Composition for preparing empty capsules with modified starch matrixes and empty capsules

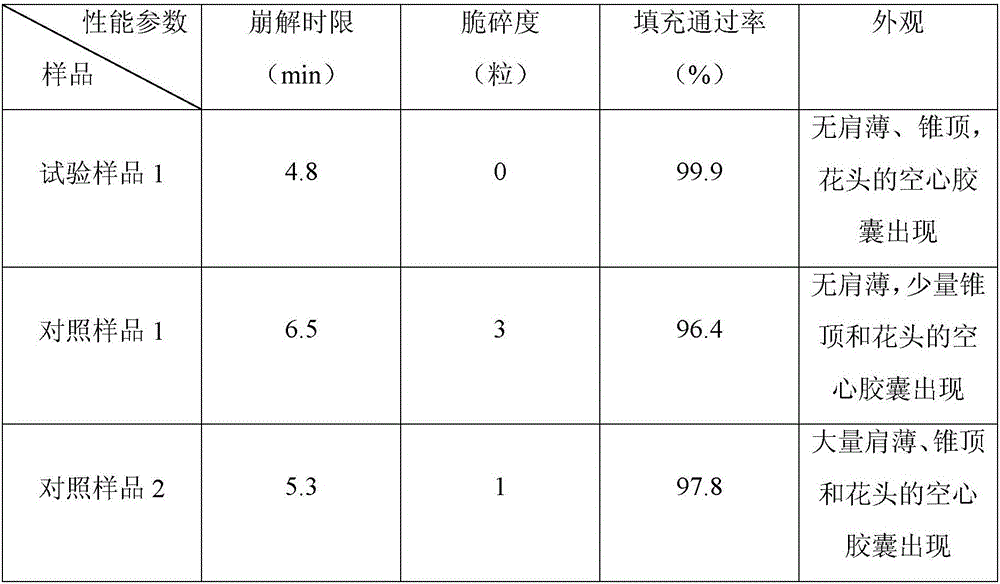

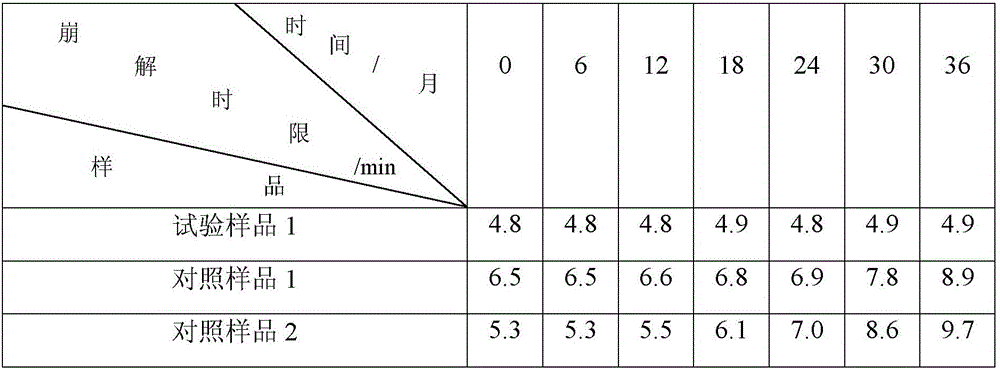

A modified starch and hollow capsule technology, applied in the field of medicine, can solve the problems of unqualified capsule shape, low filling pass rate, long disintegration time, etc., and achieve the effects of improving filling pass rate, maintaining flexibility and strength, and prolonging shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]From 95wt% modified corn starch (calculated on anhydrous basis, containing 2.2wt% acetyl group and 6wt% hydroxyoxy group and crosslinked modified starch by sodium trimetaphosphate, the crosslinking chemical bond is 2000 anhydroglucose units) , 3wt% sorbitol, 1wt% gellan gum, and 1wt% hypromellose were used to prepare the composition of the hollow capsule of the modified starch matrix.

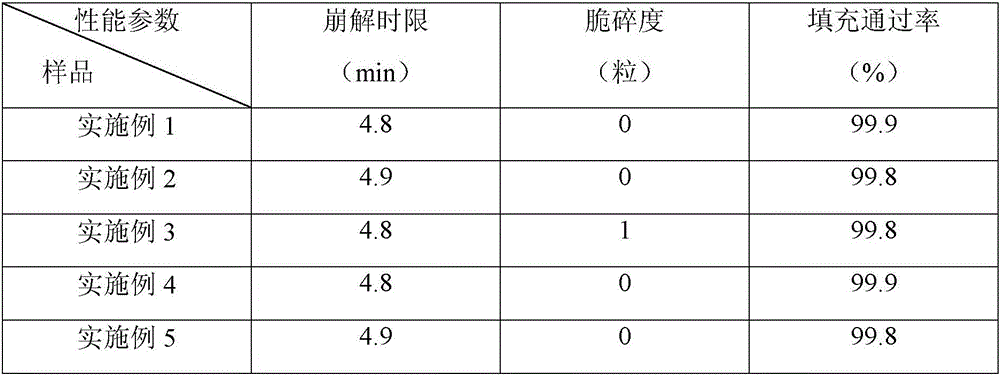

[0031] Mix the above prepared hollow capsule composition for the modified starch matrix with water 6.5 times the weight of the composition and heat to gelatinize and gelatinize. The heating temperature is 70° C. and the heating time is 30 minutes. The hollow capsules were obtained by the conventional preparation process, and the disintegration time limit, friability and filling rate of the prepared hollow capsules were measured respectively, as shown in Table 1.

Embodiment 2

[0033] By 80wt% modified tapioca starch (calculated on anhydrous matter, containing 2.5wt% acetyl group and 6.5wt% hydroxyloxy group and crosslinked modified starch through sodium phosphate trichloride, the crosslinking chemical bond is 1000 anhydroglucose unit), 10wt% xylitol, 5wt% pectin, and 5wt% glycerin are used to prepare the composition of the hollow capsule of the modified starch matrix.

[0034] Mix the above-mentioned composition for preparing hollow capsules of modified starch matrix with water 3 times the weight of the composition and heat to gelatinize and gelatinize. The heating temperature is 95° C. and the heating time is 150 minutes. The hollow capsules were obtained by the conventional preparation process, and the disintegration time limit, friability and filling rate of the prepared hollow capsules were measured respectively, as shown in Table 1.

Embodiment 3

[0036] By 85wt% modified tapioca starch (calculated on anhydrous basis, containing 1wt% acetyl group and 2wt% hydroxyloxy group and crosslinked modified starch through sodium trimetaphosphate, the crosslinking chemical bond is 350 anhydroglucose units), 8wt% of mannitol, 4wt% of carrageenan, and 3wt% of chitosan are used to prepare the composition of the hollow capsule of the modified starch matrix.

[0037] Mix the above-mentioned composition for preparing hollow capsules of modified starch matrix with water 4 times the weight of the composition and heat to gelatinize and gelatinize. The heating temperature is 80° C. and the heating time is 100 minutes. The hollow capsules were obtained by the conventional preparation process, and the disintegration time limit, friability and filling rate of the prepared hollow capsules were measured respectively, as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com