Preparation and application of super tolerance metal chelating affinity packing

A metal chelation and tolerance technology, applied in the field of preparation of protein purification fillers, can solve the problems of free metal ion environmental pollution, physical denaturation damage, reduced use efficiency, etc., achieve strong component compatibility, long service life, and easy to use low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

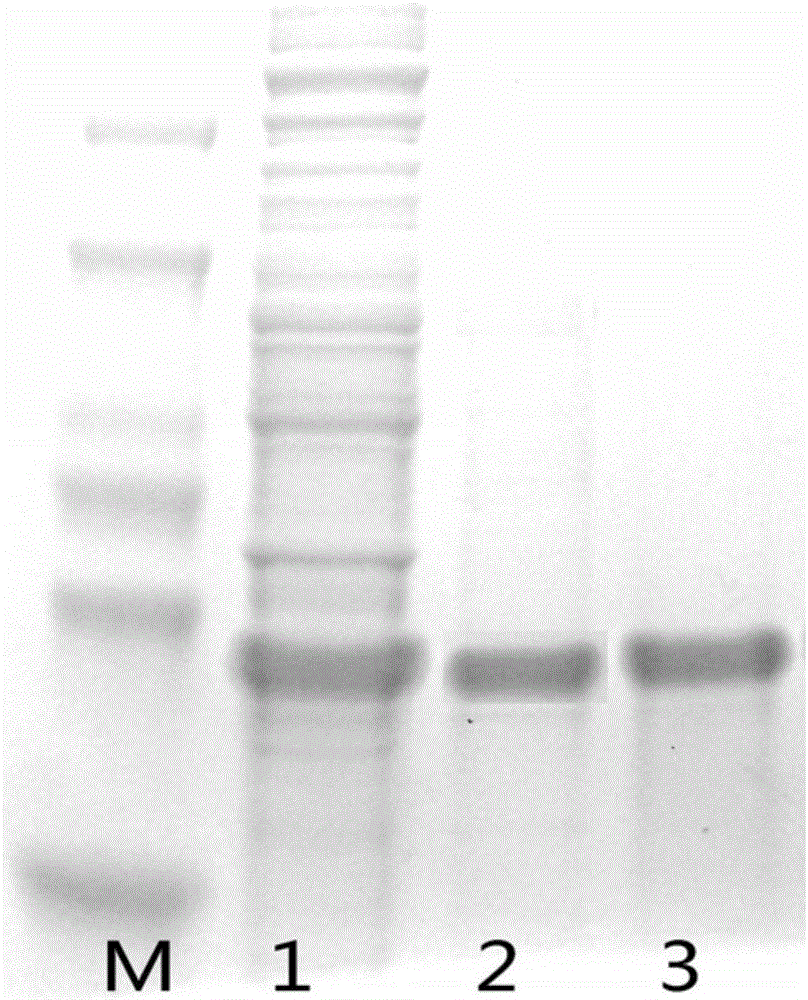

Examples

Embodiment 1

[0021] A preparation method of super-tolerant metal chelate affinity filler Ni Smart Beads 6FF, the preparation method comprises the following steps:

[0022] (1) Amino reaction: Add epichlorohydrin and NaOH solution to the agarose microspheres, and activate with DMSO at 35°C for 2 hours. After activation, clean the agarose microspheres until no epichlorohydrin is present; The pH is 10, and the ligand coupling filler is obtained by reacting at 40°C for 24 hours; the NaOH solution is 2M, the ratio of epichlorohydrin to microspheres is 0.2mg:1g, and the ratio of ligand to microspheres is 100mg: 1g;

[0023] (2) Metal ion chelation

[0024] Add the above coupling ligand filler to 50-100mg / ml NiSO 4 Solution, react at 25°C for 2 hours to obtain super-tolerant metal chelate affinity filler; wherein the ligand structural formula is

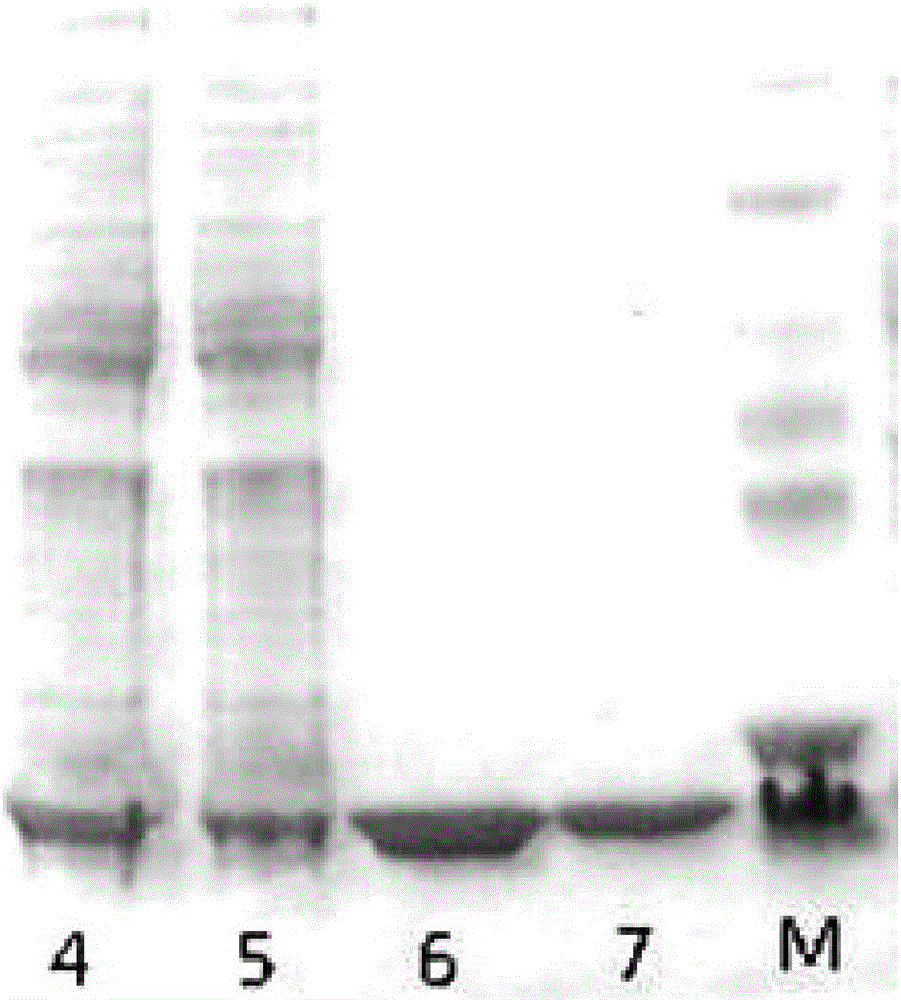

Embodiment 2

[0026] A preparation method of super-tolerant metal chelate affinity filler Co Smart Beads 6FF, the preparation method comprises the following steps:

[0027] (1) Ligand coupling

[0028] Utilize carboxyl reaction: Add epichlorohydrin and NaOH solution to agarose microspheres, shake and activate DMSO at 30°C for 2 hours. After activation, clean the microspheres until there is no epichlorohydrin; , reacted at 30°C for 24 hours to obtain amino-activated fillers; the NaOH solution was 1M, the ratio of epichlorohydrin to microspheres was 0.4mg:1g, and the ratio of amine to microspheres was 0.1mg:1g;

[0029] Dissolve the ligand in 0.1M MES, add the above-mentioned amino-activated filler, add 0.1M EDC when the pH is 5.0, react at 20-30°C for 1 hour, and continue to react for 24 hours when the pH is 5.0 to obtain the coupled ligand filler; among them, The amount of ligand added is 50mg / ml filler;

[0030] (2) Metal ion chelation

[0031] Add the above coupling ligand filler to 10...

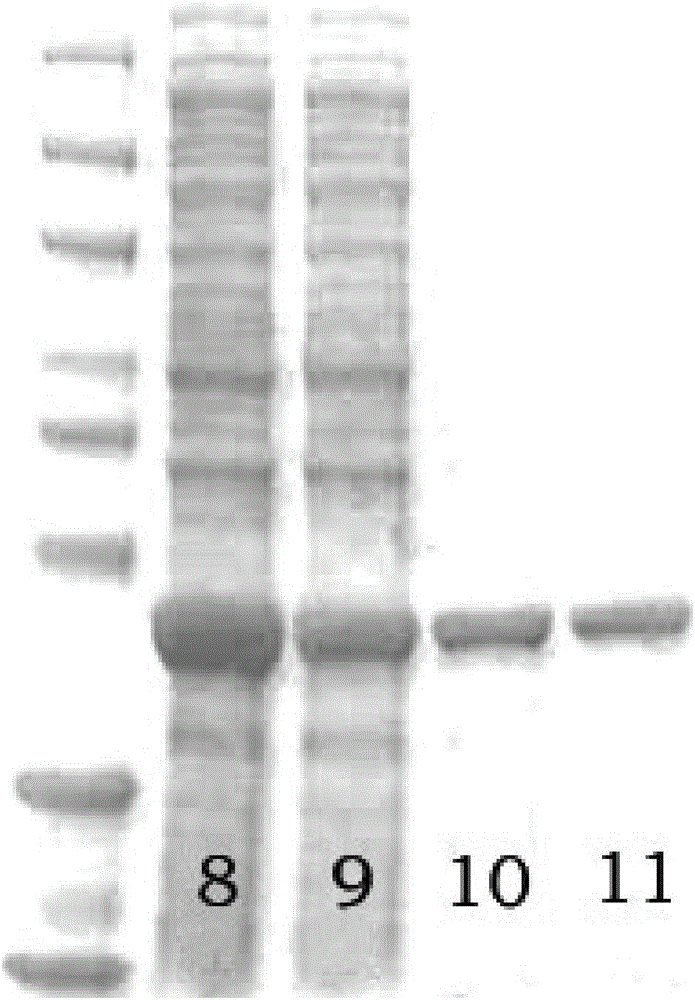

Embodiment 3

[0033] A preparation method of ultra-tolerant metal chelate affinity filler Cu Smart Beads 6FF, the preparation method comprises the following steps:

[0034] (1) Ligand coupling

[0035] Carboxyl reaction: Dissolve the ligand in 0.1M MES, add amino magnetic microspheres, add 0.1MEDC at pH 5.0, react at 20°C for 1 hour, and continue to react at pH 5.0 for 24 hours to obtain a coupled ligand filler; , the amount of ligand added is 100mg / ml filler;

[0036] (2) Metal ion chelation

[0037] Add the above coupling ligand filler to 75mg / ml CuSO 4 React at 10°C for 8 hours to obtain the super-tolerant metal chelate affinity filler; the structural formula of the ligand is:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com