Pig brain extract, composition containing pig brain extract and application of composition

A technology for extracts and compositions, which is applied to medical preparations containing active ingredients, drug combinations, applications, etc., can solve the problems of limited effect and obvious side effects, and achieves the effect of simple method and reduced number of errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

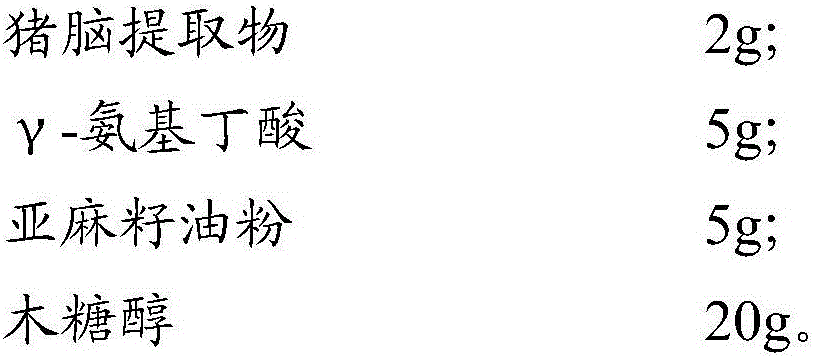

Examples

Embodiment 1

[0063] The preparation of embodiment 1 pig brain extract

[0064] Healthy pig brains were taken, cleaned and removed of connective tissue, then frozen and homogenized.

[0065] For every 1000 g of homogenate, add 2 g of pepsin, adjust the pH value to 1.8, and perform enzymatic hydrolysis at 40°C for 6 hours; then add 2 g of trypsin to adjust the pH value to 7.5, and perform enzymatic hydrolysis at 40°C for 6 hours.

[0066] After enzymatic hydrolysis, the homogenate was filtered through a 300-mesh non-woven fabric to remove the residue, and then passed through a 10kDa filter membrane to remove the residue.

[0067] The filtrate obtained by ultrafiltration is nanofiltered 3 times through a nanofiltration machine (pressure 0.8MPa);

[0068] The resulting filtrate was filtered and freeze-dried.

[0069] The freeze-drying procedure was to freeze at -50°C for 2 hours, and then turn on the vacuum pump. When the vacuum degree is lower than 20Pa, raise the temperature of the frozen...

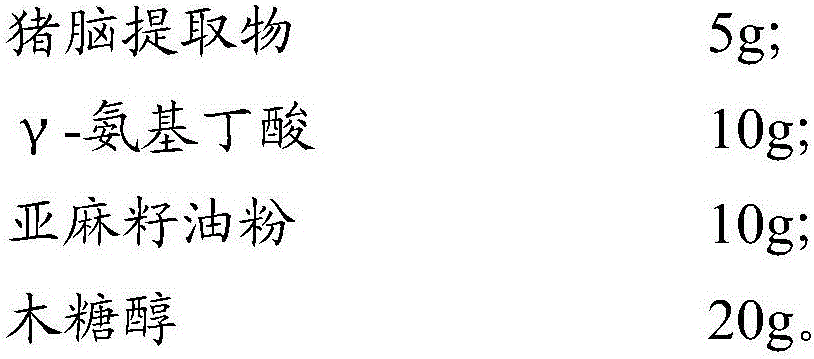

Embodiment 2

[0071] The preparation of embodiment 2 pig brain extract

[0072] Healthy pig brains were taken, cleaned and removed of connective tissue, then frozen and homogenized.

[0073] For every 1000 g of homogenate, add 1 g of pepsin, adjust the pH value to 1.6, and perform enzymatic hydrolysis at 42°C for 7 hours; then add 5 g of trypsin to adjust the pH value to 7.3, and perform enzymatic hydrolysis at 42°C for 5 hours.

[0074] After enzymatic hydrolysis, the homogenate was filtered through a 300-mesh non-woven fabric to remove the residue, and then passed through a 10kDa filter membrane to remove the residue.

[0075] The filtrate obtained by ultrafiltration is nanofiltered 3 times through a nanofiltration machine (pressure 0.8MPa);

[0076] The resulting filtrate was filtered and freeze-dried.

[0077] The freeze-drying procedure was to freeze at -35°C for 4 hours and then turn on the vacuum pump. When the vacuum degree is lower than 20Pa, raise the temperature of the frozen ...

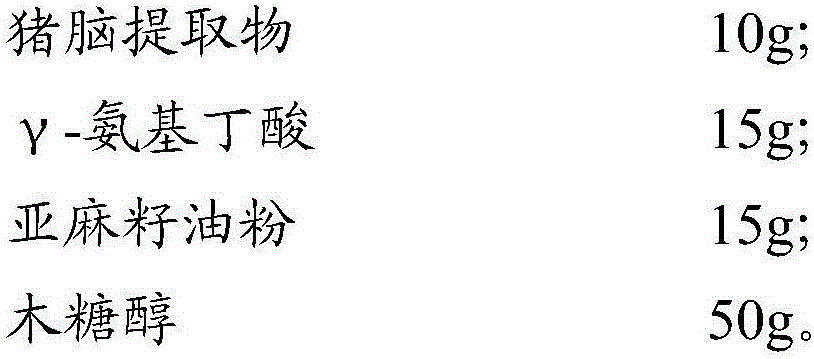

Embodiment 3

[0079] The preparation of embodiment 3 pig brain extract

[0080] Healthy pig brains were taken, cleaned and removed of connective tissue, then frozen and homogenized.

[0081] For every 1000g of homogenate, add 5g of pepsin, adjust the pH value to 2.0, and enzymatically hydrolyze at 38°C for 5h; then add 1g of trypsin to adjust the pH value to 7.7, and enzymolyze at 38°C for 7h.

[0082] After enzymatic hydrolysis, the homogenate was filtered through a 300-mesh non-woven fabric to remove the residue, and then passed through a 10kDa filter membrane to remove the residue.

[0083] The filtrate obtained by ultrafiltration is nanofiltered 3 times through a nanofiltration machine (pressure 0.8MPa);

[0084] The resulting filtrate was filtered and freeze-dried.

[0085] The freeze-drying procedure was to freeze at -43°C for 3 hours and then turn on the vacuum pump. When the vacuum degree is lower than 20Pa, raise the temperature of the frozen product to -20°C and keep the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com