Method for extracting solanesol, cembrane diterpene, vitamin E and phytosterol from tobaccos simultaneously

A technology of cembrane diterpene and phytosterol, which is applied in the field of extracting vitamin E, cembrane diterpene, phytosterol, and solanesol at the same time, can solve the problems of waste of fat-soluble active ingredients, so as to improve the utilization value, realize utilization, The effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

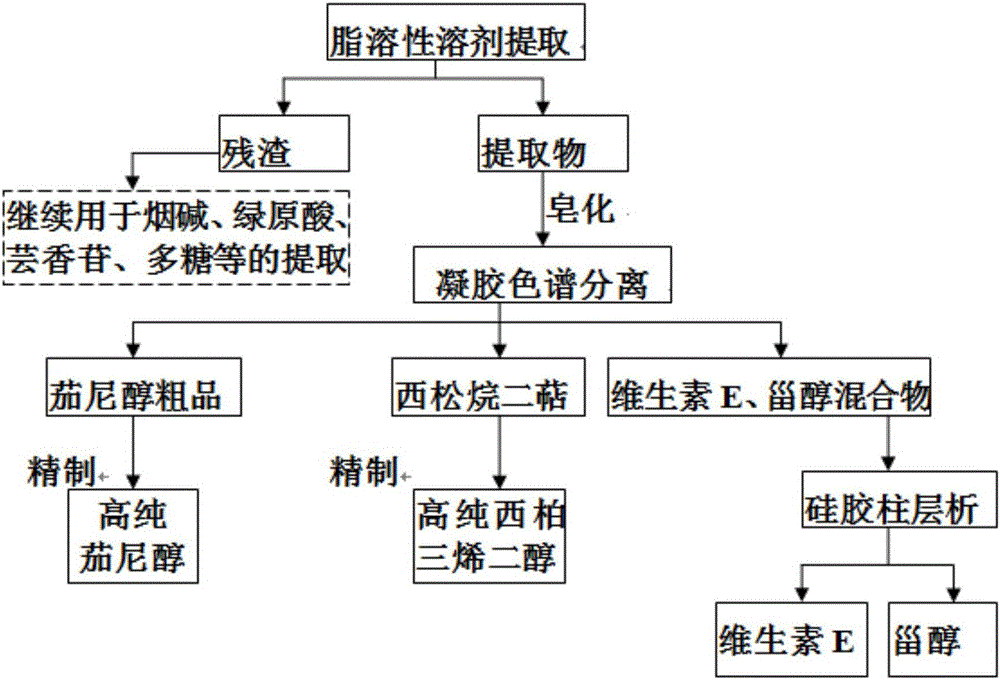

[0030] Such as figure 1 Shown, a kind of method for simultaneously extracting solanesol, cembrane diterpene, vitamin E, phytosterol from tobacco, specifically comprises the steps:

[0031] (1) Extraction: Take the prepared low-grade flue-cured tobacco leaves, dry them at 60°C, crush them, weigh 200g of the crushed tobacco powder, use n-hexane as the extractant, the ratio of solid to liquid is 1:10, ultrasonically extract at 45°C for 30min, centrifuge Or filter, and the residue is washed twice with the extract (the ratio of solid to liquid twice is 1:8, 1:6 respectively), the extract is combined, concentrated under reduced pressure and the solvent is recovered to obtain 12.5g extract;

[0032] (2) Saponification: Add 120mL of 95% ethanol and 2g of sodium hydroxide to the extract obtained in the above steps, and heat and reflux saponification at 60°C for 1h. After the saponification is completed, adjust the pH value to neutral and concentrate to remove the organic solvent. Add ...

Embodiment 2

[0038] Such as figure 1 Shown, a kind of method for simultaneously extracting solanesol, cembrane diterpene, vitamin E, phytosterol from tobacco, specifically comprises the steps:

[0039] (1) Extraction: take the unsuitable lower or upper part of flue-cured tobacco in the mature stage of the field, dry it at 60° C., grind it, weigh 200 g of the ground tobacco powder, use petroleum ether as the extractant, and the remaining steps are the same as in Example 1;

[0040] (2) Saponification: the used extraction solvent for extracting the fat-soluble active ingredient after saponification is completed in this saponification process is sherwood oil, and all the other steps are with implementation example 1.

[0041] Following separation steps are the same as implementation example 1.

Embodiment 3

[0043] Such as figure 1 Shown, a kind of method for simultaneously extracting solanesol, cembrane diterpene, vitamin E, phytosterol from tobacco, specifically comprises the steps:

[0044] (1) Extraction: take mature sun-cured tobacco leaves, dry at 60° C., pulverize, weigh 200 g of pulverized tobacco dust, and use petroleum ether as the extractant. The following steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com