A kind of magnetic content coded polymer carrier microsphere and its preparation method

A polymer and polymer solution technology, which is applied in the preparation of microspheres, magnetic objects, microcapsule preparations, etc., can solve the problems of indistinguishable coding signals from detection signals, light fading, etc., and achieve low cost, large coding volume, and translation The effect of code simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

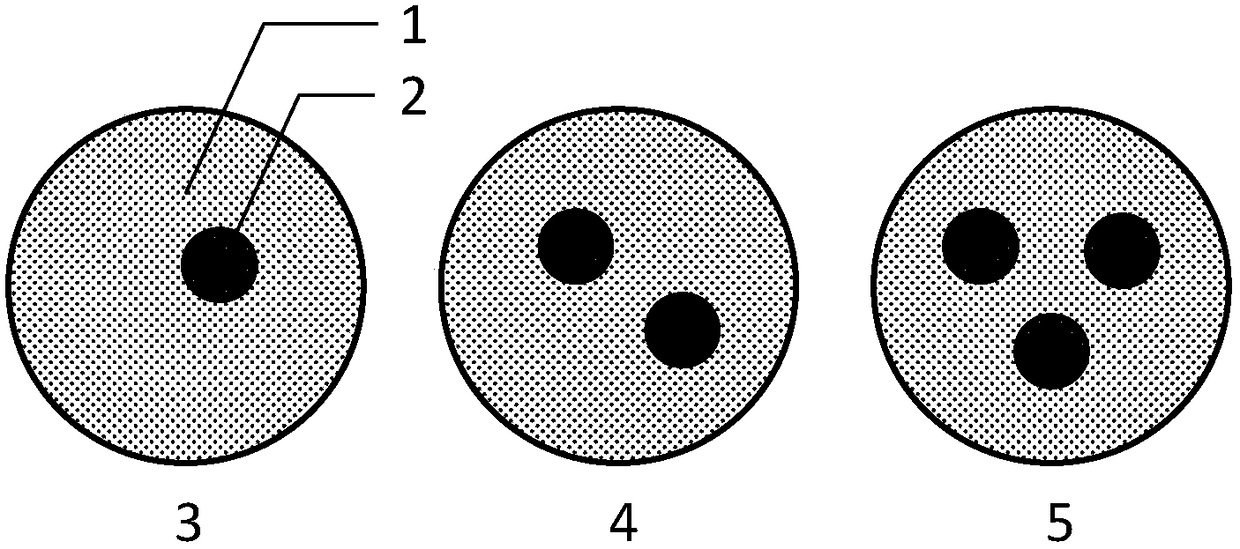

[0034] Embodiment 1 Preparation of three differently coded magnetic polystyrene carrier microspheres:

[0035] 1. Polystyrene is dissolved in toluene to form a toluene solution of polystyrene, wherein the concentration of polystyrene in the solution is 0.2 g / mL.

[0036] 2. Add iron ferric oxide particles with an average particle size of 7nm to the polystyrene solution at a ratio of 20mg / mL, 40mg / mL, and 60mg / mL, and disperse evenly, and configure three different magnetic nanoparticle contents polystyrene toluene solution.

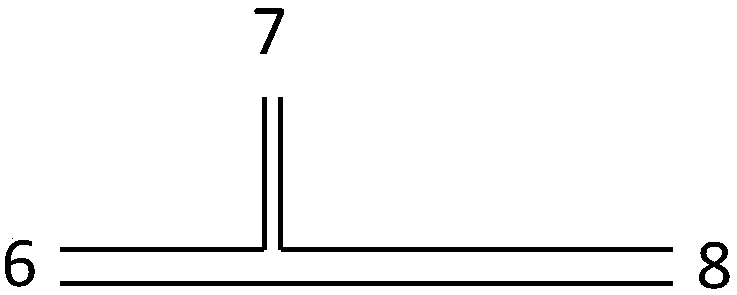

[0037] 3. Inject 3% polyvinyl alcohol solution into the three-way inlet A of the droplet generation device through a syringe pump, and inject a polystyrene toluene solution with a magnetic nanoparticle content of 20 mg / mL into inlet B to adjust the flow rate of the two-phase solution Let it form a uniform drop, and then receive the drop with a 3% polyvinyl alcohol solution at the outlet of the tee. Polystyrene toluene droplets with magnetic nanoparticles...

Embodiment 2 10

[0039] Example 2 Preparation of ten different coded magnetic polystyrene carrier microspheres:

[0040] 1. Polystyrene is dissolved in toluene to form a toluene solution of polystyrene, wherein the concentration of polystyrene in the solution is 0.2 g / mL.

[0041] 2. Diferric iron tetroxide particles with an average particle size of 7nm were prepared at 10mg / mL, 20mg / mL, 30mg / mL, 40mg / mL, 50mg / mL, 60mg / mL, 70mg / mL, 80mg / mL, 90mg / mL mL, 100mg / mL ratio was added to the polystyrene solution, and dispersed evenly, and configured into three polystyrene toluene solutions with different magnetic nanoparticle contents.

[0042] 3. Inject 3% polyvinyl alcohol solution into the three-way inlet A of the droplet generating device through a syringe pump, and inject a polystyrene toluene solution with a magnetic nanoparticle content of 10 mg / mL into inlet B to adjust the flow rate of the two-phase solution Let it form a uniform drop, and then receive the drop with a 3% polyvinyl alcohol so...

Embodiment 3

[0044] Example 3 Preparation of three differently coded magnetic polymethyl methacrylate carrier microspheres:

[0045] 1. Polymethyl methacrylate is dissolved in N, and the DMF solution that forms polymethyl methacrylate in N-methyl formamide (DMF), wherein the concentration of polymethyl methacrylate in the solution is 0.2g / mL.

[0046] 2. Add iron ferric oxide particles with an average particle size of 7nm to the polymethyl methacrylate solution at the ratio of 20mg / mL, 40mg / mL, and 60mg / mL, and disperse evenly, and configure three different magnetic Nanoparticle content in PMMA DMF solution.

[0047] 3. Inject 500cst of silicone oil into the tee inlet A of the droplet generating device through a syringe pump, and inject a polymethyl methacrylate DMF solution with a magnetic nanoparticle content of 20mg / mL in the inlet B, and adjust the flow rate of the two-phase solution so that Form a uniform droplet, and then receive the droplet with 500cst of silicone oil at the outl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com