Nanomaterial used as supercapacitor electrode material, and preparation method thereof

A technology of supercapacitors and nanomaterials, applied in hybrid capacitor electrodes, metal selenide/telluride, binary selenium/telluride compounds, etc., can solve the problems of high resistivity, low resistivity, and low carbon materials of sulfides. To achieve the effect of increasing the specific surface area, increasing the contact space, and increasing the specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

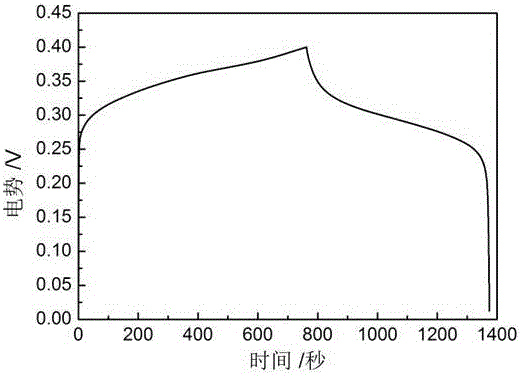

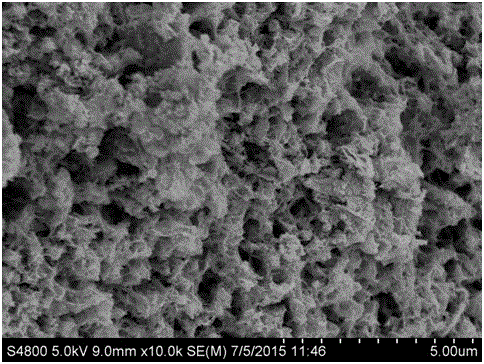

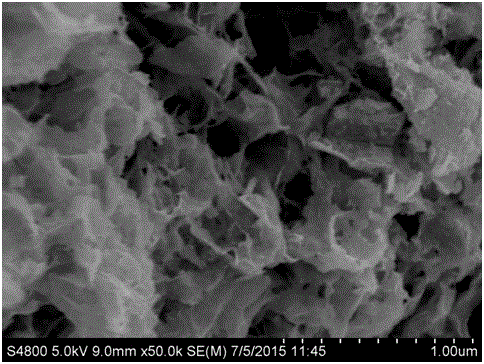

[0029] The raw material 1mmolCo(NO 3 ) 2 ·6H 2 O and 1 mmol Na 2 SeO 3Dissolve in 72ml of deionized water, stir evenly at room temperature and place in a reaction kettle, add 8ml of hydrazine hydrate, then immerse the substrate into the solution in the reaction kettle, and then place the reaction kettle in an oven for hydrothermal synthesis reaction , the reaction temperature was 140 °C, the reaction time was 24 hours, and the final product Co 0.85 Se nanomaterials.

Embodiment 2

[0031] The raw material 2mmolCo(NO 3 ) 2 ·6H 2 O and 2 mmol Na 2 SeO 3 Dissolve in 72ml of deionized water, stir evenly at room temperature and place in a reaction kettle, add 10ml of hydrazine hydrate, then immerse the substrate into the solution in the reaction kettle, and then place the reaction kettle in an oven for hydrothermal synthesis reaction , the reaction temperature was 160 °C, the reaction time was 24 hours, and the final product Co 0.85 Se nanomaterials.

Embodiment 3

[0033] The raw material 0.5mmolCo(NO 3 ) 2 ·6H 2 O and 0.5 mmol Na 2 SeO 3 Dissolve in 72ml of deionized water, stir evenly at room temperature and place in a reaction kettle, add 6ml of hydrazine hydrate, then immerse the substrate into the solution in the reaction kettle, and then place the reaction kettle in an oven for hydrothermal synthesis reaction , the reaction temperature was 120 °C, and the reaction time was 24 hours to obtain the final product Co 0.85 Se nanomaterials.

[0034] The chemical raw materials used in the above examples Co(NO3) 6H2O, Na 2 SeO 3 and hydrazine hydrate are analytically pure, and the resistance of deionized water is 18.0-18.5MΩ.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com