Antistatic TPU (Thermoplastic Polyurethane) film

An antistatic and thin film technology, applied in the field of antistatic TPU film, can solve the problems of combustion, explosion and discharge, and achieve the effects of improving durability, reducing friction coefficient and eliminating static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

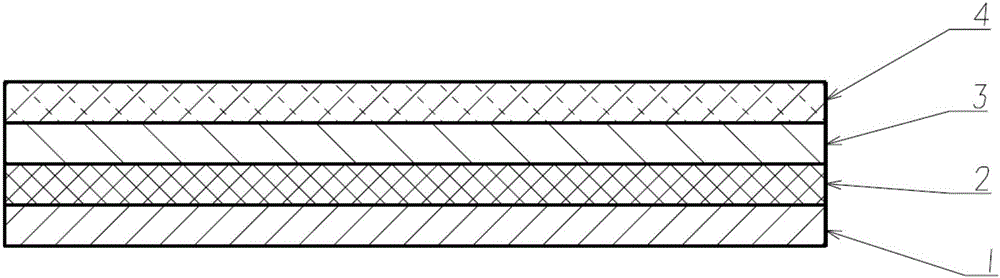

[0023] Such as figure 1 As shown, the antistatic TPU film includes a first conductive layer 1 , a TPU base layer 2 , a second conductive layer 3 , and a wear-resistant layer 4 from bottom to top.

[0024] The thickness of the first conductive layer 1 is 10 μm, and the surface resistivity is 1×10 4 Ω; the thickness of the TPU base layer 2 is 100 μm, the thickness of the second conductive layer 3 is 10 μm, and the surface resistivity is 1×10 4 Ω; the thickness of the wear-resistant layer 4 is 10 μm.

[0025] The first conductive layer 1 and the second conductive layer 3 are each a TPU layer with carbon nanotubes attached; the wear-resistant layer 4 is a TPU layer with an anti-friction agent attached.

[0026] Antistatic TPU film is made by the following method:

[0027] (1) Make the first conductive masterbatch that is added with carbon nanotube: get TPU matrix material and carbon nanotube, the addition amount of carbon nanotube is 5%, wherein also can add additives such as l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com