Method for preparing activated carbon materials

A kind of activated carbon and a technology for preparing activated carbon, applied in the manufacture of hybrid/electric double-layer capacitors, etc., can solve unsatisfactory problems and achieve the effects of reliable principle, broad development prospects, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

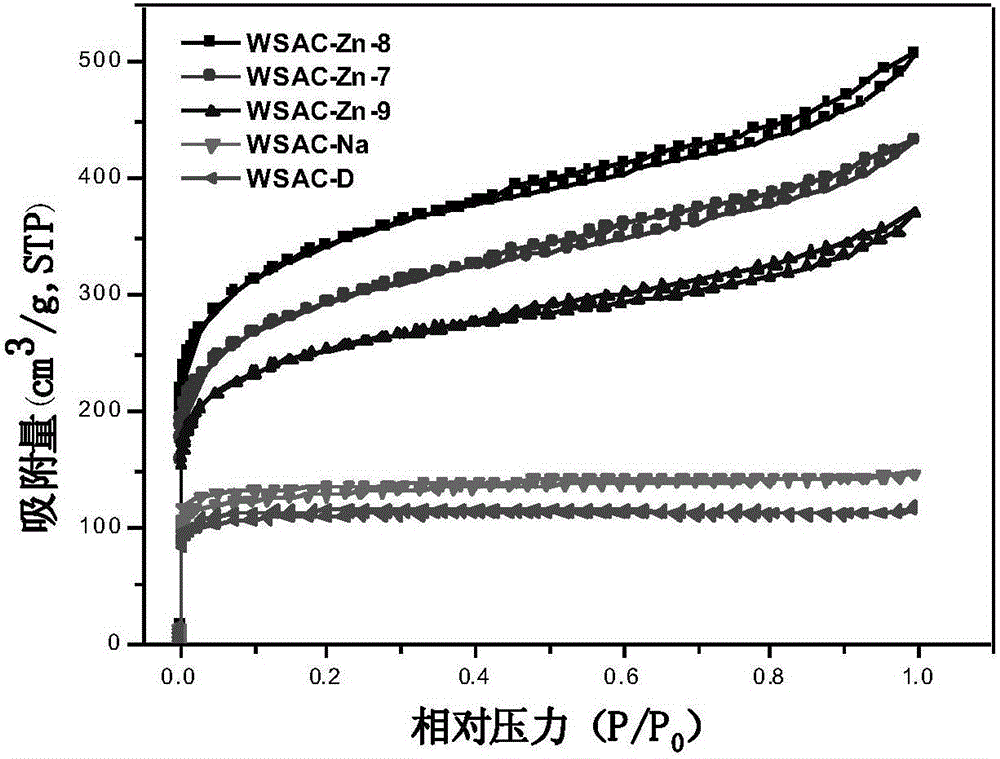

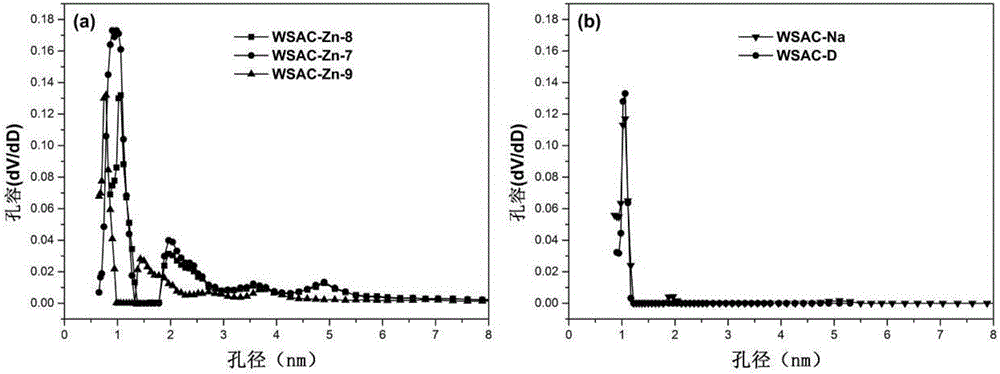

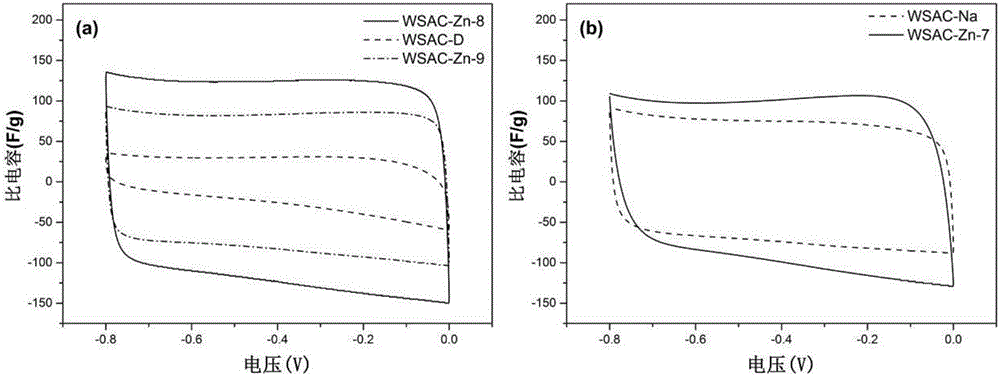

[0018] The preparation process of the activated carbon material involved in this example is as follows: first wash the ordinary walnut shells with double distilled water to remove impurities, dry them at 80°C for 24 hours, and then screen them with a mesh screen with an aperture of 40, and then divide them into 5 parts, each taking 2g, respectively called A1, A2, A3, A4 and A5, put A1 directly into a tubular resistance furnace for carbonization under a nitrogen atmosphere, and then soak it in an aqueous hydrochloric acid solution with a concentration of 5% by mass After 12 hours, wash with double distilled water until neutral and dry, and the obtained activated carbon material is named WSAC-D; soak A2 in 1mol / L sodium hydroxide aqueous solution at 80°C and stir for 24 hours, After washing until neutral, dry it, then put it into a tube-type resistance furnace for carbonization under nitrogen atmosphere, then soak it with 5% hydrochloric acid aqueous solution for 12 hours, wash i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com