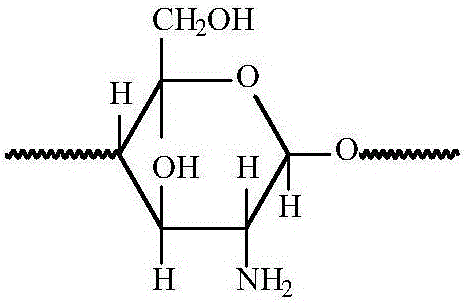

Temperature sensitive chitosan flocculant and preparing method and application thereof

A chitosan and sensitive technology, which is applied in the field of temperature-sensitive chitosan flocculant and its preparation, can solve the problems of limited application scope, no temperature sensitivity of temperature switch, and no secondary pollution risk. , Excellent flocculation ability, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

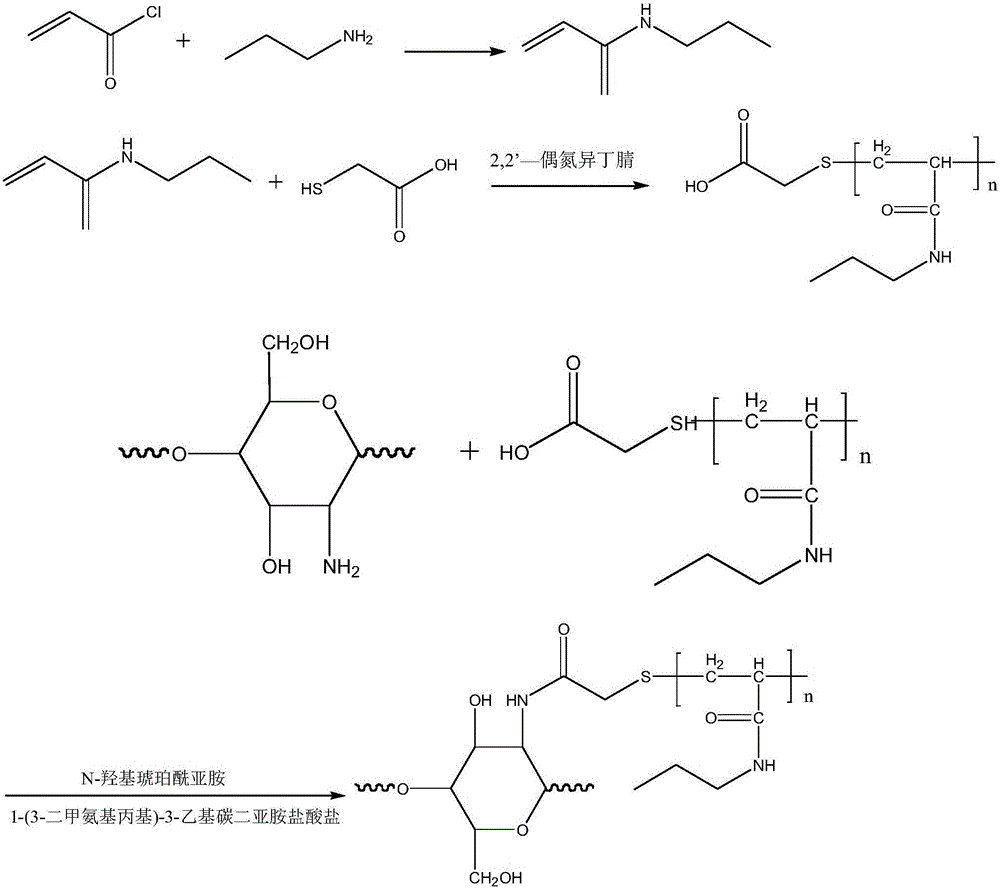

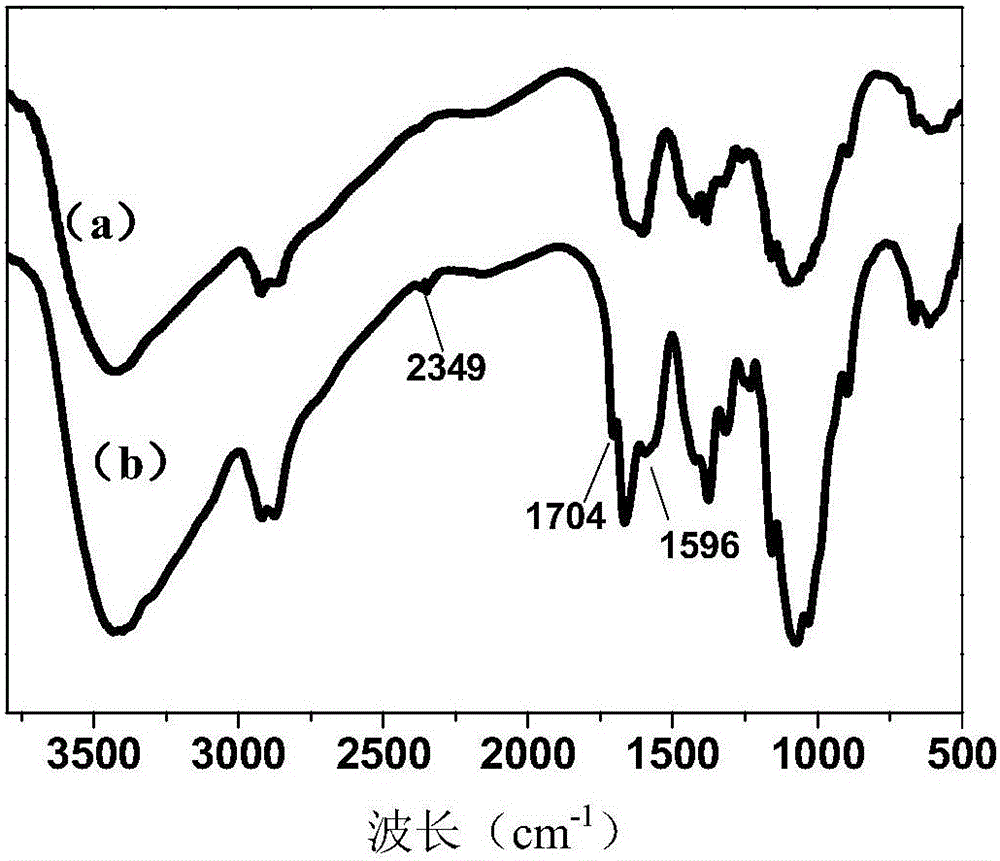

Method used

Image

Examples

Embodiment 1

[0054] Acryloyl chloride, n-propylamine and triethylamine were respectively dissolved in toluene (wherein the molar ratio of acryloyl chloride, n-propylamine and triethylamine was 1:1.1:1.2) for use. At 4°C, the acryloyl chloride solution was slowly added dropwise to a mixed solution of n-propylamine and triethylamine (solvent is toluene) with stirring for 1 hour, and then the mixture was stirred and reacted at 25°C for 24 hours. The reaction mixture was filtered to remove the resulting precipitate, resulting in a monomer (in toluene) solution. Thioglycolic acid was dissolved in toluene (the molar ratio of acryloyl chloride and thioglycolic acid was 20:1), placed in a round-bottomed flask, and stirred to dissolve completely. The temperature was raised to 60 °C, and nitrogen was introduced for 30 min to remove the oxygen in the solution. Add 2,2'-azoisobutyronitrile (AIBN for short, the solvent is toluene, the molar mass ratio of 2,2'-azoisobutyronitrile to acryloyl chloride i...

Embodiment 2

[0057] Acryloyl chloride, n-propylamine and triethylamine were respectively dissolved in toluene (wherein the molar ratio of acryloyl chloride, n-propylamine and triethylamine was 1:1.2:2) for use. The acryloyl chloride solution was slowly added dropwise to a mixed solution of n-propylamine and triethylamine (solvent is toluene) at 4°C for 1 hour while stirring, and then the mixture was stirred at 30°C for 12 hours. The reaction mixture was filtered to remove the resulting precipitate, resulting in a monomer (in toluene) solution. Thioglycolic acid was dissolved in toluene (the molar ratio of acryloyl chloride and thioglycolic acid was 18:1), placed in a round-bottomed flask, and stirred to dissolve completely. The temperature was raised to 70°C, and nitrogen gas was introduced for 30min to remove the oxygen in the solution. Add 2,2'-azoisobutyronitrile (solvent is toluene, the molar mass ratio of 2,2'-azoisobutyronitrile to acryloyl chloride is 1:3, solvent and 2,2'-azoisobuty...

Embodiment 3

[0060] Acryloyl chloride, n-propylamine and triethylamine were respectively dissolved in toluene (wherein the molar ratio of acryloyl chloride, n-propylamine and triethylamine was 1:1.3:1.4) for use. The acryloyl chloride solution was slowly added dropwise to a mixed solution of n-propylamine and triethylamine (solvent is toluene) at 4°C for 1 hour while stirring, and then the mixture was stirred at 23°C for 15 hours. The reaction mixture was filtered to remove the resulting precipitate, resulting in a monomer (in toluene) solution. Thioglycolic acid was dissolved in toluene (the molar ratio of acryloyl chloride to thioglycolic acid was 16:1), placed in a round-bottomed flask, and stirred to dissolve completely. The temperature was raised to 80°C, and nitrogen gas was introduced for 30min to remove the oxygen in the solution. Add 2,2'-azoisobutyronitrile (solvent is toluene, the molar mass ratio of 2,2'-azoisobutyronitrile to acryloyl chloride is 1:4, solvent and 2,2'-azoisob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com