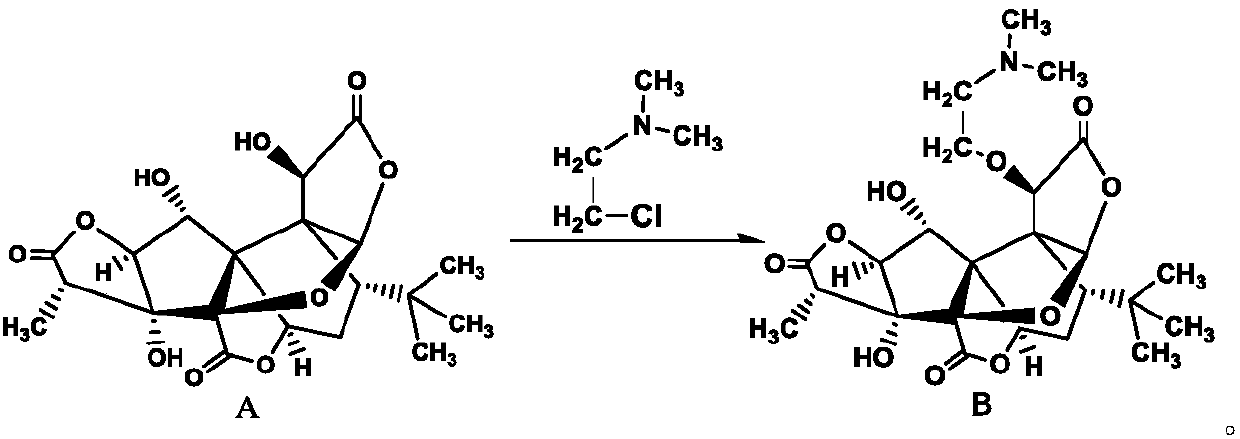

A kind of method adopting micro flow field reactor to prepare dimethylaminoethyl ginkgolide B

A technology of dimethylaminoethyl and dimethylaminoethyl chloride, which is applied in the field of medicine and can solve the problems of long reaction time, high reaction cost, and non-continuous preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

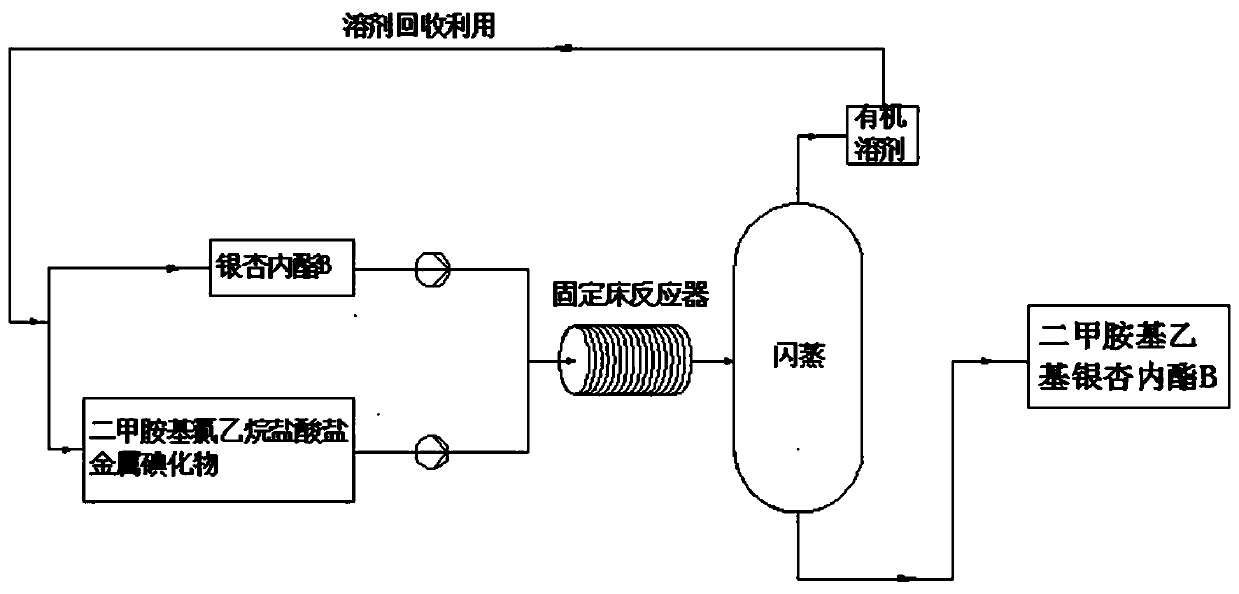

Method used

Image

Examples

Embodiment 1

[0020] Dissolve dimethylaminoethyl chloride ethane hydrochloride and potassium iodide in the mixed solution of acetonitrile and water (the volume ratio of acetonitrile and water is 10%), then pump the acetonitrile solution of ginkgolide B and the above mixture into the In the fixed-bed microchannel modular reaction device of potassium carbonate, the mol ratio of ginkgolide B and dimethylaminoethyl chloride ethyl chloride hydrochloride is 1:1, and the mol ratio of potassium iodide and ginkgolide B is 0.2:1, The molar ratio of potassium carbonate to ginkgolide B is 2:1, the reaction residence time is kept for 4min, and the reaction is carried out at 70°C, the crude product is filtered, the filtrate is concentrated, and the obtained solid is recrystallized with methanol to obtain dimethylaminoethyl Ginkgolide B, the yield was 75%.

Embodiment 2

[0022] Dissolve dimethylaminoethyl chloride ethane hydrochloride and potassium iodide in the mixed solution of tetrahydrofuran and water (the volume ratio of tetrahydrofuran and water is 10%), then pump the tetrahydrofuran solution of ginkgolide B and the above mixture into the In the fixed-bed microchannel modular reaction device of cesium carbonate, the mol ratio of ginkgolide B and dimethylaminoethyl chloride ethyl chloride hydrochloride is 1:1, and the mol ratio of potassium iodide and ginkgolide B is 0.2:1, The molar ratio of cesium carbonate to ginkgolide B is 2:1, the reaction residence time is kept for 4min, and the reaction is carried out at 70°C, the crude product is filtered, the filtrate is concentrated, and the obtained solid is recrystallized with methanol to obtain dimethylaminoethyl Ginkgolide B, the yield was 71%.

Embodiment 3

[0024] Dissolve dimethylaminoethyl chloride hydrochloride and sodium iodide in a mixture of acetone and water (the volume ratio of acetone and water is 10%), then pump the acetone solution of ginkgolide B and the above mixture into In the fixed-bed microchannel modular reaction device that is filled with cesium carbonate, the mol ratio of ginkgolide B and dimethylaminoethyl chloride ethane hydrochloride is 1:1, and the mol ratio of sodium iodide and ginkgolide B is 0.2:1, the molar ratio of cesium carbonate to ginkgolide B is 2:1, keep the reaction residence time for 5min, react at 70°C, filter the crude product, concentrate the filtrate, and recrystallize the obtained solid with methanol to obtain dimethyl Aminoethyl ginkgolide B, the yield was 73%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com