High-strength bridge support seat sliding plate for high-speed rail

A bridge bearing, high-strength technology, used in bridges, bridge parts, bridge construction and other directions, can solve the problems of difficult support processing, affecting service life, easy to rust, etc., to increase support capacity, increase buffer effect, reduce The effect of oil storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

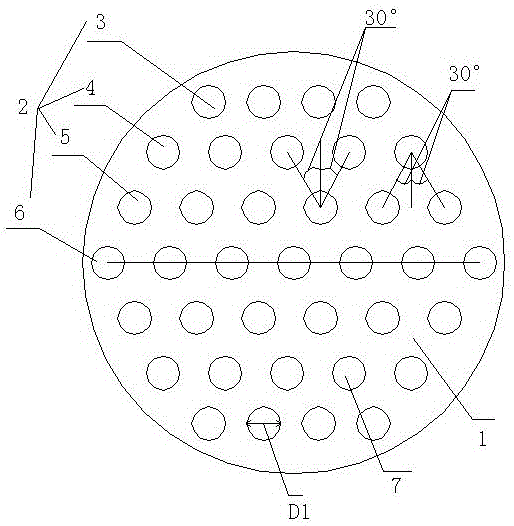

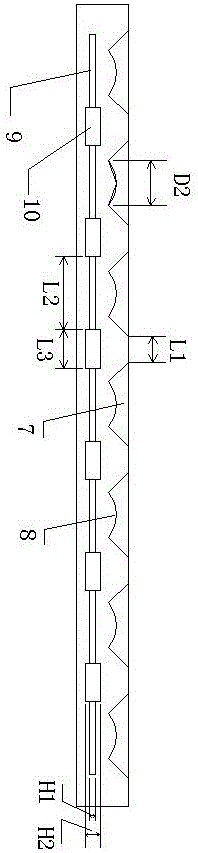

Image

Examples

Embodiment 1

[0031] The manufacturing steps of a high-strength bridge support skateboard for high-speed rail are as follows:

[0032] (1) Prepare lubricant, mix polysilicone, oleamide, pentaerythritol stearate and methyl silicone oil in a mass ratio of 1:3:4:7 at room temperature, the mixing time is 15min, and the mixing speed is 45r / min, get lubricant;

[0033] (2) Prepare the solubilizer, mix acrylic acid and polyethylene glycol at a mass ratio of 4:1, the mixing time is 18min, and the mixing speed is 30r / min to obtain the solubilizer;

[0034] (3) Pre-mixing, in parts by weight, mix 100 parts of ultra-high molecular weight polyethylene with a molecular weight of 9.2 million, 2 parts of lubricant, 0.5 parts of silicone oil, 2 parts of nano titanium carbide with a particle size of 5 nanometers, and 1 part of disulfide Molybdenum and 0.3 parts of solubilizer are added to a high-speed mixer and stirred to obtain a premixed mixture;

[0035] (4) Blending and extrusion, adding the premixed mixture ...

Embodiment 2

[0039] The manufacturing steps of a high-strength bridge support skateboard for high-speed rail are as follows:

[0040] (1) Prepare lubricant, mix polysilicone, oleamide, pentaerythritol stearate and methyl silicone oil in a mass ratio of 1:2:5:1 at room temperature, mixing time is 15min, mixing speed is 45r / min, get lubricant;

[0041] (2) Prepare the solubilizer, mix acrylic acid and polyethylene glycol in a mass ratio of 2:3, the mixing time is 18min, and the mixing speed is 30r / min to obtain the solubilizer;

[0042] (3) Pre-mixing, in parts by weight, mix 100 parts of ultra-high molecular weight polyethylene with a molecular weight of 9.2 million, 10 parts of lubricant, 1 part of silicone oil, 10 parts of nano titanium carbide with a particle size of 60 nanometers, and 5 parts of disulfide Molybdenum and 0.5 parts of solubilizer are added to a high-speed mixer and stirred to obtain a premixed mixture;

[0043] (4) Blending extrusion, adding the pre-mixed mixture to the twin-sc...

Embodiment 3

[0047] The manufacturing steps of a high-strength bridge support skateboard for high-speed rail are as follows:

[0048] (1) Prepare lubricant, mix polysilicone, oleamide, pentaerythritol stearate and methyl silicone oil in a mass ratio of 1:5:2:3 at room temperature, the mixing time is 15min, and the mixing speed is 45r / min, get lubricant;

[0049] (2) Prepare the solubilizer, mix acrylic acid and polyethylene glycol in a mass ratio of 5:2, the mixing time is 18min, and the mixing speed is 30r / min to obtain the solubilizer;

[0050] (3) Pre-mixing, by weight, 100 parts of ultra-high molecular weight polyethylene with a molecular weight of 9.2 million, 7 parts of lubricant, 0.7 parts of silicone oil, 5 parts of nano titanium carbide with a particle size of 40 nanometers, and 3 parts of disulfide Molybdenum and 0.4 parts of solubilizer are added to a high-speed mixer and stirred to obtain a premixed mixture;

[0051] (4) Blending and extrusion, adding the pre-mixed mixture to the twi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com