Method for removing free gossypol in cottonseed meal through step-by-step reduction

A technology of free gossypol and cottonseed meal, which is applied in the field of step-by-step reduction of free gossypol in cottonseed meal, can solve the problems of failure to achieve the ideal detoxification rate, waste water discharge pollutes the environment, and low removal efficiency. Broad market application prospects, high dephenolization efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

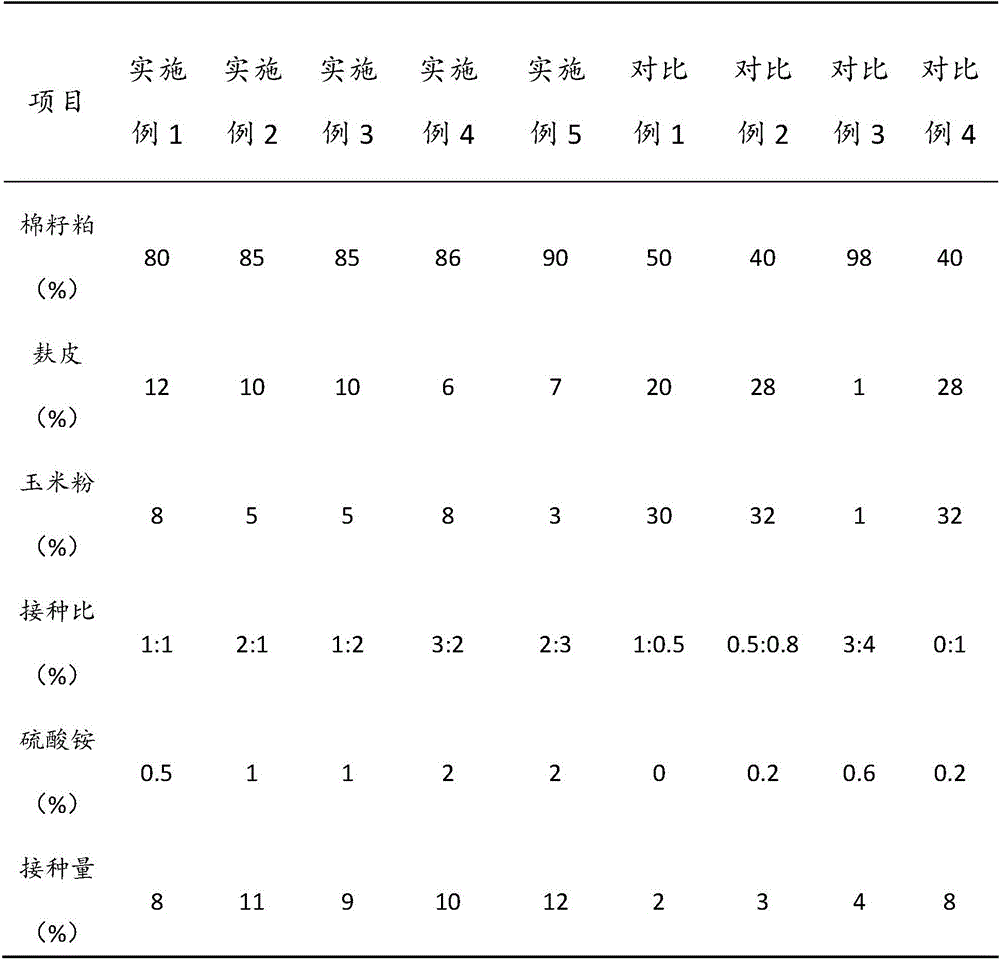

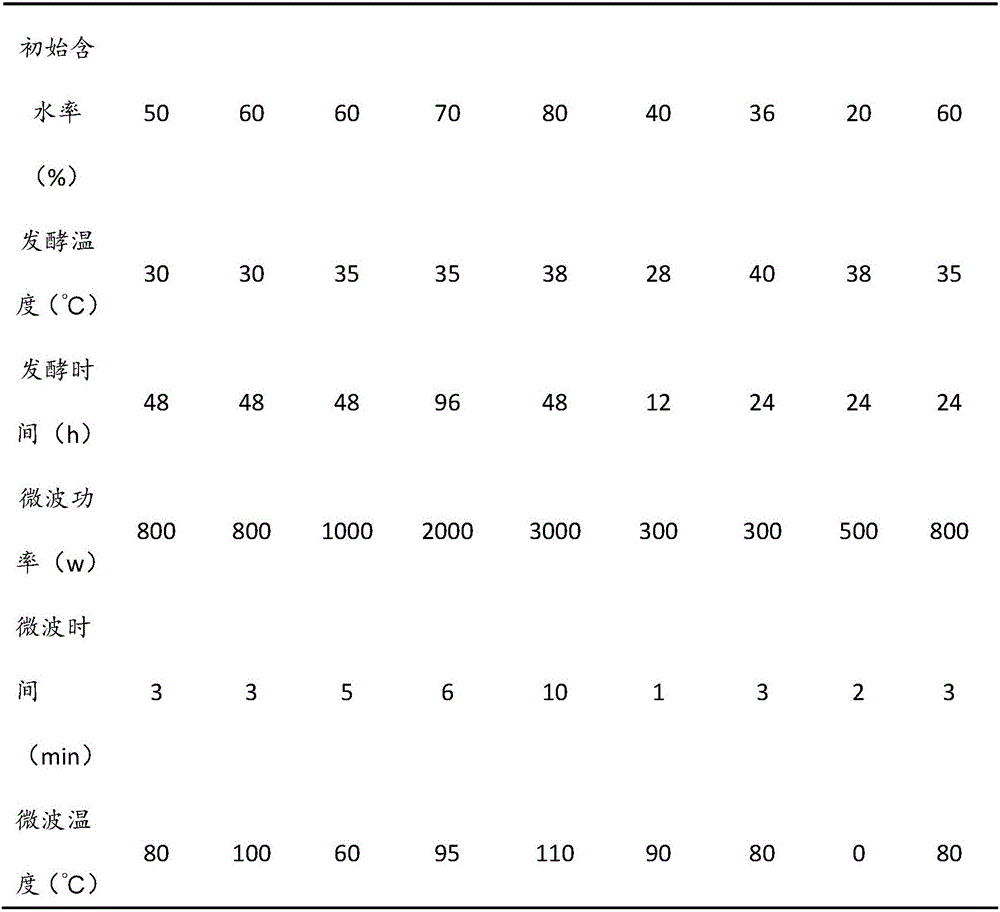

[0021] Embodiment 1, step-by-step method reduce free gossypol content in cottonseed meal. The specific method is as follows, and the percentages are mass percentages:

[0022] Cottonseed meal is sieved with 40 mesh, and 80g of cottonseed meal, 12g of bran, and 8g of corn flour are used as substrates. Bacillus subtilis and yeast strains are activated, Bacillus subtilis and yeast are mixed at a ratio of 1:1, the inoculum size is 6%, ammonium sulfate is added 0.5%, the initial moisture content is 50%, the fermentation temperature is 30°C, and the fermentation time is 48h. After fermentation, the wet-based cottonseed meal is processed by microwave technology. Under the conditions of microwave power of 800w, microwave time of 3min, and microwave temperature of 80°C, the second detoxification treatment is carried out, and then dried, crushed, finished product, and packaged .

Embodiment 2

[0023] Embodiment 2, step-by-step method reduce free gossypol content in cottonseed meal. The specific method is as follows, and the percentages are mass percentages:

[0024] Cottonseed meal is sieved with 40 meshes, and 85g of cottonseed meal, 10g of bran, and 5g of corn flour are used as substrates. Bacillus natto and yeast are activated, Bacillus natto and yeast are mixed at a mass ratio of 2:1, the inoculum size is 8%, uric acid is added 1%, the initial moisture content is 60%, the fermentation temperature is 30°C, and the fermentation time is 48h. After fermentation, the wet-based cottonseed meal is processed by microwave technology. Under the conditions of microwave power of 1000w, microwave time of 3min, and microwave temperature of 100°C, the second detoxification treatment is carried out, and then dried, crushed, finished product, and packaged .

Embodiment 3

[0025] Embodiment 3, step-by-step method reduces the content of free gossypol in cottonseed meal. The specific method is as follows, and the percentages are mass percentages:

[0026] Cottonseed meal is sieved with 40 meshes, and 85g of cottonseed meal, 10g of bran, and 5g of corn flour are used as substrates. Bacillus subtilis and Candida utilis are activated, Bacillus subtilis and Candida utilis are mixed at a ratio of 1:2, the inoculum size is 10%, ammonium sulfate is added 1%, the initial moisture content is 60%, the fermentation temperature is 35°C, and the fermentation Time 48h. After fermentation, the wet-based cottonseed meal is processed by microwave technology. Under the conditions of microwave power of 1000w, microwave time of 5min, and microwave temperature of 60°C, the second detoxification treatment is carried out, and then dried, crushed, finished product, and packaged .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com