Method for recovering isooctyl thioglycolate from cauldron bottom residues

A technology of isooctyl acetate and bottom liquid, which is applied in the direction of mercaptan preparation and organic chemistry, can solve the problems of cumbersome process, high processing cost and complicated process, and achieve the reduction of pollution, reduction of processing cost and improvement of yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

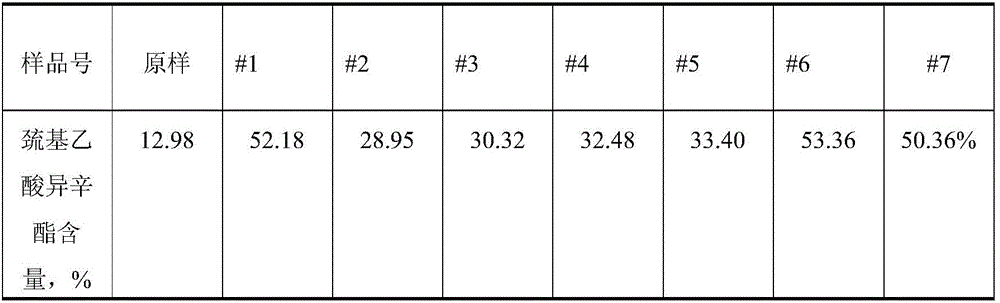

Examples

Embodiment 1

[0031] The treatment method of the bottom liquid of isooctyl thioglycolate distillation is formed by reduction reaction of the following raw materials in parts by mass: 20 parts of bottom liquid, 4.0 parts of zinc powder, and 23.0 parts of hydrochloric acid, wherein the concentration of hydrochloric acid is 30%. .

[0032] Wherein, the raffinate is the light brown liquid produced in the distillation process of isooctyl thioglycolate, and its main components are octanol, isooctyl thioglycolate and their oxidation and polymerization products.

[0033] The processing method includes the following steps:

[0034] (1) 4.0 parts of zinc powder are added to 20.0 parts of the raffinate and stirred;

[0035] (2) Add 23.0 parts of hydrochloric acid (30%) dropwise to the solution obtained in step (1) to carry out a reduction reaction, and the dropwise addition time is 1.5 h;

[0036] (3) After the dropwise addition, continue stirring at 20°C for 2.0h;

[0037] (4) Settling and layerin...

Embodiment 2

[0039] The treatment method of isooctyl thioglycolate distillation still bottom residue is formed by reduction reaction of the following raw materials in parts by mass: 22 parts of still bottom residue, 4.0 parts of iron powder, 23.0 parts of sulfuric acid, wherein the concentration of sulfuric acid is 15% ,

[0040] Wherein, the raffinate is the light brown liquid produced in the distillation process of isooctyl thioglycolate, and its main components are octanol, isooctyl thioglycolate and their oxidation and polymerization products.

[0041] The processing method includes the following steps:

[0042] (1) 4.0 parts of iron powder are added to 22.0 parts of the raffinate and stirred;

[0043] (2) Add 23.0 parts of sulfuric acid (15%) dropwise to the solution obtained in step (1) to carry out a reduction reaction for 1.0 hours of dropping time;

[0044] (3) After the dropwise addition, continue stirring at 20°C for 2.0h;

[0045] (4) Settling and layering, separating the or...

Embodiment 3

[0047] The treatment method of isooctyl thioglycolate distillation still bottom residue is formed by reduction reaction of the following raw materials in parts by mass: 25 parts of still bottom residue, 2.0 parts of zinc powder+3.0 parts of iron powder, 30.0 parts of acetic acid, of which The concentration is 30%.

[0048] Wherein, the raffinate is the light brown liquid produced in the distillation process of isooctyl thioglycolate, and its main components are octanol, isooctyl thioglycolate and their oxidation and polymerization products.

[0049] The processing method includes the following steps:

[0050] (1) 2.0 parts of zinc powder and 3.0 parts of iron powder are added to 25.0 parts of the raffinate and stirred;

[0051] (2) Add 30.0 parts of acetic acid (30%) dropwise to the solution obtained in step (1) to carry out reduction reaction, and the dropwise addition time is 1.5h;

[0052] (3) After the dropwise addition, continue stirring at 25°C for 2.0h;

[0053] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com