Vanillin microcapsule droplets and preparing method thereof

A vanillin and microcapsule technology, applied in the field of vanillin microcapsule droplets and their preparation, can solve the problem of the controllability of vanillin particle size and morphology is relatively few, inconvenient to use directly, water-soluble It has the effect of increasing pharmacological function, increasing diversity and good biocompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

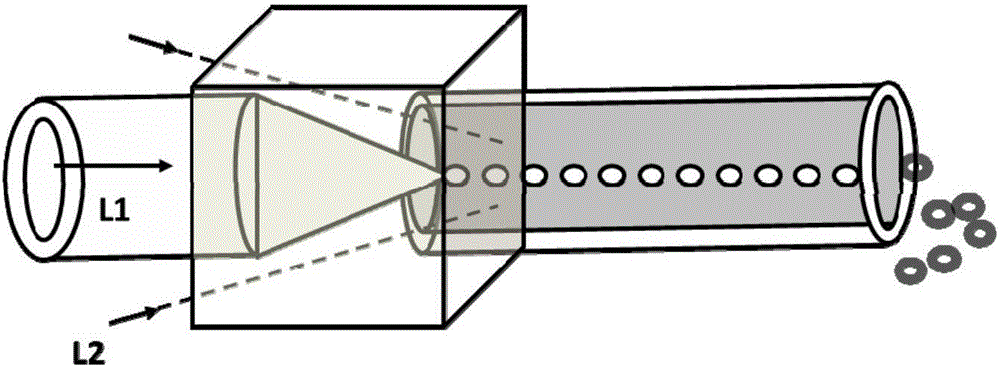

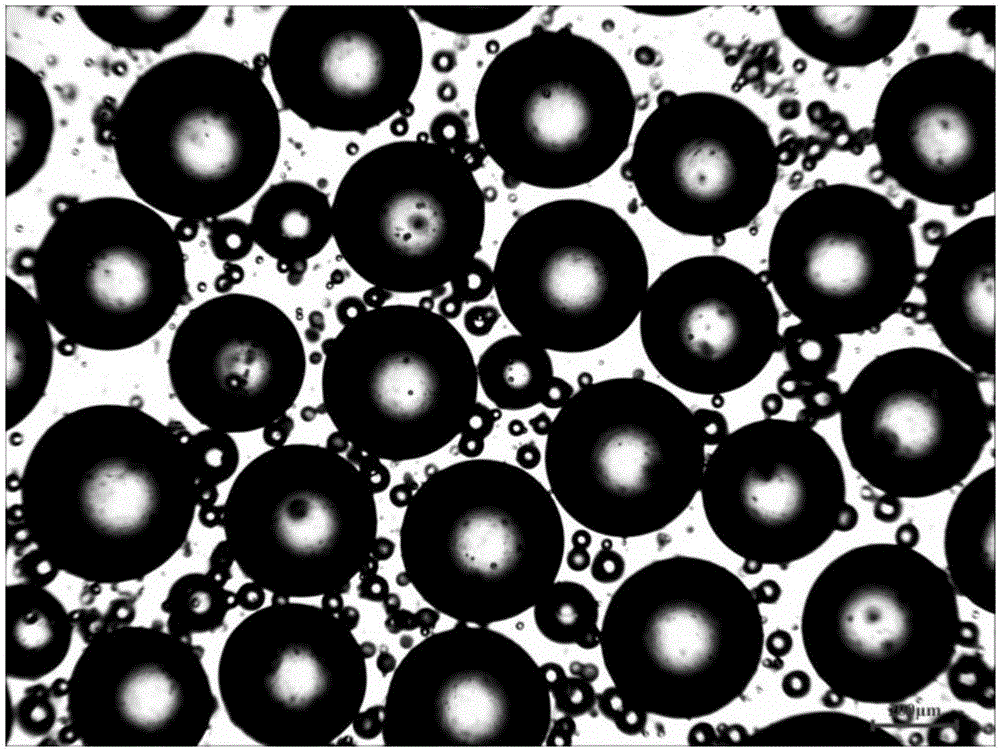

[0033] The process of preparing vanillin / chitosan microsphere droplets by microfluidics: take 0.5g vanillin and dissolve it in 10ml benzyl benzoate and add 0.1g natural extract curcumin to it to color the core material, As L1, take 20ml pre-configured chitosan-acetic acid solution with a pH of 6.5~6.8 as L2. The port size of the constant internal fluid phase is 120 μm, the linear velocity of L1 is adjusted to 215 μm / min, and the linear velocity of L2 is 719 μm / min. L1 and L2 meet at the small hole of the microfluidic device to form a vanillin / chitosan microsphere solution drop.

[0034] Gained vanillin microcapsule liquid drop sees figure 2 According to the microscope picture, the particle size of the obtained microemulsion system is 340 μm.

Embodiment 2

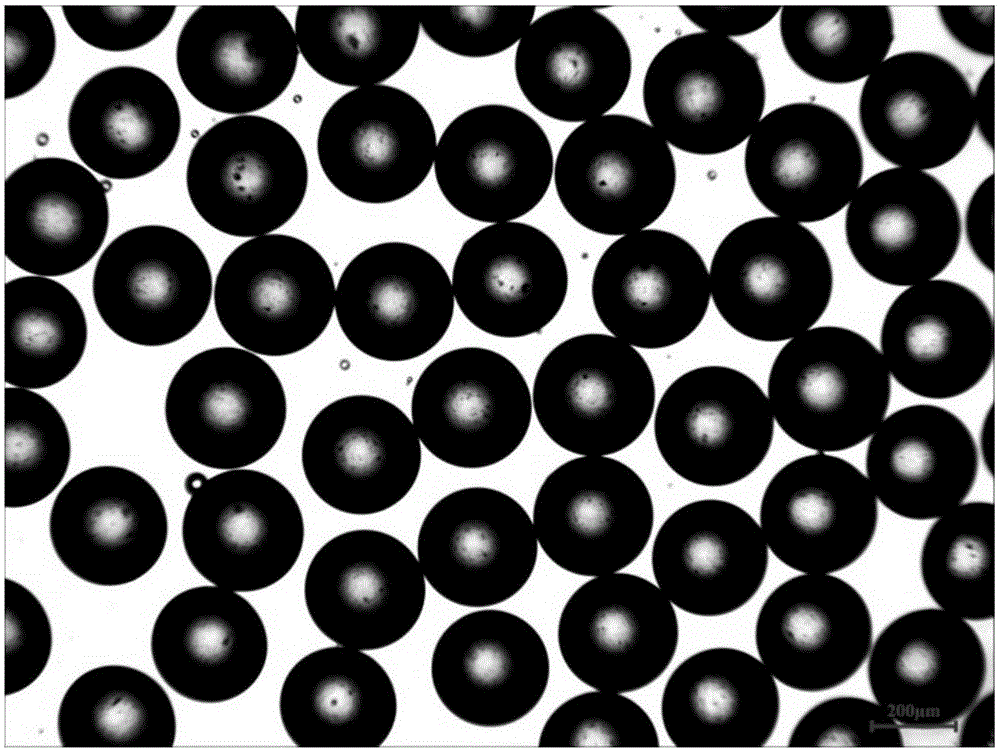

[0036] The process of preparing vanillin / chitosan microsphere droplets by microfluidics: take 0.5g vanillin and dissolve it in 10ml benzyl benzoate and add 0.1g natural extract curcumin to it to color the core material, As L1, take 20ml pre-configured chitosan-acetic acid solution with a pH of 6.5~6.8 as L2. The port size of the constant internal flow phase is 120 μm, the linear velocity of L1 is adjusted to 215 μm / min, and the linear velocity of L2 is 899 μm / min. L1 and L2 meet in the small hole of the microfluidic device to form a vanillin / chitosan microsphere solution drop.

[0037] Gained vanillin microcapsule liquid drop sees image 3 According to the microscope picture, the particle size of the obtained microemulsion system is about 270 μm.

Embodiment 3

[0039] The process of preparing vanillin / chitosan microsphere droplets by microfluidics: take 0.5g vanillin and dissolve it in 10ml benzyl benzoate and add 0.1g natural extract curcumin to it to color the core material, As L1, take 20ml pre-configured chitosan-acetic acid solution with a pH of 6.5~6.8 as L2. The port size of the constant internal flow phase is 120 μm, the linear velocity of L1 is adjusted to 215 μm / min, and the linear velocity of L2 is 1799 μm / min. L1 and L2 meet in the small hole of the microfluidic device to form a vanillin / chitosan microsphere liquid drop.

[0040] Gained vanillin microcapsule liquid drop sees Figure 4 According to the microscopic image, the particle diameter of the obtained microemulsion system is 246 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com