Electromagnetic shielding film and preparation method thereof

A technology of electromagnetic shielding film and release film, applied in chemical instruments and methods, conductive coatings, lamination, etc., can solve the problems of expensive equipment, large production space, large production cost, etc., to reduce production space and production efficiency. High and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

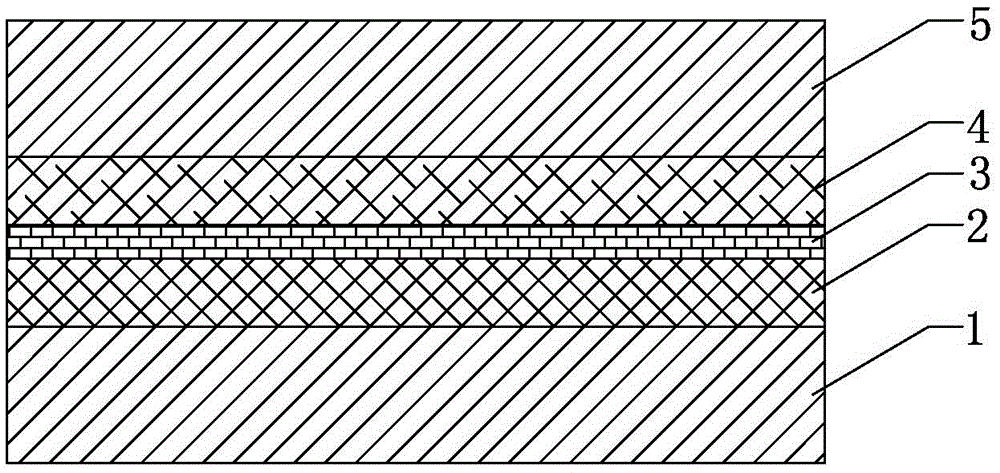

[0032] An electromagnetic shielding film, comprising a carrier film 1, an insulating layer 2, a metal layer 3, a conductive adhesive layer 4 and a release film 5 arranged sequentially from bottom to top, the lower surface and the upper surface of the insulating layer 2 are respectively connected to the carrier film 1 The upper surface of the conductive adhesive layer 4 is attached to the lower surface of the metal layer 3, and the lower surface and the upper surface of the conductive adhesive layer 4 are respectively attached to the upper surface of the metal layer 3 and the lower surface of the release film 5.

[0033] The carrier film 1 is a PET film; the release film 5 is a PET release film 5 with a release force of 5 gf; the thickness of the carrier film 1 is 20 μm; the thickness of the insulating layer 2 is 2 μm; The thickness of the metal layer 3 is 0.2 μm; the thickness of the conductive adhesive layer 4 is 7 μm; the thickness of the release film 5 is 20 μm.

[0034] Th...

Embodiment 2

[0047] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0048] The release film 5 is a PE release film 5 with a release force of 6 gf; the thickness of the carrier film 1 is 40 μm; the thickness of the insulating layer 2 is 4 μm; the thickness of the metal layer 3 is 0.5 μm; The thickness of the conductive adhesive layer 4 is 9 μm; the thickness of the release film 5 is 40 μm.

[0049] The insulating layer 2 is prepared by coating an insulating paint, and the insulating paint is composed of the following raw materials in parts by weight: 100 parts of resin and 2 parts of light-absorbing material.

[0050] The resin is epoxy resin.

[0051] The light-absorbing material is graphite, and the particle size of the light-absorbing material is 1 μm.

[0052] The metal layer 3 is prepared by coating copper ink, and the copper ink is a copper chelate obtained by reacting copper nitrate and ammonium carbamate compounds.

[0053] The conductive adhesiv...

Embodiment 3

[0057] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0058]The release film 5 is an OPP release film 5 with a release force of 8 gf; the thickness of the carrier film 1 is 60 μm; the thickness of the insulating layer 2 is 6 μm; the thickness of the metal layer 3 is 0.8 μm; The thickness of the conductive adhesive layer 4 is 11 μm; the thickness of the release film 5 is 60 μm.

[0059] The insulating layer 2 is prepared by coating an insulating paint, and the insulating paint is composed of the following raw materials in parts by weight: 100 parts of resin and 3 parts of light-absorbing material.

[0060] The resin is polyurethane resin.

[0061] The light-absorbing material is iron oxide black, and the particle size of the light-absorbing material is 0.5 μm.

[0062] The metal layer 3 is prepared by coating copper ink, and the copper ink is a copper chelate obtained by reacting copper nitrate and ammonium carbamate compounds.

[0063] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com