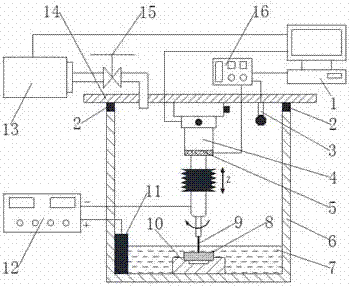

Inflatable pressurized electrochemical discharge machining device and method

A technology of electrical discharge machining and electrochemistry, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of unstable gas film thickness, accelerated gas film layer, and large size of tubular electrodes, etc. Difficult machining problems, reducing electrode loss, and improving the effect of machined surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Install the workpiece 8 on the workbench 10, add the solution 7 into the working chamber 6, and make the workpiece 8 immersed in the solution 7 for more than 2mm. The force sensor 5 is installed on the Z-axis of the X-Y-Z three-coordinate numerical control platform 4, the tool electrode 9 is installed on the chuck below the force sensor 5, and the contact force between the tool electrode 9 and the workpiece 8 is detected by the force sensor, and the data is output To the data acquisition card 16, the air pressure sensor 3 is installed in the working chamber 6, the air pressure in the working chamber 6 is detected by the air pressure sensor 3, and the data is output to the data acquisition card 16, and the data acquisition card 16 uploads the data to the computer; 1 Feed the Z axis of the X-Y-Z three-coordinate numerical control platform 4 downward until it contacts the workpiece 8 to generate a contact force; connect the positive pole of the adjustable puls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com