Low-dosage environment-friendly rebar corrosion inhibitor

A kind of steel bar rust inhibitor, environmental protection technology, applied in the field of building materials, can solve the problems of reducing concrete mixing performance and slump, high addition amount, aggravating steel bar corrosion, etc., to achieve obvious anti-rust effect, slow down penetration rate, The effect of reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

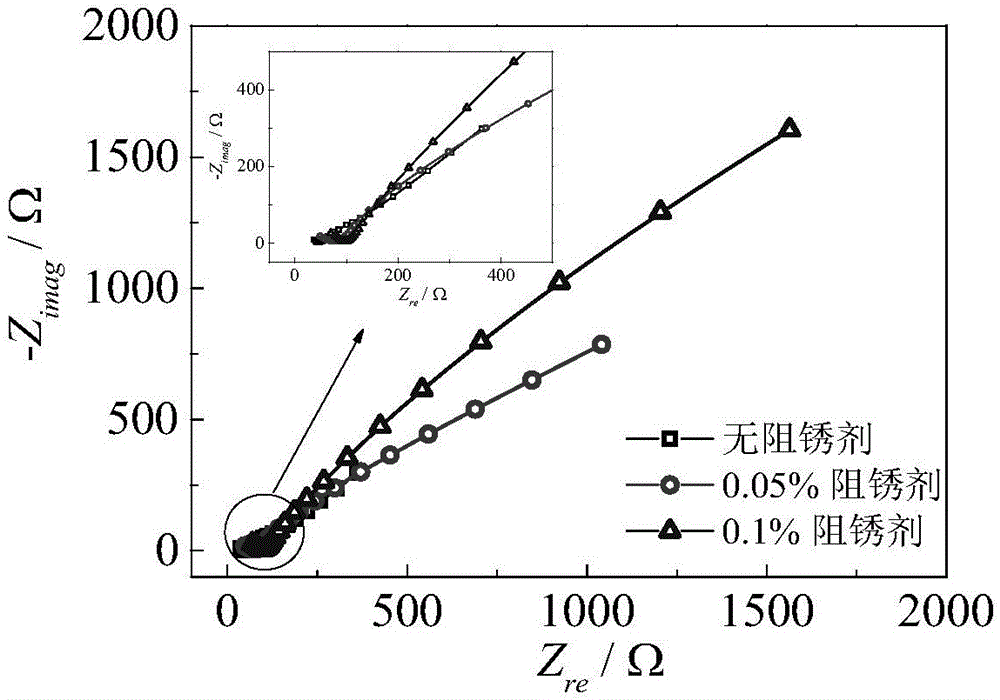

[0015] In Example 1, sodium monofluorophosphate, sodium pyrophosphate, sodium hexametaphosphate, and aluminum tripolyphosphate were mixed in a mass ratio of 10%, 30%, 50%, and 10% to prepare a rust inhibitor.

[0016] In this embodiment, the rust inhibitor is directly mixed in the concrete in the form of powder or dissolved in water and then mixed to prepare the concrete; for the general industrial environment, the dosage is 4 kg / m 3 For harsh corrosive environments such as oceans and salt lakes, the dosage is 6 kg / m 3 .

Embodiment 2

[0017] In Example 2, sodium monofluorophosphate, sodium pyrophosphate, sodium hexametaphosphate, and aluminum tripolyphosphate were mixed in a mass ratio of 5%, 15%, 25%, and 55% to prepare a rust inhibitor.

[0018] In this embodiment, the rust inhibitor is directly mixed in the concrete in the form of powder or dissolved in water and then mixed to prepare the concrete; for the general industrial environment, the dosage is 4 kg / m 3 For harsh corrosive environments such as oceans and salt lakes, the dosage is 10 kg / m 3 .

Embodiment 3

[0019] In Example 3, sodium pyrophosphate, sodium hexametaphosphate, and aluminum tripolyphosphate were mixed in a mass ratio of 10%, 20%, and 70% to prepare a rust inhibitor.

[0020] In this embodiment, the rust inhibitor is directly mixed in the concrete in the form of powder or dissolved in water and then mixed to prepare the concrete; for the general industrial environment, the mixing amount is 6 kg / m 3 For harsh corrosive environments such as oceans and salt lakes, the dosage is 10 kg / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com