:9.

[0083] The specific preparation method is as follows:

[0084] (1) Raw material preparation: Weigh each raw material according to the proportion required by the formula;

[0085] (2) Kneading dough: add dr...

Embodiment 3

[0096] A kind of tartary buckwheat and okra vermicelli with sugar control, including common wheat flour, tartary buckwheat fiber powder, high-gluten wheat flour, gluten powder, edible salt, sodium carbonate and water, wherein the mass ratio is wheat common flour: tartary buckwheat fiber powder: high-precision Wheat flour=9:4.5:1; the amount of other raw materials is calculated based on the total mass of wheat flour, buckwheat fiber powder and high-gluten wheat flour, adding 1.1% of okra powder, 2.1% of dietary fiber powder, 0.4% of gluten powder, and xanthan gum 0.3%, edible salt 0.2%, sodium carbonate 0.3% and water 27%.

[0097] Tartary buckwheat fiber powder includes tartary buckwheat skin and buckwheat core, the ratio of tartary buckwheat skin and buckwheat core is 2:7.

[0098] The specific preparation method is as follows:

[0099] (1) Raw material preparation: Weigh each raw material according to the proportion required by the formula;

[0100] (2) Kneading dough: add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com